Contents

1.Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 244

2.Electrospinning nanofiber technology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 244

2.1. Development history of electrospun nanofibers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 244

2.2. Different electrospinning techniques. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .245

3. Electrospun nanofibers as tissue engineering scaffolds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245

3.1. Ideal scaffold for tissue engineering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245

3.2. Advantages of electrospun nanofibers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .247

4. Electrospun nanofibers for skin tissue regeneration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 247

5. Electrospun nanofibers for blood vessel tissue regeneration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 248

6. Electrospun nanofibers for nerve tissue regeneration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 250

6.1. Simple hollow luminal structure NGC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 250

6.2. Growth factor incorporated into NGC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 251

6.3. Conductive nanofiber NGC and electrical stimulation for nerve regeneration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 251

6.4. Filaments-containing NGC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 252

6.5. Sponge-containing NGC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 252

1. Introduction

Fibers are no stranger to human beings. Natural fibers from plants and animals, including cotton, hemp, wool, and silk, have been used for thousands of years. With the advent of modern polymeric materials, synthetic fibers have increasingly grown in popularity. They continue to be used in a wide variety of applications, including everyday consumer products, environmental applications, optoelectronics, biomedical research and technology, energy, filtration systems, and protective equipment [1]. In recent years, various fabrication methods have emerged to prepare nanofibers, such as phase separation [2], self-assembly [3] stretching, and template synthesis [4]. However, these methods are limited by their technical complexity, cost, yield, and ability to control the scale of the resulting fibers.

As an alternative, Formhals [5] invented a device capable of producing nanoscale polymer fibers using a high-voltage electric field and applied for a patent in 1934. It was the first international patent for the preparation of nanofibers using an electrical potential difference as a driving force, which coined the term electrospinning. Electrospinning provides a simple and straightforward approach to produce continuous, polymer fibers with diameters ranging from nanometers to microns [1], [6]. The typical electrospinning apparatus includes a high-voltage power supply, a syringe pump to control polymer flow rate, a spinneret (e.g., a medical needle with a blunt tip), and a conductive collector to catch the electrospun fibers. Simply, electrospinning can be considered an electrohydrodynamic process dependent on the potential difference to create a liquid jet, followed by mechanical stretching, elongation, and drying to generate fibers [7], [8]. As the fibers collect, an electrospun membrane is built with 3D topography, high porosity, and large surface area, while retaining mechanical integrity and fiber continuity [9]. As such, the unique structure of electrospun membranes have broad applications in many fields but are of particular interest as scaffolds for tissue engineering [10], [11]. This tissue engineering application is because most human tissues and organs are composed of nanofibers in the ECM, which makes it possible for electrospun nanofiber use in tissue and organ repair as a mimic [12], [13]. More importantly, a variety of natural and synthetic polymers can be electrospun that have biocompatibility and biodegradability and are reabsorbed by the human body. Together, these attributes of electrospun nanofibers have attracted the attention of biomedical researchers and led to investigation for use in skin, bone, cartilage, nerve, blood vessel, tendon, and other tissue regeneration applications.

The field of tissue engineering attempts to restore or regenerate the functionality of healthy tissues and organs using the three essential components of cells, biomolecules, and scaffolds [14]. The tissue engineering scaffold provides the 3D microenvironment needed for the growth of cells damaged by disease, injury, or congenital defects, and the selection of the material depends, to a great extent, on the tissue-specific application [15]. However, no matter the intended application, a primary challenge is scaling biomaterials into 3D constructs that recapitulate the biological, chemical, and mechanical properties of the tissue microenvironment [16]. With its relative simplicity and versatility, electrospinning can be a process used to fabricate these 3D porous, fiber membranes resembling the ECM and modified with biomolecules to facilitate cell adhesion, migration, differentiation, and proliferation. Thus, we review here the current advances in the fabrication of electrospun fiber materials and their use as scaffolds for tissue engineering.

2. Electrospinning nanofiber technology

2.1. Development history of electrospun nanofibers

Electrospun nanofibers have existed since the beginning of the 20th century (Table 1). Formhals originally published a series of patents on solution electrospinning using a polymer dissolved in solution to obtain ultrafine fibers in the nanometer to micrometer diameter range. In 1980, the United States Patent Office disclosed another method of electrospinning, polymer melt electrospinning, where the polymer is melted to produce the electrospinning solution [17]. This process results in fibers that are 1-2 orders of magnitude larger than those obtained by solution electrospinning, indicating that it may not be useful for all applications of electrospun fibers [18]. Nonetheless, the invention of both solution and melt electrospinning laid the foundation for the further development and advancement of new technologies.

Table 1 Development history of electrospun nanofibers.

| Particular year | Development of electrospinning technology |

|---|---|

| 1902 | Solution Electrospinning |

| 1980 | Melt Electrospinning |

| 1999 | Preparation of Electrospun Nanocomposites |

| 2000 | Electrospun Nanofibers for Tissue Engineering |

| 2003 | Coaxial Electrospun Nanofibers |

| 2005 | Emulsion Electrospinning Nanofibers |

| 2007 | Dynamic Water Flow Electrospun nanoyarns |

| 2012 | Electrospun Continuous Nanoyarn |

| 2014 | Preparation of three-dimensional porous aerogel by electrospinning combined with freeze-drying technology |

Since the turn of the 21 st century, traditional electrospinning technologies have developed rapidly worldwide in scientific research and industrial circles, partly due to the growing interest by the tissue-engineering field. In 2003, Sun et al. [19] reported on a new electrospinning technology, coaxial electrospun nanofibers with core-shell structure, in which two different solutions are simultaneously ejected through a coaxial nozzle, enabling encapsulation of materials. Building on this technology, Xu et al. [20] reported the core-shell structure of nanofibers containing an anticancer drug by emulsion electrospinning, which does not require a coaxial nozzle, but instead uses the emulsion of a non-spinnable component within a solution that can be electrospun. In an attempt to increase the three-dimensionality of electrospun membranes, Teo et al. [21] created an electrospinning system that incorporated a water vortex to collect the nanofibers, resulting in a highly porous yarn that could be used as a tissue engineering scaffold. Likewise, in 2012, Ali et al. [22] created a system for continuous, electrospun nanoyarns that can be knitted or weaved into tissue engineering scaffolds. Most recently, Si et al. [23] combined electrospinning with freeze-drying to generate a composite material with nanofibers embedded in a 3D porous aerogel. These examples illustrate the progression of electrospinning over the last two decades from simple mats to more complex, 3D structures.

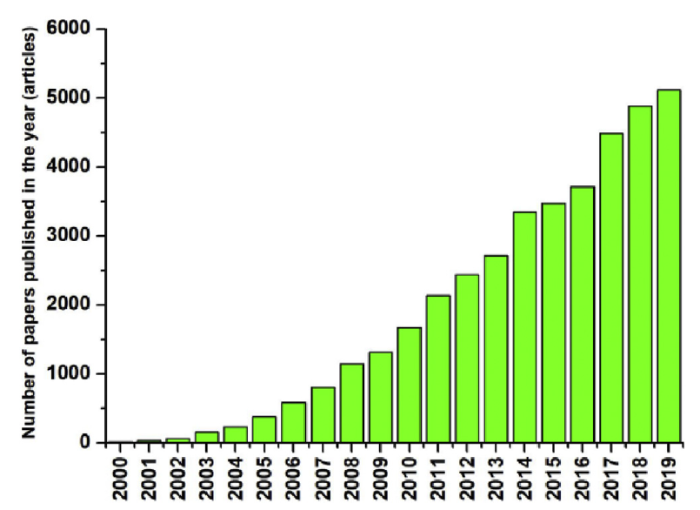

Since 2000 due to the growing interest in electrospun membranes, the number of articles published related to electrospinning has increased exponentially (Fig. 1). In the ranking of the total number of articles published by country, China ranks first, accounting for almost 50 % of the total number of papers published worldwide, followed by the United States and South Korea (Fig. 2). Thus, rendering China as the most active country in the field of electrospinning.

Fig. 1.

Fig. 1.

Graphical representation of the number of articles on electrospinning published worldwide for each year since 2000.

Fig. 2.

Fig. 2.

Proportion of electrospinning papers published by countries in the world.

2.2. Different electrospinning techniques

The traditional method of electrospinning and its equipment is illustrated in Fig. 3(A). In this method of electrospinning, a high voltage is applied to the polymer solution to create a Taylor cone at the tip of the nozzle, typically a blunt needle. Using a syringe pump to control the polymer solution flow rate, a jet erupts from the Taylor cone when the potential difference between the charged solution and collector overcomes the surface tension of the solution. The erupted liquid jet creates fibers that continue to travel towards the collector, causing the solvent to evaporate and resulting in the collection of dried nanofibers. Depending on the shape of the receiver, membranous or tubular nanofibrous structures can be fabricated, and the fiber alignment can be regulated (aligned to random) depending on the rotation speed of the receiver.

Fig. 3.

Fig. 3.

Schematic of different electrospinning techniques. (A) The traditional electrospinning; (B) Coaxial electrospinning; (C) Emulsion electrospinning; (D) Dynamic water flow electrospinning.

Similar to traditional electrospinning, coaxial electrospinning incorporates a coaxial nozzle, which contains two nozzles of different sizes with one forming a sleeve around the other (Fig. 3(B)). The nozzle with the smaller inner diameter transports the core solution, and the nozzle with the larger inner diameter transports the shell solution. In this way, the shell solution and the core solution, contained in separate reservoirs, are ejected simultaneously through the coaxial nozzle, and the core-shell nanofiber is created through the same mechanism as traditional electrospinning using a potential difference. An advantage of coaxial electrospinning is that only the shell solution must be spinnable, so some non-spinnable drugs, growth factors, and other functional additives can be incorporated into the core solution, and thus the electrospun biomaterial.

Like coaxial electrospinning, emulsion electrospinning creates core-shell structure nanofibers but uses polymer emulsions for the preparation. This process is advantageous because the emulsion can be spun by a single spinning nozzle to obtain the nanofiber with a multi-core structure or core-shell structure without using a coaxial nozzle (Fig. 3(C)). During this process, the emulsion droplets can be drawn out in the nanofibers to create a core-shell structure or can remain as droplets to create a multi-core structure. Again, non-spinnable drugs, growth factors, and other active substances can be dispersed in the polymer solution and electrospun with emulsion electrospinning.

Another type of electrospinning is dynamic water flow electrospinning where nanofibers are first collected on a water surface, twisted by a water vortex, and subsequently collected on a rotating collector, as shown in Fig. 3(D). In this method, an upper and a lower water basin are utilized. The upper water basin contains a small hole at the base from which water can flow by gravity, thereby forming a vortex on the water surface. Then, as the nanofibers are electrospun on the water surface, they flow through the vortex and are wound into yarn. The water and yarn flow from the upper basin to the lower water basin from where water is recycled by a pump to the upper one to continue the process. As the yarn flows to the lower basin, it is collected on a rotating receiver, which generates a porous nanoyarn scaffold. Compared to traditionally electrospun membranes, these materials have rougher surfaces, larger pore sizes, and higher porosities, suggesting that they may be more conducive to the 3D growth of cells when used as tissue engineering scaffolds. [24], [25]

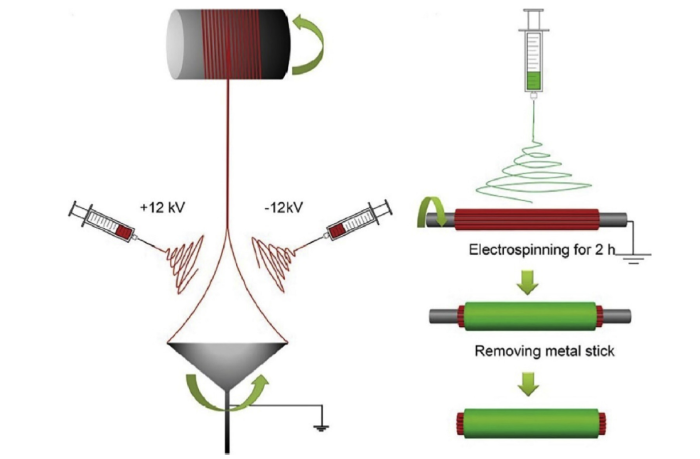

Another approach to creating nanoyarns utilizing a double-spray of electrospun nanofibers to prepare continuous nanoyarns is shown in Fig. 4(a) and (b). One spinning nozzle produces positively charged nanofibers through the application of a positive high voltage, and another spinning nozzle produces negatively charged nanofibers through the application of a negatively charged high voltage. This arrangement results in the winding together of oppositely charged fibers that are collected on a rotating funnel to form a coil (Fig. 4(c) and(d)), resulting in a nanoyarn (Fig. 4(e)) [22].

Fig. 4.

Fig. 4.

Diagram illustrating the double-spray electrospinning [22]. (a) The schematic of double-spray electrospinning. (b) A photograph of the receiving funnel. (c) A photograph of the process of nanoyarn formation and winding. (d) A photograph of yarn coil. (e) Scanning electron microscopy (SEM) images of a single nanoyarn.

3. Electrospun nanofibers as tissue engineering scaffolds

3.1. Ideal scaffold for tissue engineering

Tissue engineering scaffolds are designed to function as a temporary substitute for tissue defects that induce cell ingrowth and neotissue formation while degrading in vivo as the tissue matures. Electrospinning is a technology with tremendous potential for fabricating tissue engineering scaffolds because it fabricates biomimetic structures similar to the scale and morphology of the native ECM. In fact, the ECM of the human body is a nanofiber gel network composed of several structural proteins, such as collagens and elastin, interwoven with non-structural proteins, like glycosaminoglycans. The diameter of the ECM structural fibers is usually 50-300 nm, and the fibers provide anchoring points for cell attachment and maintain overall tissue/organ shape and form [26]. As shown in the SEM of an example tissue after freeze-drying (Fig. 5), the fibroblasts extend their processes in the direction of the collagen fibrils [27]. As the cell receptors bind to ligands on the ECM, outside-in signaling can induce changes in cell behavior, which creates a dynamic crosstalk between the cells and the ECM. Therefore, the tissue engineering scaffold should not only be biomimetic of the ECM structure but also of the signals contained within the ECM. Research has shown that the scale of the fibers is of utmost importance for inducing appropriate outside-in signaling with nanofibrous structures, significantly improving the function of tissue engineering scaffolds for bone, cartilage, cardiovascular, nerve, and bladder regeneration [28], [29].

Fig. 5.

Fig. 5.

SEM of fibroblasts in a native tissue after freeze-drying [27].

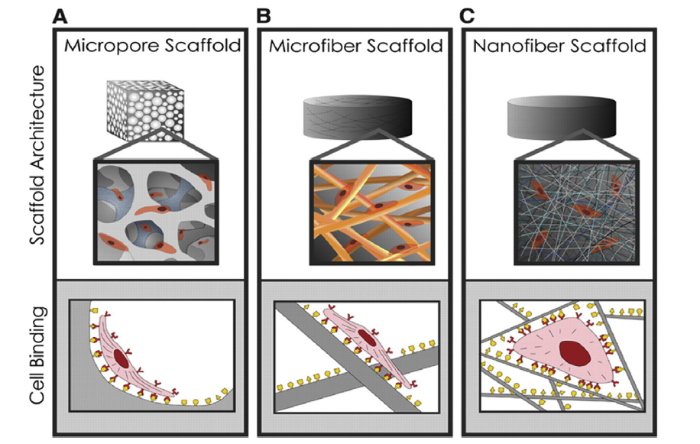

Several studies illustrate the regulatory effects of nanomaterials on cell behavior. For example, Pattison et al. [30] used nanoscale poly lactic-co-glycolic acid (PLGA) scaffolds and smooth muscle cells to create a tissue-engineered bladder in vitro and demonstrated that the cells adhered better, were more proliferative, and secreted more collagen and elastin on the nanoscale compared to microscale scaffolds. Similarly, carbon nanofibers have been shown to increase the proliferative capacity of osteoblasts and their secretion of alkaline phosphatase and calcium [31]. These changes in cell behavior are thought to be related to changes in cell morphology [32]. While adhering to a flat morphology on microporous and microfibrous scaffolds (Fig. 6(A, B)), cells exhibit stretching behavior, but when they adhere to the larger surface area of nanofibrous scaffolds the morphology was similar to that observed in native tissues (Fig. 6(C)). The high surface area of nanofiber scaffolds facilitates more significant protein adsorption and provides more adhesion sites for receptors on the cell membranes. As a result, nanofibrous scaffolds that have a similar structure to the ECM may induce more appropriate cell behavior through changes in cell morphology during attachment and migration, providing a microenvironment more conducive to guided tissue regeneration.

Fig. 6.

Fig. 6.

Schematic of how a scaffold structure affects cell adhesion and spreading [32]. (A), (B) Cells adhere in a flat morphology on the microporous and microfiber scaffolds, similar to that observed on flat surfaces. (C) Nanofibers have a greater surface area, and therefore adsorbed more protein, providing more adhesion sites for cell membrane receptors.

3.2. Advantages of electrospun nanofibers

Electrospun nanofibers are advantageous for fabricating tissue engineering scaffolds because the electrospinning process is versatile and tailorable for the specific tissue application. Most biocompatible synthetic and natural polymers can be electrospun into nanofibers independently or as blends of multiple polymers [33], [34]. The orientation of nanofibers can be controlled to guide cell attachment and orientation within the scaffolds, which is beneficial for tissues with an aligned ECM, such as tendons and ligaments [35]. Because of the recent advances in electrospinning technology, bioactive factors and functional drugs can also be encapsulated in the electrospun nanofibers through coaxial or emulsion electrospinning and released over time. Imparting bioactivity, in addition to the structural features of the scaffold, has enabled the creation of multiple tissue engineering scaffolds with tissue-specific functions.

4. Electrospun nanofibers for skin tissue regeneration

Skin is the largest organ of the body and provides an external barrier to protect against pathogen invasion [36]. As such, chronic, non-healing wounds that are often infected or large-scale traumatic injuries, such as those created by burns or automobile accidents, pose a significant threat to health due to the risk of systemic infection. Autologous skin grafts are commonly used to accelerate wound healing and recover the function of the damaged skin; however, they result in donor site morbidity and may not be available depending on the extent of tissue injury [37]. As an alternative, a tissue engineering scaffold could be used to guided healing and provide protection. Additional essential functions of the scaffold are to keep the wound and surrounding area moist, adsorb secretions, have good air permeability, and inhibit bacterial growth. Thus, the features of electrospun scaffolds are appealing for use in skin tissue regeneration applications.

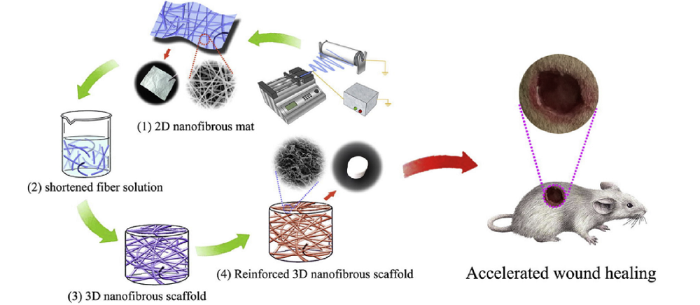

A wide variety of natural and synthetic polymers have been electrospun and investigated for use in skin tissue engineering. Chitosan blended with collagen or silk fibroin has been shown to support cell proliferation and accelerate wound healing compared to control gauze [38]. Similarly, an antimicrobial peptide blended with silk fibroin was used to create a composite electrospun nanofiber matrix that exhibited significant antibacterial activity against gram-positive bacteria and gram-negative bacteria and accelerated wound healing in an in vivo model [39]. Li et al. [40] used electrospinning to generate nanofibers made from tilapia skin, which is primarily composed of type I collagen, and demonstrated that the nanofiber membranes had good biocompatibility and low immunogenicity, suggesting that tilapia skin may be a good source for collagen used in skin tissue engineering. Focusing on creating a hemostatic biomaterial, Ma et al. [41] incorporated ligustrazine into a silk fibroin electrospun scaffold and found that it promoted wound hemostasis, was anti-inflammatory, possessing blood compatibility, and induced healing. To improve the mechanical properties of an electrospun biomaterial, bioactive glass has been incorporated into electrospun fish collagen nanofibers [42]. The composite material had greater tensile strength, antibacterial activity against Staphylococcus aureus, and promoted the adhesion and proliferation of human skin fibroblasts compared to pure, fish collagen control nanofibers. Xie et al. [43] created an electrospun scaffold with five O-quaternary ammonium chitosan, which has broad-spectrum antibacterial activity, and demonstrated that it had good blood compatibility and biocompatibility, inhibited the formation of biofilm, was hemostatic, and promoted wound healing. Lastly, Yu et al. [44] recently developed a four-step process including electrospinning, mechanical cutting/mincing, freeze-drying, and heat treating to fabricate a scaffold with enhanced porosity and adsorption properties (Fig. 7). The scaffold made from polycaprolactone-poly-ethylene glycol-polycaprolactone exhibited a unique, hierarchical porous structure with larger pores and high porosity, which resulted in a 3.3-fold increase in water absorption compared to a two-dimensional (2D) membrane. In addition, the scaffold improved the adhesion, proliferation, and migration of mouse fibroblasts compared to the 2D mats and resulted in a minimal inflammatory response, early re-epithelialization, and formation of granulation tissue in vivo. Together, these examples illustrate the diversity of scaffolds that can be fabricated by electrospinning for skin tissue engineering.

Fig. 7.

Fig. 7.

Schematic of the fabrication of a scaffold for skin tissue engineering by a four-step process and the animal experiment to evaluate wound repair [44]. (1) 2D nanofibrous mats were fabricated via electrospinning. (2) A homogeneous short fiber solution was prepared by high-speed mechanical cutting. (3) The 3D scaffold was obtained after freeze-drying the solution. (4) The 3D scaffold was reinforced through heat treatment.

In the future development of scaffolds for skin tissue engineering, additional bioactive components should be investigated, such as adding temperature or pH-sensitive materials to the dressing. Additives like these could provide biofeedback through color changes for real-time monitoring of wound healing and infection. This feedback could provide additional insight into the wound care plan and improve patient outcomes. Ultimately, the simplicity and versatility of the electrospinning process facilitates the development of these multifunctional, bioactive scaffolds of skin tissue engineering.

5. Electrospun nanofibers for blood vessel tissue regeneration

More than 1.4 million patients in the United States receive a vascular graft every year, which costs around $25 billion US dollars [45]. This extensive market has a largely unmet need for small-diameter (i.e. inner diameter less than 5 mm) vascular grafts that can be used for tissue engineering. Currently available, non-resorbable small-diameter vascular grafts fail by thrombosis and neointimal hyperplasia at the anastomosis due to the reduced velocity of blood flow and lack of endothelization, ultimately resulting in stenosis and occlusion of the lumen [46]. Therefore, many tissue engineers are developing electrospun, resorbable small-diameter vascular grafts to guide blood vessel regeneration and circumvent the problems associated with current, synthetic grafts.

Several groups have explored the use of heparin and vascular endothelial growth factor (VEGF) to reduce thrombosis and improve endothelialization. Huang et al. [47] prepared an electrospun poly (L-lactic acid-co-caprolactone) (P(LLA-CL) tubular graft containing heparin by coaxial electrostatic spinning. When implanted in the femoral artery of a dog, the heparin functioned as an anticoagulant and improved patency. In order to promote the proliferation of endothelial progenitor cells, Chen et al. [48] loaded VEGF into the heparin-containing scaffold by emulsion electrospinning. The controlled release of heparin and VEGF from vascular grafts showed good anticoagulation and promoted endothelial progenitor cell proliferation. These examples illustrate the ability to fabricate electrospun vascular grafts with anticoagulant properties that encourage neointimal regeneration.

To further increase the biocompatibility of vascular grafts, natural polymers have been incorporated into the electrospun scaffolds. In one example, Yin et al. [49] blended collagen and chitosan with P(LLA-CL). Incorporating collagen and chitosan significantly increased endothelial cell proliferation and spreading compared to the P(LLA-CL) control, suggesting an improvement in biocompatibility. Similar work by Wu et al. [50] optimized the blend of collagen and chitosan with P(LLA-CL) and found that the weight ratio of 3:1 was optimal for mechanical integrity, biodegradability, and in vitro cellular compatibility (Fig. 8). When used in a canine femoral artery model, the graft demonstrated excellent structural integrity, higher patency rates, better endothelial and smooth muscle cell growth, and higher expression of angiogenesis-related genes and proteins compared to P(LLA-CL) control grafts without the natural polymers. These examples illustrate that the addition of natural polymers, such as collagen and chitosan, can improve biocompatibility and vascular remodeling for blood vessel tissue engineering.

Fig. 8.

Fig. 8.

Confocal microscopy images of human smooth muscle cells (hSMCs) and L929 murine fibroblasts after culturing for 5 days on the P(LLA-CL), 3: 1 and 1:1 composite scaffolds (A). Cell viability of hSMCs (B) and L929 cells (C) cultured for 1, 3, and 5 days [50].

In another approach, Kuang et al. [51] prepared the inner layer of an electrospun vascular graft by coaxial electrospinning with a core containing heparin and a shell containing salvianolic acid B (SAB) loaded in mesoporous silica nanoparticles (MSN) (Fig. 9). The release of heparin and SAB was sustained for almost 30 days, and synergistically promoted human umbilical vein endothelial cell (HUVEC) growth and blood compatibility. With an emphasis on regulating smooth muscle cell arrangement and infiltration, Wu et al. [52] used dynamic liquid electrospinning to prepare nanoyarns and conjugate electrospinning to prepare conjugated nanoyarns from 75 % P(LLA-CL) and 25 % collagen. The dynamic nanoyarns regulated smooth muscle cell infiltration while the conjugate nanoyarns guided the directional growth of the cells, suggesting that both scaffolds may be advantageous for guiding the regeneration of tunica media.

Fig. 9.

Fig. 9.

Process of fabricating the core (heparin)-shell (PC/SAB-MSN) fiber (left) [51]. Transmission electron microscope images of MSN (A) and core (heparin)-sheath (P(LLA-CL) and collagen with SAB-MSN) fiber (B), SEM of the nanofiber with MSN particle on the surface (C), SEM-EDS image of the fiber membrane (D).

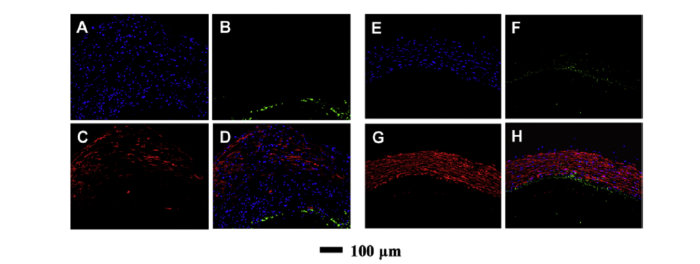

Because controlling the regeneration of the neointima, important for anticoagulation, and the tunica media, important for mechanical integrity, requires independent cues, several groups have developed multi-layered electrospun vascular grafts with each layer serving a different function. Wu et al. [53] designed and fabricated a bi-layered vascular scaff ;old with a dense nanofiber inner layer to avoid transmural blood leakage and a loose nanoyarn outer layer to guide smooth muscle cell ingrowth. Likewise, heparin and CD133 antibodies, to encourage endothelial cell adherence, were incorporated into an inner layer of an electrospun scaffold by coaxial electrospinning, which was then covered by an outer layer of nanoyarns generated by dynamic liquid electrospinning. The resulting bi-layer graft had compliance comparable to that of the human saphenous vein and was improved relative to the commercially available expanded-polytetrafluoroethylene grafts. Moreover, the sustained release of heparin and CD133 over a period of approximately 40 days encouraged the regeneration of an endothelial cell monolayer and infiltration of smooth muscle cells when implanted in the abdominal aorta of a rat for 2 months (Fig. 10). Wu et al. [54] has also developed a three-layer electrospun vascular graft through a three-part electrospinning process using blends of P(LLA-CL), PLGA, collagen, and silk fibroin. The inner layer contains P(LLA-CL) and collagen in axially aligned nanofibers, the middle layer is composed of PLGA and silk fibroin nanoyarns aligned circumferentially, and the outer layer is made from randomly deposited P(LLA-CL) and collagen nanofibers to support the composite structure. The mechanical properties were found to be suitable for use as a vascular graft, and fluorescent staining of endothelial cells and smooth muscle cells illustrated that the inner and middle layers regulated cell morphology in the lumen and tunica media, respectively. Moreover, the in vivo results showed that the three-layered vascular graft supported cell infiltration, scaffold biodegradation, and abundant collagen production after subcutaneous implantation for 10 weeks. Together, these studies suggest that a multi-layered scaffold to mimic the anatomy and physiology of native blood vessels may improve the performance of small-diameter grafts for vascular tissue regeneration.

Fig. 10.

Fig. 10.

Fluorescence micrographs of (A-D) the bilayer vascular scaffold after implantation for 2 months and (E-H) the autologous vessel both after immunohistochemical staining of (A, E) DAPI for nuclei, (B, F) CD31 for endothelial cells, and (C, G) α-SMA for smooth muscle cells. (D, H) The corresponding merged fluorescence micrographs [53].

6. Electrospun nanofibers for nerve tissue regeneration

Peripheral nerve injury can lead to sensory, motor, or autonomic problems in patients. The capacity of the peripheral nerves to regenerate is profound compared to the central nervous system. If the defect is less than 5 mm, the nerves can repair themselves, illustrating that there are endogenous mechanisms to regeneration the nerve and restore function. Unfortunately, when the length of the nerve defect is greater than 5 mm, the self-repair process is limited, and a biomaterial is needed to secure both ends of the injured nerve to guide regeneration. In recent years, electrospinning has been investigated to create neural scaffolds, and the resulting materials have evolved from simple, hollow tubes into more complex structures, known as nerve guidance conduits (NGC) [55]. NGCs can contain internal filaments, sponge fillers, and physical and chemical cues to mimic the structure and bioactivity of nerve bundles (Fig. 11) [56]. The following sections will discuss several types of NGC developed via electrospinning.

Fig. 11.

Fig. 11.

A schematic showing how ideal NGCs are constructed by incorporating a diverse array of physical and biological cues into a neural scaffold with different configurations [56].

6.1. Simple hollow luminal structure NGC

Simple hollow NGC provides a lumen for the regenerating nerve to grow while limiting surrounding tissue ingrowth, and the material selection influences the potential for regeneration. Blends of silk fibroin and P(LLA-CL) have been shown to be biocompatible and enhance cell proliferation compared to P(LLA-CL) controls [57]. Based on these findings, Wang et al. [58] prepared silk fibroin and P(LLA-CL) blended nanofiber scaffolds with aligned fibers and created a NGC by wrapping the electrospun scaffold around a stainless steel rod. The NGC was implanted into a 10- mm sciatic nerve defect in rats to evaluate nerve regeneration. The results demonstrated that the NGC improved regeneration, resulting in a nerve with a more mature structure containing thicker nerve fibers at a higher density, and function when compared to the P(LLA-CL) control. These findings highlight the impact of the polymer selection on the potential for nerve regeneration and suggest that silk fibroin enhances nerve regeneration

6.2. Growth factor incorporated into NGC

Nerve growth factor (NGF) promotes the development, growth, differentiation, and maturation of central and peripheral neurons, plays a role in the maintenance of normal nerve function, and accelerates the repair of nervous system injuries. Thus, the incorporation of NGF into aligned, electrospun fibers by coaxial electrospinning to enhance nerve regeneration has been investigated [59]. In this study, NGF was released slowly from the electrospun scaffold and retained activity over 60 days, which is important for the long-term regenerative outcome. Additionally, the NGF containing scaffold had enhanced performance compared to the control after a 12-week in vivo study. These data indicate that the bioactivity of NGF and the structural guidance from the aligned scaffold work in tandem to more effectively promote nerve regeneration. Similarly, Wang et al. [60] investigated the use of NGF in the core of PLGA shell fibers, which were collected in an aligned orientation, wrapped on a stainless steel rod, and sealed with a nylon filament to form the NGC. After 12 weeks in a 13-mm sciatic nerve defect in rats, the scaffold stimulated nerve regeneration, and electrophysiology and muscle weight tests showed that the functional recovery of the regenerated nerve was significantly improved, relative to the non-growth factor containing control. These studies suggest that NGF plays a critical role in promoting the repair of injured peripheral nerves.

6.3. Conductive nanofiber NGC and electrical stimulation for nerve regeneration

Conductive materials, such as polyaniline and graphene, can be incorporated into electrospun nanofibers to create conductive NGC that transmit electrical signals from the fibers to the neurons to promote neuronal migration, proliferation, and differentiation. In one example, Zhang et al. [61] prepared the composite fiber scaffold containing polyaniline for conduction and NGF by coaxial electrospinning and evaluated the synergistic effect of electrical stimulation and NGF on the potential for regeneration. The authors found that electrical stimulation combined with NGF promoted Schwann cell proliferation and the growth of long axonal extensions from pheochromocytoma cells, which suggests that the combined effects are beneficial for nerve regeneration. In another example, Sun et al. [62] used conductive polypyrrole to coat an electrospun scaffold by in situ oxidative polymerization. The polypyrrole coating not only imparted electrical conductivity, but also increased the hydrophilicity of the scaffold, which together had additive effects and resulted in higher rates of Schwann cell proliferation compared to control scaffolds. Similarly, the polypyrrole coating, in combination with electrical stimulation, was shown to induce pheochromocytoma cell differentiation and enhance axonal growth. These results indicate the promising potential of conductive polypyrrole-coated nanofibrous membranes for peripheral nerve repair and regeneration.

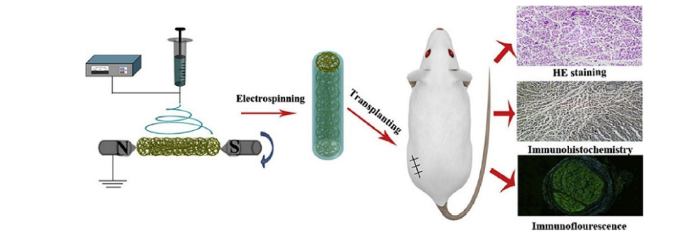

Graphene oxide has also been used as a coating to create conductive, electrospun NGC (Fig. 12) [63]. As shown by in vitro studies, the graphene oxide-coated scaffolds have enhanced the migration, proliferation, and myelin formation of Schwann cells and up-regulate the expression of focal adhesion kinase in pheochromocytoma cells, suggesting the scaffolds promote neurite outgrowth. Furthermore, when implanted in a 10-mm sciatic nerve defect in vivo, the NGC facilitated repair and regeneration, similar to that of autologous transplantation. In an additional study, Wang et al. [64] coated an electrospun scaffold with reduced graphene oxide and found similar results both in vitro and in vivo. Together, these results suggest that the conductive scaffolds positively impact the potential for peripheral nerve regeneration by providing electrical stimulation to the regenerating neurons.

Fig. 12.

Fig. 12.

Schematic of the graphene oxide-coated antheraea pernyi silk fibroin (ApF)/P(LLA-CL) scaffold preparation [63].

6.4. Filaments-containing NGC

To guide the migration and proliferation of nerve cells, NGCs have been fabricated containing filaments that function as cell highways. In one case, Li et al. [65] prepared poly (L-lactic acid) (PLLA) nanoyarns by a dual spinneret system and used them to fill the lumen of a P(LLA-CL) electrospun NGC (Fig. 13). In a series of in vitro experiments, Schwann cells demonstrated increased cell proliferation and enhanced elongation on the nanoyarns compared to PLLA-film, and further, migrate through the yarn structure with axons extended along the axes of the yarn. Similarly, Wu et al. [66] prepared a nanoyarn-filled NGC from electrospun PLGA and included a laminin coating to enhance cell adhesion. In vitro experiments showed that the laminin coating enhanced both Schwann cell proliferation and migration to compared to non-coated controls, demonstrating the importance of biological signals in addition to topographical features for regulating and enhancing peripheral nerve regeneration. In another study, polypyrrole was coated on electrospun polycaprolactone (PCL) nanoyarn filaments to create a conductive, filament-filled NGC (Fig. 14) [67]. Like the other examples, the coating enhanced Schwann cell proliferation, suggesting that conductive filaments may be beneficial for guiding peripheral nerve repair.

Fig. 13.

Fig. 13.

Mechanism of nanofiber yarn fabrication and schematic of incorporating the nanofiber yarn into the NGC [65].

Fig. 14.

Fig. 14.

Schematic of polypyrrole (Ppy)-coated PCL nanoyarn (NY) fabrication for the development of a conductive, filament-filled NGC [67].

6.5. Sponge-containing NGC

Like the filament-filled scaffolds, NGC filled with 3D sponges are more conducive to cell migration and axonal regeneration and encourage the distribution of axons within the lumen of the scaffolds. This has been demonstrated by Sun et al. [68] through the preparation of an electrospun NGC filled with a nanofiber sponge, containing large pores and high porosity (Fig. 15). When implanted into a 10-mm sciatic nerve defect in rats, the sponge of the NGC was infiltrated with Schwann cells and appeared similar to the internal structure of a nerve bundle as determined by histological analysis. Compared to a hollow NGC, the sponge-filled scaffold significantly improved functional nerve repair and performed similarly to an autograft control as indicated by gait analysis and muscle weight. This study suggests that sponge-containing NGCs have significant therapeutic potential for applications in peripheral nerve repair.

Fig. 15.

Fig. 15.

Schematic illustrating the fabrication of the electrospun 3D nanofiber sponges and the fabrication of a NGC by electrospinning [68].

7. Electrospun nanofibers for bone tissue regeneration

Due to the high incidence of bone defects, which are caused by bone infections, bone tumors, and bone loss by trauma, there is a tremendous clinical demand for bone grafts [69]. Autologous bone transplantation is considered the clinical “gold standard” for the repair of critical-sized bone defects due to its remarkable osteoinductivity and osteoconductivity without adverse immunoreactions [70]. However, both autologous bone and allogeneic bone use are limited clinically by their availability. Therefore, using tissue engineering to regenerate bone is a promising method to overcome the disadvantage of insufficient donors [71], [72].

A scaffold for bone tissue engineering should be biocompatible, biodegradable, bioactive, and have sufficient mechanical properties for the bone environment. To satisfy these requirements, nanofiber scaffolds based on composite materials, such as organic and inorganic hybrid nanofibers, and loaded with functional factors, such as bone morphogenetic proteins (BMP), transforming growth factor-β3 (TGF-β3), VEGF, and silver nanoparticles, have become the focus of current research [73]. Using electrospinning to create these scaffolds is advantageous because the nanofibers are biomimetic of the ECM in natural bone, which consists mainly of hierarchically organized, mineralized collagen fibers [74], [75]. For example, Ye et al. [76] created a composite scaffold containing nano-hydroxyapatite, the main mineral component of bone, from electrospun scaffolds that were minced into small fibers, freeze-dried, and thermally crosslinked to create a 3D bone-like scaffold. Synthetic BMP-2-derived peptides were then immobilized on the surface, and the scaffold was evaluated in vitro and in vivo in a rat cranial bone defect model (Fig. 16). The results of the experiments demonstrated that the presence of nano-hydroxyapatite and the BMP-2 increased gene expression related to the osteogenic differentiation of stem cells and that BMP-2 peptide release was maintained for 21 days. Compared to controls, the scaffolds had better osteoinductive activity, promoted the expression of type Ⅰ collagen and osteogenic markers, such as Runt-related transcription factor 2 and osteocalcin, and increased alkaline phosphatase activity, resulting in new bone growth in the center of the defect, which was absent in controls.

Fig. 16.

Fig. 16.

Schematic of 3D nanofibrous scaffold preparation incorporating nano-hydroxyapatite (nHA) and BMP-2 for testing in an in vivo, cranial defect regeneration model [76].

In an attempt to regulate the bone remodeling processes, Wang et al. [77] designed an electrospun scaffold for the dual delivery of MSNs, shown to accelerate bone formation, and alendronate, shown to suppress bone resorption (Fig. 17). This scaffold was found to reduce the bone healing time from 12 weeks to nearly 4 weeks based on bone maturity scores and vascularization, as indicated by CD31 staining. As healing continued to 12 weeks, the bone maturity scores for the scaffold were nearly double the control scaffolds without MSN and alendronate, and the scaffolds were significantly more vascularized. These results indicate that electrospun nanofibers loaded with silicate and alendronate modulate the bone remodeling process and facilitate robust vascularization, which is vital for adequate nutrient supply during bone regeneration.

Fig. 17.

Fig. 17.

Design of an scaffold containing MSN and alendronate (ALN) for the dual delivery of ALN and silicate to modulate bone resorption and formation for accelerating bone repair. The ALN pre-loaded within the MSNs is released from the nanofibers and inhibits the bone-resorption process by preventing GTP-related protein expression. The silicate produced by the hydrolysis of MSNs is released from the nanofibers and promotes the bone-forming process by improving vascularization and bone calcification [77].

To promote cell adhesion, Gutiérrez-Sánchez et al. [78] used electrospinning to prepare poly (lactic acid) (PLA) nanofibers containing starch and adsorbed arginine-glycine-aspartic acid (RGD) peptides to the surface. The scaffolds modified with RGD had better cell adhesion compared to controls, which shows potential for guided bone regeneration. To mimic the mineral composition of bone, hydroxyapatite has been incorporated into electrospun silk fibroin scaffolds through a two-stage process (Fig. 18) [79]. First, hydroxyapatite was included in the electrospinning solution to localize the particles within the fibers. Then, the surface of the fibers was modified with mussel adhesive-inspired polydopamine chemistry and deposited with hydroxyapatite, creating the second layer of particles. This two-stage functionalization was shown to improve the osteogenesis of human adipose-derived mesenchymal stem cells transfected with the transcriptional coactivator with PDZ-binding motif both in vitro and in vivo, demonstrating the potential use of these scaffold with stem cells for enhanced bone formation. Similarly, Natália Hadler Marins et al. [80] prepared a composite scaffold with hydroxyapatite and niobium pentoxide (Nb2O5) particles, which has been used as a bioactive component on metallic implants. These scaffolds were found to be non-cytotixc and promoted cell proliferation and cell adhesion, suggesting a potential use for this novel mineral additive in bone tissue engineering. Ultimately, electrospun biomaterials have attracted more and more attention in bone tissue engineering in recent years, and designing such to support osteoinduction and vascularization should enhance their performance in bone tissue engineering.

Fig. 18.

Fig. 18.

Electrospun silk fibroin nanofibrous scaffolds engineered with two-stage hydroxyapatite (HA) particle functionalization. These scaffolds were found to support the osteogenic differentiation of genetically-modified human adipose-derived mesenchymal stem cells after 21 days in vitro and enhance mineralized bone formation and collagen deposition in vivo in a critical-sized calvarial bone defect after 8 weeks [79].

8. Electrospun nanofibers for cartilage tissue regeneration

Damage to the articular cartilage, through sports-related injuries, trauma, and aging can lead to osteoarthritis and debilitating pain in the joints, eventually necessitating total joint replacements [81]. Although autografts can be used to treat minor damage, the availability of grafts is limited, and their implantation can lead to an adverse immune response. Furthermore, autografts are not efficacious for treating severe cartilage defects. Therefore, using a tissue engineering approach with electrospun scaffolds is a promising strategy for the treatment of minor and severe cartilage defects to reduce the occurrence of osteoarthritis and total joint replacements [82]. Because electrospun nanofiber scaffolds contain densely packed fibers with small pores, a current focus in cartilage tissue engineering is developing methods to process the pseudo-2D electrospun scaffolds into more 3D structures that are suitable for cartilage repair and mimicking of the native ECM.

Recently, Chen et al. [83] developed a thermally-crosslinked scaffold from a freeze-dried structure composed of short fibers derived from a nanofiber membrane (Fig. 19). The scaffold ontained was functionalized with hyaluronic acid, the protein that gives articular cartilage its lubricating and shock-absorbing properties, and evaluated in vitro and in vivo for its ability to stimulate cartilage regeneration. The resultant scaffold possessed high water adsorption and good mechanical and compressive strength. In the in vitro experiments, chondrocytes were found to adhere to the surface of the scaffold and proliferate along the nanofibers. Moreover, when implanted into an articular cartilage defect in vivo for 12 weeks, the scaffold was found to promote improved repair relative to the non-treated defect as well as a scaffold that was not functionalized with hyaluronic acid. These data indicate that the 3D scaffold generated from an electrospun membrane and functionalized with hyaluronic acid may have therapeutic potential.

Fig. 19.

Fig. 19.

Macroscopic images (a, d, and g) of the cartilage joints from the non-treated group, group treated with the non-functionalized scaffold (3DS-1), and the group treated with the hyaluronic acid-functionalized scaffold (3DS-2) at 12 weeks after surgery. Histological analysis of the cartilage defect area from the three groups, stained with Safranin O-fast green (b, e, and h) and H&E (c, f, and i), indicate that the functionalized scaffold enhanced repair. Arrows and dotted lines indicated the defect sites. OC: original cartilage tissue. RC: repaired cartilage tissue [83].

In addition to articular cartilage, regeneration of hyaline cartilage for the treatment of congenital defects, trauma, or disease is being investigated. Because hyaline cartilage has unique morphologies, such as in the ears and nose, combining electrospinning with 3D printing enables the construction of detailed shapes that may be beneficial for hyaline cartilage regeneration. For example, Chen et al. [84] developed an ink for 3D printing composed of electrospun PLGA/gelatin nanofibers from a minced membrane in a hyaluronic acid and polyethylene oxide (PEO) solution (Fig. 20). The hydrophilic scaffold was found to have large, regular pores between the fibers, high porosity, absorbed large volumes of water, and possessed water-induced shape memory (Fig. 21). The rapid recovery of shape, within 30 s, suggests that this 3D printable scaffold could be used to guide the regeneration of complex cartilage structures in vivo.

Fig. 20.

Fig. 20.

Schematic of various electrospun fiber scaffolds [84]. (a) Traditional fiber scaffold-electrospun fiber membrane. (b) 3D fibrous scaffold constructed by dispersed Electrospun, short fibers via freeze-shaping. (c) The synthetic steps of a 3D-printed fiber-based scaffold.

Fig. 21.

Fig. 21.

Water-induced shape memory of 3D printed scaffolds made from an ink containing electrospun nanofibers [84]. (a) Square scaffold. (b) In a wet state, a tubular-shaped scaffold was obtained by folding the opposite angle of the square, and the scaffold was freeze-dried to maintain its deformed shape. (c) Shape recovery process of square scaffold after absorption of water for 12 s. (d) Square scaffold completely recovered its original shape within 20 s of water absorption. (e) Rectangular scaffold. (f) Wet scaffold was folded into a wave shape and freeze-dried to maintain its shape. (g) Shape recovery process of rectangular scaffold after water absorption for 12 s. (h) Rectangular scaffold completely recovered its original shape within 30 s of water absorption.

In another study, Zhang et al. [82] created a bi-layered scaffold with a layer of electrospun PLA nanofibers and a layer of compressed, type I collagen for repairing an osteochondral defect (Fig. 22). Compared to a control scaffold of collagen alone, the bi-layer scaffold was found to promote osteogenic differentiation in vitro and induce rapid subchondral bone formation in vivo in a rabbit model of an osteochondral defect (Fig. 23).

Fig. 22.

Fig. 22.

Fabrication and characterization of collagen control scaffolds and bi-layered scaffolds of electrospun PLA and collagen [82]. The fabrication process of collagen scaffolds (A) and bi-layered scaffolds (B) and their microstructures.

Fig. 23.

Fig. 23.

Macroscopic images of the cartilage joints from three groups at 6 (upper panel) and 12 (lower panel) weeks after surgery [82]. (A, D) Non-treated group, (B, E) collagen control group, and (C, F) bi-layered scaffold group.

Like the ears and nose, the cartilage of the trachea has a unique shape and is in close proximity to additional tissues, such as muscle, mucous membranes, and other connective tissues. When formed into a tubular structure, an electrospun tissue engineering scaffold could be used to guide tracheal cartilage regeneration. For example, one group created a scaffold by coaxial electrospinning with a P(LLA-CL) and collagen shell and kartogenin solution as the core fluid [85]. Kartogenin, which induces chondrogenesis in mesenchymal stem cells, was released over a period of two months from the nanofibers and shown to induce the proliferation and chondrogenic differentiation of rabbit bone-marrow derived mesenchymal stem cells by morphological analysis and PCR. These results suggest that the core-shell nanofibrous scaffold could be an effective delivery system for kartogenin and could be used as a tissue engineered scaffold for tracheal cartilage regeneration. Using the same shell, Wang et al. [86] substituted bovine serum albumin plus recombinant TGF-β3 into the core to create another core-shell nanofiber scaffold. The TGF-β3 was released over a two-month period and was shown to be bioactive as determined by type II collagen and glycosaminoglycan production by chondrocytes. Additionally, the proliferation, morphological analyses, and differentiation of mesenchymal stems cells derived from Wharton's jelly and seeded on the scaffolds indicated that the scaffold was biocompatible and promoted chondrogenic differentiation. These data suggest that the TGF-β3 releasing scaffold in combination with mesenchymal stem cells could be used in the construction of tissue-engineered tracheal cartilage.

9. Electrospun nanofibers for tendon/ligament tissue regeneration

9.1. Electrospun nanofibers for tendon tissue regeneration

Tendon and ligament injuries include inflammation, tears, and ruptures that result in severe pain and account for roughly 50 million related surgeries annually around the world [87], [88]. Currently, standard surgical treatments use autografts, allografts, or artificial prostheses. Although considered the “gold standard” because of their good remodeling and lack of immune response, autografts are limited by donor site availability and lead to extended operating times and donor site morbidity [89]. Alternatively, allografts can be used, but allogenic materials are associated with a risk of disease transmission, immune rejection, and high re-rupture rates due to mismatches of gender, age, and body weight between donors and recipients. To deal with these shortcomings, tissue engineering scaffolds based on electrospun fibers provide a possible alternative for the treatment and regeneration of damaged tendons and ligaments.

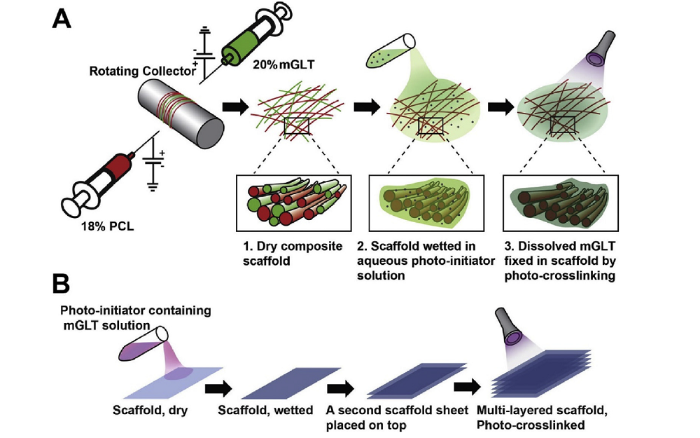

The major challenge in tendon tissue engineering is the low self-regenerative capacity associated with the hierarchically organized, dense collagen ECM. Uniaxially aligned nanofibers can be used to mimic the organization of collagen fibers in tendons and can be incorporated with biochemical features to stimulate tissue regeneration. For example, Yang et al. [90] developed a novel, multilayer composite scaffold composed of fibrous PCL and methacrylated gelatin, interspersed by dual-electrospinning, and incorporated human-adipose derived stem cells (Fig. 24(A)). The scaffold was composed of five sheets that were crosslinked together and reinforced with a methacrylated gelatin layer carrying the stem cells (Fig. 24(B)). The stem cells were treated with TGF-β3 for 7 days to promote differentiation into tenocytes, and real-time PCR showed pronounced up-regulation of tendon markers scleraxis and tenascin-C, indicating that the encapsulated cells remained responsive to soluble tenogenic factors, and that the constructs were porous enough for the diffusion of exogenous biochemical cues. This novel cell-scaffold construct combines the mechanical advantages of PCL nanofibrous scaffolds and gelatin to mimic the mechanical features and structure of tendons while promoting the native tendon cell phenotype. Likewise, Rinoldi et al. [91] fabricated an electrospun nanocomposite system for tendon tissue engineering. The authors created a bead-on-string fibrous structure and incorporated silica particles to improve the biological activity of the constructs and modify their topography, wettability, stiffness, and degradation rate. The results from their studies also indicate that the bead-on-string fibrous nonwoven composite scaffold is an attractive candidate that may be suitable for guided tendon regeneration.

Fig. 24.

Fig. 24.

(A) Composite scaffold preparation. Dual electrospinning was employed to fabricate a scaffold containing PCL and methacrylated gelatin (mGLT) fibers (Insert 1). The dry scaffold was wetted with an aqueous photo-initiator solution (Insert 2) and then photo-crosslinked by visible light to retain the gelatin (Insert 3). (B) Scaffold sheets were wetted, stacked, and exposed to visible light for crosslink formation between adjacent scaffold layers to create a complex multi-layered structure [90].

Several groups have been working on improving the three-dimensionality of electrospun scaffolds for tendon and ligament engineering by creating new processing methods for enhanced porosity. Laranjeira et al. [92] proposed the production of continuous aligned nanofiber threads from blends of PCL, chitosan, and cellulose nanocrystals and explored their assembly into 3D scaffolds using different textile techniques (Fig. 25). The authors demonstrated that the dimensions of the scaffold could be tailored through varying the braiding technique and manipulated to produce structures that matched the specific sizes of tendon or ligament defects. In addition, the scaffolds were found to have stress-strain curves that mimicked the characteristic nonlinear deformation behavior of tendons and ligaments without the typical plastic deformation observed in tendons and ligaments at high strain. Also, the scaffolds were shown to up-regulate the deposition of ECM from human adipose-derived stem cells in vitro and promote the differentiation towards a tenogenic-like phenotype. Given the morphological similarities, excellent mechanical properties, and the ability to promote differentiation, the 3D woven scaffolds have potential for tendon and ligament tissue engineering.

Fig. 25.

Fig. 25.

Schematic representation of electrospinning setup and hierarchical assembling of continuous aligned nanofiber threads (CANT). (A) Continuous electrospinning system to produce CANT; (B) CANT as the elementary unit of the 3D assembly, mimicking the collagen fibers in native tendon; (C) Yarns composed of twisted CANT represent tendon fascicles: i) Yarn 6, ii) Yarn 9, and iii) Yarn 12; (D) Braided 3D scaffold produced using Yarns; (E) Weaving process using Yarns: (i) arrays of 1 mm pins, (ii) Yarns weaving, and (iii) final 3D Woven scaffold. Both textile scaffolds represent the tendon unit [92].

In another study, Zhang et al. [93] created an electrospun scaffold with aligned PLLA fibers and trichostatin A, a histone deacetylase inhibitor, and evaluated the role of the inhibitor in tenocyte differentiation. Trichostatin A was shown to significantly up-regulate the expression of tendon markers compared to controls without the signaling molecule or scaffolds composed of random fibers, suggesting that the topographical cues of the aligned fibers in combination with trichostatin A could be used to promote teno-lineage differentiation and tendon defect repair.

In a recent study, researchers used electrospinning to build hierarchical, multiscale assemblies to mimic the hierarchical structure of tendons and ligaments [94]. To fabricate the scaffold, several fascicle-inspired PLLA bundles, composed of nanofibers, were grouped together by an electrospun PLLA sheath to mimic the epitenon ligament membrane. The hierarchical scaffold had a similar stiffness to a natural tendon and exhibited similar deformation to tendons and ligaments. These data indicate that the multiscale features of the electrospun scaffold were beneficial in creating the mechanical properties needed for a tendon or ligament scaffold.

9.2. Electrospun nanofibers for tendon-to-bone interface tissue regeneration

Engineering the tendon-to-bone interface (enthesis) is exceptionally challenging because it is a complex gradient of multiple tissues with unique compositions and cells that further requires the mechanical strength to avoid repair site elongation or rupture. Current anchor sutures that are used for tendon-to-bone repairs create stress concentrations that limit attachment strength, suggesting the need for a tissue-engineered solution [95]. Madhurakkat et al. [96] created an electrospun scaffold for the tendon-to-bone interface and immobilized platelet-derived growth factor-BB (PDGF-BB) on its aligned fibers in a gradient to promote the tenogenic differentiation of adipose-derived stem cells (Fig. 26). Their results suggest that the PDGF-BB gradient on the aligned nanofibers acted synergistically with topographical cues to spatially control cell differentiation, leading to high cytoskeleton elongation and anisotropic organization resembling the tendon-bone insertion site. Moreover, the scaffold increased the expression of tenogenic markers, such as type I and III collagen, tenascin-C, and scleraxis over a 14-day period. These data suggest the PDGF-BB gradient on aligned nanofibers may be useful for engineering the bone-tendon interface.

Fig. 26.

Fig. 26.

Schematic showing the structure of a native bone-tendon insertion site and fabrication of an aligned gradient platform with immobilized PDGF-BB that could mimic the bone-tendon insertion site [96].

In another approach, Li et al. [97] developed a double-layer scaffold with a PLLA layer and PLLA layer loaded with nanohydroxyapatite, mimicking the non-mineralized fibrocartilage and mineralized fibrocartilage at the enthesis (Fig. 27). In an in vivo study, the scaffold was found to significantly increase glycosaminoglycan staining at the tendon-bone interface and improve collagen organization when compared to a single layer of an electrospun PLLA control. These data indicate that the double-layer scaffold provides spatial control for the repair of mineralized and non-mineralized tissue at the tendon-bone interface, which may be beneficial for tissue engineering.

Fig. 27.

Fig. 27.

Schematic illustration of the application of the double-layer membrane. (a and b) The nanofibrous membrane is placed at the site of tendon-to-bone insertion. (c) The structure and composition of the scaffold mimic the normal fibrocartilage enthesis. (d) Illustration of hydroxyapatite (HA) growth on PLLA fibers [97].

10. Commercialization

Electrospinning nanofibers for biomedical applications is not just research and publications, it has real current and potential commercialization. For example, Guangzhou Medprin Regenerative Medical Technologies Co., Ltd developed a PLA nanofiber Dura product to regenerate the human dura after. njury, The Dura product has received European CE mark clearance and China Food and Drug Administration (CFDA) certificate many years before. Shanghai Songli Biotechnology Co. Ltd developed a fibrinogen/PLCL nanofiber Hernia Patch product for hernia treatment, and received the CFDA certificate in 2018. Shangdong Hanfang Pharmaceutical Co. Ltd developed a silk fibroin/PLCL nanofiber membrane for use as a wound dressing and also received the CFDA certificate in 2019. While there have been some commercial successes, there are still many biomedical companies on the way to develop nanofiber scaffolds for other biomedical application, thus in time we will see more commercialized, nanofiber medical products in the near future.

11. Conclusion

Electrospinning provides a simple and highly tailorable platform for the fabrication of ECM-mimicking tissue engineering scaffolds. Over the last several decades, progress in the field has resulted in new variations of the electrospinning process, including coaxial, emulsion, and dynamic liquid electrospinning, enabling the inclusion of bioactive agents and signaling molecules. Moreover, electrospinning can be combined with other processes, such as freeze-drying and 3D printing, to create nanofibrous scaffolds with complex 3D features. A wide variety of materials, including natural polymers, synthetic polymers, and their blends, have been used to fabricate nanofibrous, electrospun scaffolds and investigated for use in skin, bone, cartilage, nerve, blood vessel and tendon tissue engineering. Such studies have led to the commercialization of several electrospun products for treating a variety of clinical needs. Ultimately, the further development of electrospinning and electrospun nanofibrous scaffolds holds great promise for a variety of tissue engineering applications and may improve the quality of life for patients around the world.

Acknowledgements

This work was financially surpported by the Fundamental Research Funds for the Central Universities (No. 2232019A3-07), the National Key Research Program of China (Nos. 2016YFA0201702 of 2016YFA0201700), the National Nature Science Foundation of China (No. 31771023), the Science and Technology Commission of Shanghai Municipality (No. 19441902600), the Fundamental Research Funds for the Central Universities and Graduate Student Innovation Fund of Donghua University (No. CUSF-DH-D-2020061). The authors acknowledge King Saud University, Riyadh, Saudi Arabia, for funding this work through Researchers Supporting Project number (RSP-2020/30).

Reference

DOI

URL

PMID

[Cited within: 2]

Electrospinning is a versatile and viable technique for generating ultrathin fibers. Remarkable progress has been made with regard to the development of electrospinning methods and engineering of electrospun nanofibers to suit or enable various applications. We aim to provide a comprehensive overview of electrospinning, including the principle, methods, materials, and applications. We begin with a brief introduction to the early history of electrospinning, followed by discussion of its principle and typical apparatus. We then discuss its renaissance over the past two decades as a powerful technology for the production of nanofibers with diversified compositions, structures, and properties. Afterward, we discuss the applications of electrospun nanofibers, including their use as

DOI

URL

PMID

[Cited within: 1]

Nerve tissue engineering (NTE) is one of the most promising methods to restore central nerve systems in human health care. Three-dimensional distribution and growth of cells within the porous scaffold are of clinical significance for NTE. In this study, an attempt was made to develop porous polymeric nano-fibrous scaffold using a biodegradable poly(L-lactic acid) (PLLA) for in vitro culture of nerve stem cells (NSCs). The processing of PLLA scaffold has been carried out by liquid-liquid phase separation method. The physico-chemical properties of the scaffold were fully characterized by using differential scanning calorimetry and scanning electron microscopy. These results confirmed that the prepared scaffold is highly porous and fibrous with diameters down to nanometer scale. As our nano-structured PLLA scaffold mimics natural extracellular matrix, we have intended this biodegradable scaffold as cell carrier in NTE. The in vitro performance of NSCs seeded on nano-fibrous scaffold is addressed in this study. The cell cultural tests showed that the NSCs could differentiate on the nano-structured scaffold and the scaffold acted as a positive cue to support neurite outgrowth. These results suggested that the nano-structured porous PLLA scaffold is a potential cell carrier in NTE.

DOI

URL

PMID

[Cited within: 1]

Highly periodic, geometrically directed, anisotropic Se-Pb films have been synthesized at room temperature from an isotropic aqueous solution without the use of physical templates by photoelectrodeposition using a series of discrete input illumination polarizations and wavelengths from an unstructured, uncorrelated, incoherent light source. Dark growth did not generate deposits with substantial long-range order, but growth using unpolarized illumination resulted in an ordered, nanoscale, mesh-type morphology. Linearly polarized illumination generated Se-Pb deposits that displayed an ordered, highly anisotropic lamellar pattern wherein the long axes of the lamellae were aligned parallel to the light polarization vector. The pitch of the lamellar features was proportional to the input light wavelength, as confirmed by Fourier analysis. Full-wave electromagnetic and Monte Carlo growth simulations that incorporated only the fundamental light-matter interactions during growth successfully reproduced the experimentally observed morphologies and quantitatively matched the pattern periodicities. Electrochemical postprocessing of the as-deposited Se-Pb structures resulted in the generation of stoichiometric, crystalline PbSe while preserving the nanopatterned morphology, thus broadening the genus of materials that can be prepared with controlled three-dimensional morphologies through maskless photoelectrodeposition.

DOI

URL

PMID

[Cited within: 1]

With the emergence of nanotechnology, researchers become more interested in studying the unique properties of nanoscale materials. Electrospinning, an electrostatic fiber fabrication technique has evinced more interest and attention in recent years due to its versatility and potential for applications in diverse fields. The notable applications include in tissue engineering, biosensors, filtration, wound dressings, drug delivery, and enzyme immobilization. The nanoscale fibers are generated by the application of strong electric field on polymer solution or melt. The non-wovens nanofibrous mats produced by this technique mimics extracellular matrix components much closely as compared to the conventional techniques. The sub-micron range spun fibers produced by this process, offer various advantages like high surface area to volume ratio, tunable porosity and the ability to manipulate nanofiber composition in order to get desired properties and function. Over the years, more than 200 polymers have been electrospun for various applications and the number is still increasing gradually with time. With these in perspectives, we aim to present in this review, an overview of the electrospinning technique with its promising advantages and potential applications. We have discussed the electrospinning theory, spinnable polymers, parameters (solution and processing), which significantly affect the fiber morphology, solvent properties and melt electrospinning (alternative to solution electrospinning). Finally, we have focused on varied applications of electrospun fibers in different fields and concluded with the future prospects of this efficient technology.

DOI

URL

PMID

[Cited within: 1]

Due to their size and tailorable physicochemical properties, nanomaterials are an emerging class of structures utilized in biomedical applications. There are now many prominent examples of nanomaterials being used to improve human health, in areas ranging from imaging and diagnostics to therapeutics and regenerative medicine. An overview of these examples reveals several common areas of synergy and future challenges. This Nano Focus discusses the current status and future potential of promising nanomaterials and their translation from the laboratory to the clinic, by highlighting a handful of successful examples.

DOI

URL

PMID

[Cited within: 1]

UNLABELLED: The evolution of synthetic RNAi faces the paradox of interfering with the human biological environment. Due to the fact that all cell physiological processes can be target candidates, silencing a precise biological pathway could be challenging if target selectivity is not properly addressed. Molecular biology has provided scientific tools to suppress some of the most critical issues in gene therapy, while setting the standards for siRNA clinical application. However, the protein down-regulation through the mRNA silencing is intimately related to the sequence-specific siRNA ability to interact accurately with the potential target. Moreover, its in vivo biological fate is highly dependent on the successful design of a vehicle able to overcome both extracellular and intracellular barriers. Anticipating a great deal of innovation, crucial to meet the challenges involved in the RNAi therapeutics, the present review intends to build up a synopsis on the delivery strategies currently developed. FROM THE CLINICAL EDITOR: This review discusses recent progress and pertinent limiting factors related to the use of siRNA-s as efficient protein-specific

DOI

URL

PMID

[Cited within: 1]

Biomaterials have played an increasingly prominent role in the success of biomedical devices and in the development of tissue engineering, which seeks to unlock the regenerative potential innate to human tissues/organs in a state of deterioration and to restore or reestablish normal bodily function. Advances in our understanding of regenerative biomaterials and their roles in new tissue formation can potentially open a new frontier in the fast-growing field of regenerative medicine. Taking inspiration from the role and multi-component construction of native extracellular matrices (ECMs) for cell accommodation, the synthetic biomaterials produced today routinely incorporate biologically active components to define an artificial in vivo milieu with complex and dynamic interactions that foster and regulate stem cells, similar to the events occurring in a natural cellular microenvironment. The range and degree of biomaterial sophistication have also dramatically increased as more knowledge has accumulated through materials science, matrix biology and tissue engineering. However, achieving clinical translation and commercial success requires regenerative biomaterials to be not only efficacious and safe but also cost-effective and convenient for use and production. Utilizing biomaterials of human origin as building blocks for therapeutic purposes has provided a facilitated approach that closely mimics the critical aspects of natural tissue with regard to its physical and chemical properties for the orchestration of wound healing and tissue regeneration. In addition to directly using tissue transfers and transplants for repair, new applications of human-derived biomaterials are now focusing on the use of naturally occurring biomacromolecules, decellularized ECM scaffolds and autologous preparations rich in growth factors/non-expanded stem cells to either target acceleration/magnification of the body's own repair capacity or use nature's paradigms to create new tissues for restoration. In particular, there is increasing interest in separating ECMs into simplified functional domains and/or biopolymeric assemblies so that these components/constituents can be discretely exploited and manipulated for the production of bioscaffolds and new biomimetic biomaterials. Here, following an overview of tissue auto-/allo-transplantation, we discuss the recent trends and advances as well as the challenges and future directions in the evolution and application of human-derived biomaterials for reconstructive surgery and tissue engineering. In particular, we focus on an exploration of the structural, mechanical, biochemical and biological information present in native human tissue for bioengineering applications and to provide inspiration for the design of future biomaterials.

DOI

URL

PMID

[Cited within: 1]

The rising incidence of bone disorders has resulted in the need for more effective therapies to meet this demand, exacerbated by an increasing ageing population. Bone tissue engineering is seen as a means of developing alternatives to conventional bone grafts for repairing or reconstructing bone defects by combining biomaterials, cells and signalling factors. However, skeletal tissue engineering has not yet achieved full translation into clinical practice as a consequence of several challenges. The use of additive manufacturing techniques for bone biofabrication is seen as a potential solution, with its inherent capability for reproducibility, accuracy and customisation of scaffolds as well as cell and signalling factor delivery. This review highlights the current research in bone biofabrication, the necessary factors for successful bone biofabrication, in addition to the current limitations affecting biofabrication, some of which are a consequence of the limitations of the additive manufacturing technology itself.

DOI

URL

PMID

[Cited within: 1]