1. Introduction

Single crystal (SX) superalloys are being widely used as blades and vanes in gas turbines and aero-engines. The second generation Ni-based SX superalloy has been most widely used as aero-engine turbine blade material [[1], [2], [3], [4], [5]]. Under the harsh environment, the creep damage of the superalloy parts will occur inevitably. In this case, the main strengthening phase becomes sphered, coarsened and rafted. Creep holes will greatly affect the high-temperature performance and service life of superalloy parts [[6], [7], [8]]. Generally, there are two ways to deal with the part after creep damage, extending the life of parts or replacing the parts. Trying to extend the life of the parts can effectively reduce the cost compared with replacing them.

Currently, it has been reported that the most useful renovation technology is recovery heat treatment technology, including hot isostatic pressing (HIP) [4,5,[9], [10], [11], [12], [13], [14], [15]] and rejuvenation heat treatment (RHT) [[16], [17], [18], [19], [20], [21], [22], [23], [24], [25]]. Comparing with the HIP, RHT process is more suitable for components after short time service, there is only a small amount of deformation and no significant creep holes. Additionally, RHT is also cheaper and simpler compared with the HIP [13,[10], [11], [12], [13], [14], [15]]. However, limited information is available about the effect of RHT on the SX superalloy [[16], [17], [18]], in which only the effects of RHT in the interior of the sample, but not the changes on the surface area were reported.

During the operation at high temperature, oxidation and recrystallization (RX) may occur on the surface of the SX components. The surface composition of the superalloy will change during oxidation, which will affect its performance. The RX grain will also introduce the weak grain boundaries and decrease the high temperature properties, especially when the grain boundary strengthening elements are removed in SX superalloy. Unfortunately, fewer reports have focused on the effects of RHT on the structure of the superalloy components after short time service. For these reasons, it would be meaningful to study the SX superalloy treated by RHT on the surface and internal microstructure, which will be very helpful for guiding the processing of RHT.

A second-generation Ni-based SX superalloy has been studied in this work. Creep tests were interrupted to simulate creep damage of the blade during service. After RHT, the microstructural evolution and element distribution on the surface and in the interior of the superalloy were studied. The feasibility of RHT is modified by the structure evolution and the creep life of samples.

2. Experimental

The second generation Ni-based SX superalloy in as cast condition was employed. The chemical compositions of the superalloy (wt%) are shown in Table 1, in which the total amount of Mo, Ta and W are presented. The master alloy was melted in the vacuum induction furnace ZG-0.01, and then SX cylinder bars with the size of 16 mm in diameter and 220 mm in length were prepared through a high rate solidification (HRS) technique. The orientation along the longitudinal axis of the SX bars used for present work was less than 15° from <001 > .

Table 1 Chemical compositions of the second-generation superalloys in this work (wt%).

| Cr | Co | Mo + Ta + W | Al | C | B | Re | Hf | Ni |

|---|---|---|---|---|---|---|---|---|

| 7.0 | 7.5 | 13 | 6.3 | 0.005 | 0.004 | 3 | 0.15 | Bal. |

The as cast samples were cut to 76 mm in length by electrical discharge machining (EDM), and were further subjected to standard heat treatment (SHT), including solution treatment at 1290 °C for 2 h and aged treatment at 1100 °C for 4 h, 1050 °C for 4 h and 900 °C for 4 h. All the heat treatments were followed by air cooling. The superalloy was machined into creep sample, as shown in Fig. 1. The creep test was conducted at 1100 °C/137 MPa in air, and the tests were interrupted to obtain a variety of deformations. The samples were loaded after reaching 1100 °C for 10 min, and the loading was stopped until reaching the pre-designed amount of total deformation. When the sample size did not change any more, the heating was stopped and the samples were taken out from the furnace for further analysis.

Fig. 1.

Fig. 1.

Creep sample morphology.

The samples after creep test were sectioned transversely into 2 mm in thickness. Partial samples were subjected to RHT, which is carried out with the same process as SHT. The residual samples are for comparison analysis. In order to avoid oxidation, the samples for SHT were sealed in silica glass tubes backfilled with argon gas. Both samples with, and without RHT were mounted, ground with SiC papers from 150 grit to 2000 grit, and then polished. The polished samples were etched in the reagent consisting of 100 ml HCl + 5 ml H2SO4 + 20 g CuSO4 + 80 ml H2O, and then analyzed with the INSPECT F50 scanning electron microscopy (SEM) on microstructure. The composition was analyzed by energy dispersive X-ray spectroscopy (EDS). The crystal orientation was obtained by electron backscattered diffraction (EBSD).

3. Results

3.1. Initial microstructures

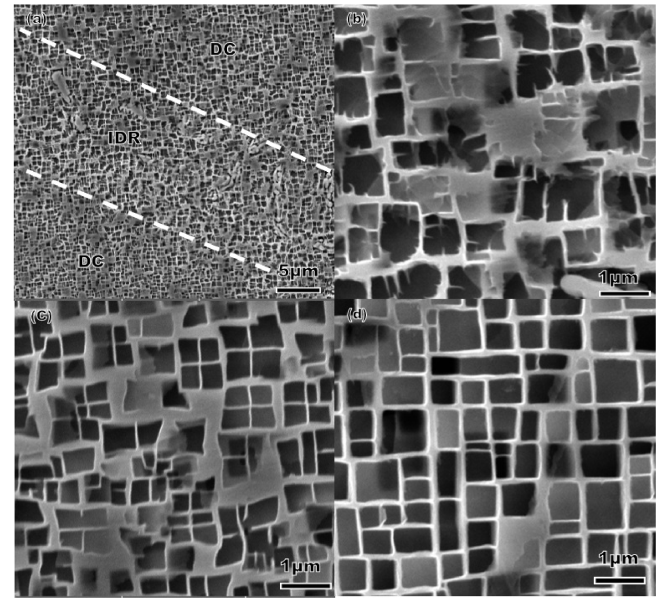

Dendritic characteristics can be found in as-cast superalloy (Fig. 2(a)). The regular cubic γ' phases with the irregular γ matrix wrapped around are observed in the dendritic arms (DAs) (Fig. 2(b)), while coarse and irregular cubic γ' phases with spiny γ matrix emerged in the interdendritic regions (IDRs) (Fig. 2(c)). After SHT, the microstructure of the alloy becomes homogeneous. Regular cubic γ' precipitates and narrow γ matrix can be found, and it’s hard to separate the DAs and the IDRs. The volume fraction of γ' precipitate at the DAs and the IDRs before SHT and inside the samples after SHT are measured as 54 %, 72 % and 63 %, respectively.

Fig. 2.

Fig. 2.

Microstructures of alloys in as-cast (a, b, c) and after SHT (d).

3.2. Interrupted creep test

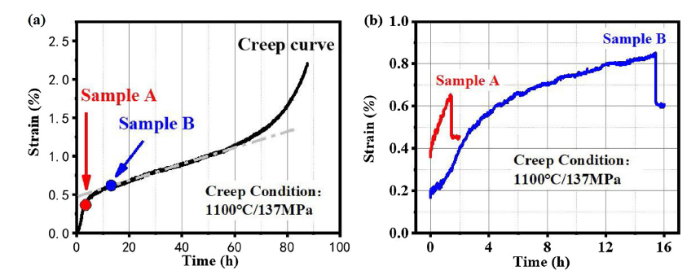

The creep curve is shown in Fig. 3(a), which was recorded when the loading completed. From the slope of the curve, the time that alloy enters the second stage of creep can be determined. According to this curve, two creep interrupt tests were designed. The sample A was interrupted before it enters the second stage of creep, the sample B was interrupted after that as well. The location of the breakpoint of two samples is indicated in the curve.

Fig. 3.

Fig. 3.

The creep curve of the alloy (a) and creep interruption curves of samples with two kinds of total strain (b) at 1100 °C/137 MPa.

Creep curves of the two samples are shown in Fig. 3(b). It should be mentioned that the sample has been deformed during the loading, which is called the pre-deformation and can be converted to pre-strain. Different samples have different pre-strains. For this reason, the two curves don’t start at the origin. When the strain reached the target value, the tests were interrupted and the strain of the samples would decrease by force of elasticity. Four kinds of strains of two samples are shown in Table 2.

Table 2 Results of different creep interruption tests (%).

| Samples | Total strain | Pre-strain | Elastic strain | Plastic strain |

|---|---|---|---|---|

| A | 0.65 | 0.37 | 0.19 | 0.46 |

| B | 0.85 | 0.17 | 0.25 | 0.60 |

As shown in Table 2, although there are different pre-strains for the two samples, the ratios of plastic strain to total strain of the two samples are similar (70.8 % and 70.6 %). It is indicated that the difference of pre-strain would not affect the plastic strain which is also known as residual strain. Different pre-strain means the time for total strain to reach the same value is different, which will be discussed further in the following part of this article.

3.3. Interior microstructure before and after RHT

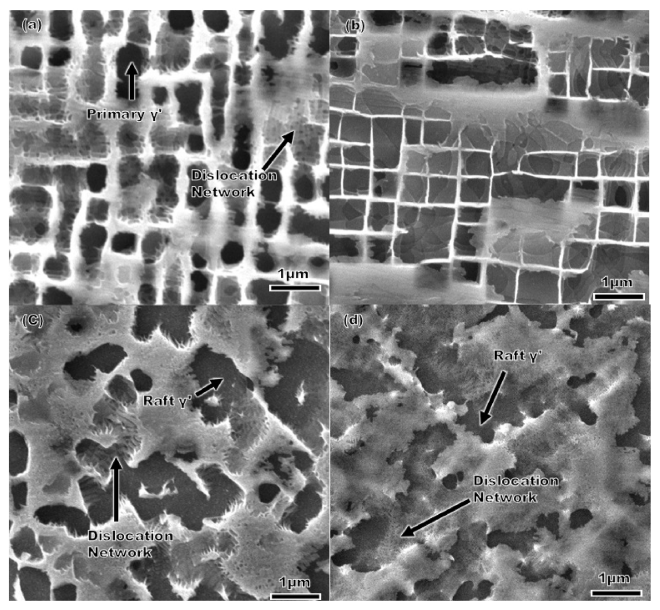

The microstructure of the sample A, with 0.65 % creep strain, were examined. The spherical primary γ', coarse γ matrix as well as the dislocation network at the γ/γ' can be found near surface area (Fig. 4(a)). In the interior area (Fig. 4(b)), only the regular cubic γ' and the narrower γ matrix are found. When the creep enters the secondary stage, the dislocation network appears on both surface (Fig. 4(c)) and inside the sample B (Fig. 4(d)), while the primary γ' and the γ matrix are irregular. It is worth mentioning that the dislocation network can be observed through SEM when the corrosion of the sample is severe [[26], [27], [28]]. It is thought that the dislocation accumulation results in the dislocation network, which leads to the deformation of the sample. And all these changes of the dislocation network, the γ' precipitated phase and the γ matrix start at the surface in the primary creep, and they will be found in the interior when the deformation is large enough.

Fig. 4.

Fig. 4.

The interior microstructures of the sample A (a, b) and the sample B (c, d) before RHT.

The rafted γ' phase as well as the coarse γ matrix are related to the diffusion of the elements and the stress. According to the test conditions, it can be known that, with the continuous creep, the stress accumulation and oxidation degree of samples will increase, and both will accelerate the diffusion of elements. Particularly, the oxidation consumes Al and Cr to form the oxide layer, which causes the difference in the concentration of such elements from the interior to the surface. That’s why the morphology of γ' and γ changes first at surface. And it is reported that the stress could promote the phase transition [29]. Under high temperature and stress, although the temperature does not reach the solid solution temperature, the stress will accelerate the migration of the elements and cause γ' to be dissolved. The γ matrix dissolves the primary γ' resulting in the enrichment of γ' forming element in γ, which results in the spheroidization or rafting of primary γ' and the coarsening of γ channel. The analysis of the surface will be discussed in detail in the following sections.

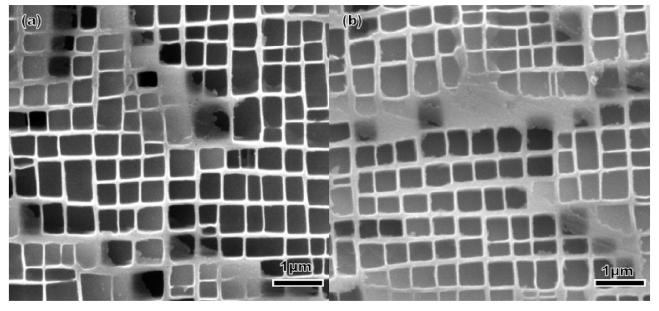

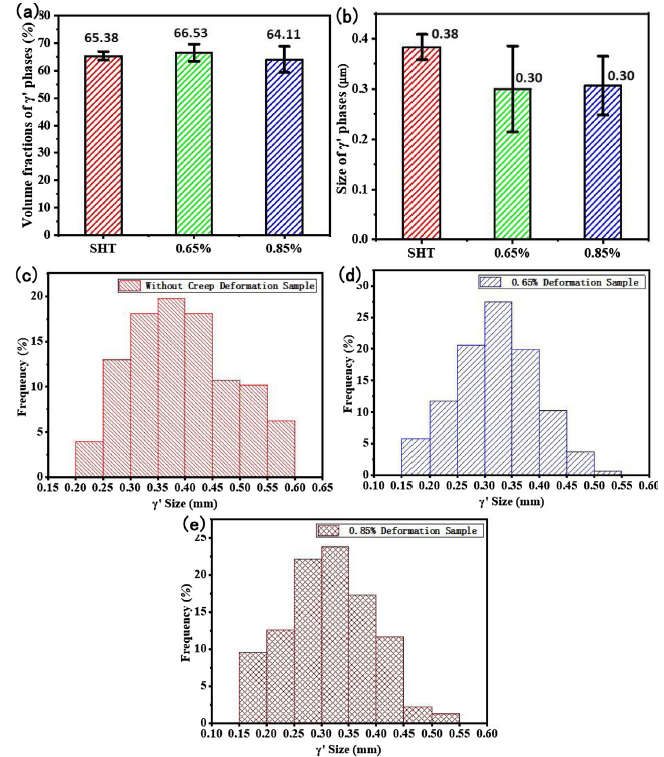

Similar microstructure was obtained by the same RHT for the samples with different strains (Fig. 5(a) and (b)). Both samples have regular cubic primary γ' and γ matrix, but there is no dislocation network. This means that the γ' phase dissolved and re-precipitated to regular cubic during RHT, and the dislocation network also disappeared in this process. RHT is effective by comparing the interior microstructures of samples with those after SHT. Then the volume fraction, the size and the distrubution of γ' in the sample after SHT and RHT are further statistically analyzed (Fig. 6). Four different areas of each sample were analyzed. The average volume fraction (Fig. 6(a)) of each sample are 65.38 %, 66.53 % and 64.11 % with size (Fig. 6(b)) of 0.38 μm, 0.30 μm and 0.30 μm, respectively. The decrease of the γ' size of the samples after RHT may be related to the reduction of Al [30].

Fig. 5.

Fig. 5.

Interior microstructures of the sample A (a) and the sample B (b) after RHT.

Fig. 6.

Fig. 6.

The average volume fraction (a), the average size (b) and the distribution (c, d, e) of γ' phase in the samples after SHT and RHT.

By comparing the microstructures of samples after SHT, creep and RHT, it can be found that although the average size of the γ' has been slightly reduced than that after SHT, the microstructure and the average volume fraction of the γ' in samples after RHT are quite close to the sample after SHT. The γ' phase is the main strengthening phase in superalloys. Its shape and volume fraction determine the properties of the alloy. Therefore, the similar γ' phases indicates similar properties of samples after SHT and RHT. Subsequently, complete creep tests have be performed after creep interruption tests and RHT to confirm this.

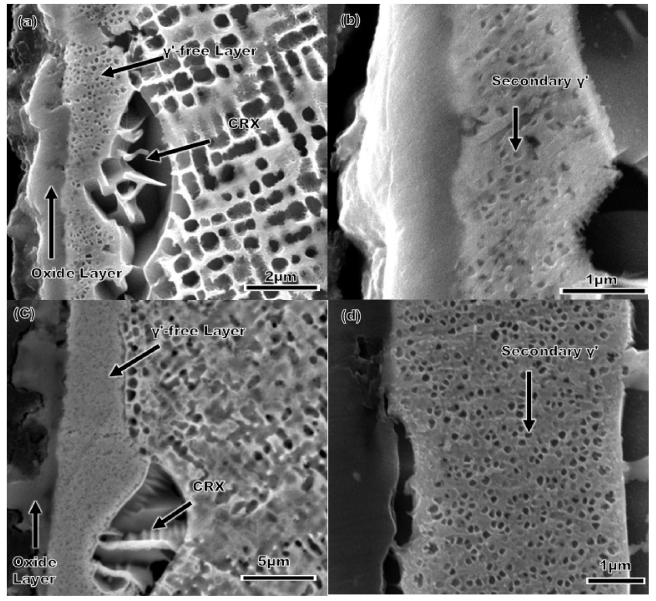

3.4. Microstructures in the surface before and after RHT

Oxide layer was formed on the surface of the sample A during creep, and the γ'-free layer is just below this layer (Fig. 7(a)). The cellular recrystallization (CRX) could be found in between the γ'-free layer and the interior region which has the spherical primary γ' and the coarse γ. There are still tiny secondary γ' phase, as shown in Fig. 7(b). By comparing with the sample A, the same microstructures could be observed at the surface of the sample B (Fig. 7(c)). It should be pointed out that the coarsening of the interior microstructures has increased, and the γ'-free layer in sample B is thicker than that in the sample A (Fig. 7(d)).

Fig. 7.

Fig. 7.

The surface microstructures of the sample A (a, b) and the sample B (c, d) before RHT.

The formation of the γ'-free layer is due to oxidation. The oxide layer is rich in Al, while the γ'-free layer is depleted. EDS result proves that Al in the inner surface of the alloy diffuses outward to form an oxide layer with O in the air. When the Al is consumed, it is hard for the primary γ' to precipitate in the γ'-free layer, and the secondary γ' forms because of the diffusion of Al from the interior matrix. And as the oxidation time increases, the thickness of the γ'-free layer also increases.

The RX behavior of the SX superalloy is mainly correlated with the free surface and the oxidation. The CRX has been observed in some places under the γ'-free layer. Based on previous studies [[31], [32], [33], [34]], the RX requires less energy to nucleate on the surface or the interface than it does inside the grains. With the nucleation of new RX grains, interfacial energy will increase due to the formation of a new interface. This leads to a higher possibility of the heterogeneous nucleation of RX in the surface instead of the internal area. Furthermore, there is not enough energy to nucleate in the internal area, because the energy is consumed for nucleation at the surface. And these mean that the RX starts at the surface instead under the γ'-free layer. So, there must be the RX in the γ'-free layer which has a similar microstructure to the equiaxed recrystallization (ERX). The difference of morphology is mainly due to the different element content. The nucleation and growth of the RX is related to the high diffusivity of the migrated grain boundaries [33]. When the RX grain boundary migrates in the matrix, the γ' phase will be dissolved. This will cause oversaturation of the γ' forming elements in the grain boundary, and large γ' phase will precipitate and grow, which is the CRX. However, there is less γ' phase to be dissolved in the γ'-free layer, so the ERX will form instead of the CRX. In simple terms, RX nucleates and grows from the lower energy surface. As RX grows up, RX grain boundary migrates inward, and the boundary absorbs elements in front of it and precipitates excess elements behind it. The ERX forms in the γ'-free for the less Al there. On the contrary, there is more Al in the matrix, so CRX can be observed.

The surface microstructure of the two samples after RHT is shown in Fig. 8, which can be divided into three parts. They are the γ'-free layer (6.76 μm, 7.38 μm for each sample), the transition layer (10.43 μm, 10.66 μm) and the matrix alloy from the outside. The structure of the γ'-free layer after RHT is the same as the one after creep tests (Fig. 7(b) and (d)). Both of the two γ'-free layer after RHT and creep have less content of element Al and less size of γ' phases than the matrix. And the structure of matrix has already been mentioned above as interior microstructure of samples (Fig. 5). Fig. 8(c) and (d) shows the microstructures of the transition layer of two samples where the γ' phase are spherical. The depth of the γ'-free layer and the transition layer of sample A are close but a little bit less than the one of sample B. The depth of the two layers of each samples are less than 20 μm. RX has been found in some place with the maximum depth 15.35 μm (Fig. 8(e)). And the cubic γ' can also be observed in the area within the RX close to the matrix after RHT (Fig. 8(f)). It is indicated that RHT is also valid for the part of the RX. And precipitation have been observed at the grain boundary of RX.

Fig. 8.

Fig. 8.

The surface microstructures of the sample A (a, c, e) and the sample B (b, d, f) after RHT.

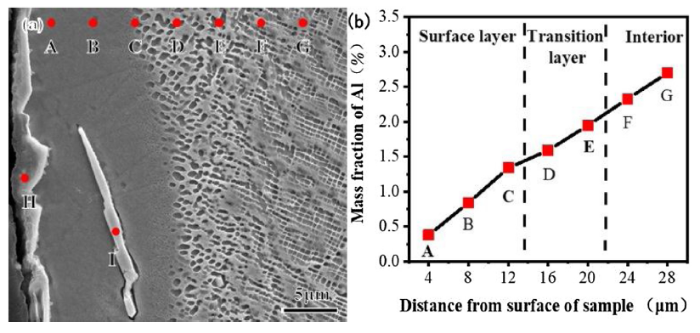

The morphology of the γ' phase in the superalloy is closely related to its composition. For this reason, EDS is performed to analyze the distribution of the elements (Fig. 9(a)). The change of Al with the distance from surface is shown in Fig. 9(b), the composition of each region and the precipitates have been shown in Table 3 as well. As shown in the curve, the content of Al increases with distance from the surface. Al is the main component of the γ' phase, the difference of Al content leads to the different morphology of the γ' phase. According to the results of SEM and EDS, when the content of Al is relatively low, the γ' phase could precipitate and form tiny particles. When there is more Al, the γ' phase could precipitate and grow as a sphere. If there is enough Al to form the γ' phase, there will be enough γ' phase gather together to form the cubic γ' phase. It can be inferred that the Al in a certain range will form a certain shape of γ' phase. So, there is the cubic γ' phase near the matrix of RX after RHT, while there is still the tiny γ' near the surface. And this concentration gradient of Al is related to the diffusion of the element during RHT. Oxidation consumes a large amount of Al on the surface of the alloy during creep, so the γ'-free layer formed. Then Al diffuses to the γ'-free layer from the matrix, which causes the formation of the secondary γ' in the γ'-free layer and the spherical γ' phase in the matrix near the surface. Because the decreasing content of Al element by the oxidation is faster than the increase by diffusing from the matrix, the concentration gradient of Al exists between the matrix and the γ'-free layer. After RHT, a transition layer is formed which could reduce the concentration gradient between the matrix and the γ'-free layer. For this reason, the γ' phase in the transition layer is spherical and its size is between the one in the γ'-free layer and the matrix. In general, RHT affected zone (RAZ), including the γ'-free layer and the transition layer, is generally less than 20 μm, which has less effect on the properties of the alloy.

Fig. 9.

Fig. 9.

The variation of Al element content with distance.

Table 3 The composition of each region and precipitated phase (wt%).

| Location | Ni | Co | Cr | W | Ta | Mo | Re | Al | O |

|---|---|---|---|---|---|---|---|---|---|

| Surface precipitate (H) | 21.17 | 2.53 | 20.93 | 22.09 | 19.63 | 6.12 | 1.78 | 0.05 | 5.71 |

| γ'-free layer (B) | 64.27 | 7.90 | 8.68 | 4.79 | 10.41 | 1.17 | 1.93 | 0.84 | — |

| Transition layer (D) | 68.87 | 8.92 | 8.12 | 5.64 | 2.26 | 1.77 | 2.85 | 1.59 | — |

| Interior (G) | 61.73 | 10.19 | 7.78 | 8.35 | 5.42 | 0.92 | 2.91 | 2.70 | — |

| Inside precipitate (I) | 25.52 | 2.04 | 11.01 | 25.13 | 20.16 | 7.20 | 8.91 | 0.01 | — |

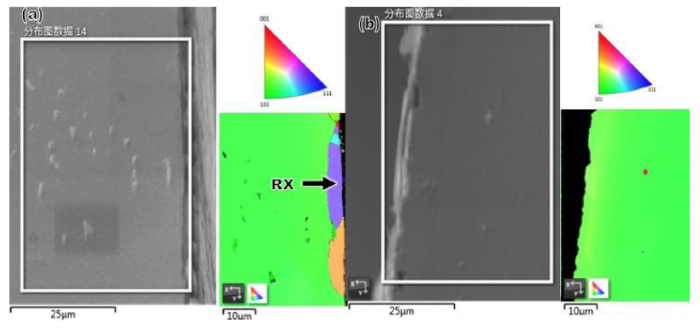

It can be found in Table 3 that both the surface and the internal precipitates are rich in W, Ta, Mo. In addition, there are O and more Cr in the surface precipitate, while there is more Re inside the precipitate. Despite the samples are sealed in tube, there are still some oxides on the surface before the sealing, which is the reason for the presence of O in the surface precipitate. The presence of precipitates after RHT can be deduced by the element diffusion and the grain boundary. Oxidation leads to the depletion of Al and changes the composition of the alloy, then affects the solubility of refractory elements in the alloy. Because less energy is required, refractory element usually precipitates out at the grain boundary. So, after heat treatment for longer time, with the migration of the RX grain boundary, refractory elements gather and form precipitate at the RX grain boundary and the surface of alloy. EBSD is performed to prove that a small amount of RX is discontinuous and relatively flat around the sample surface (Fig. 10), and the size of RX is less than the RAZ. According to the above analysis, the presence of the RX and the precipitate will not have much effect on performance, because the precipitation may only appear at the surface or the RX boundary, and the RX is less than the RAZ.

Fig. 10.

Fig. 10.

EBSD results of the surface of sample B after RHT.

3.5. Complete creep test after RHT

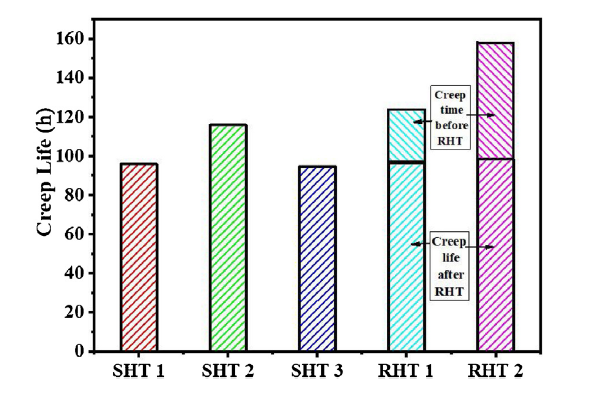

It has been proved that RHT can effectively restore the internal structure of the alloy and produce less influence on the surface. So the complete creep tests were performed after creep interruption test and RHT to compare the effect of RHT on the creep life. The result is shown in Fig. 11. As mentioned before, the time required to reach the same total strain is different for the different pre-strain. It costs 28.67 h to reach the 0.85 % total strain for sample RHT1, while 61.18 h for sample RHT2. The average creep life of the three samples after SHT is 102.03 h, while the average creep life of the two samples after RHT is 97.39 h. It is indicated that RHT can restore the life of the samples after creep deformation to the average life of the samples after SHT. And this date also means that the creep time before RHT is the increased life, which increased life expectancy by at least 28 % and by as much as 59 %.

Fig. 11.

Fig. 11.

The creep life of samples after SHT and after RHT.

4. Discussion

The structures of both the surface and the interior have been discussed before and after RHT respectively. By analyzing changes in the oxidation layer, the γ'-free layer, the RX and the γ' phase, it can be inferred that all the changes are due to the oxidation and stress, which are ascribed to the diffusion of elements and the energy of nucleation. Therefore, changes in the sample as a whole can be further discussed from these two aspects.

On one hand, all changes in microstructural morphology can be explained by diffusion of elements. Before RHT, due to the high temperature creep test in air, the surface of the sample is oxidized. And Al from the surface diffuses outward to form the oxidation layer (Al2O3), so there is an Al depletion layer. Because of the absence of Al, the primary γ' is not stable in this layer which is called the γ'-free layer. At the same time, Al diffuses from the matrix to the γ'-free layer, and these Al will also diffuse outward to form Al2O3 layer. This is the reason for the γ'-free layer formed and increased with the creep time. However, the oxide layer can’t consume all the Al in the γ'-free layer, the secondary γ' is precipitated as tiny particles. And these tiny particles can’t grow for the absence of Al. The existence of the secondary γ' in the γ'-free layer has been explained. Since a large concentration gradient between the γ'-free layer and the matrix, Al on the side close to the surface in the matrix prefers to diffusing outward. The change of Al element concentration leads to the change of the morphology of the γ phase and the γ' phase by the interaction of temperature and stress. The γ' phase is spherical and abnormal, while the γ phase is coarse. That’s why the change of matrix started from the surface. After RHT, although there are few oxides at the surface of alloy, the oxidation didn't continue during RHT. Solid solution and aging were carried out in enough time, while the element also diffused. The difference of Al element concentration between the γ'-free layer and the matrix is large before RHT. After a certain amount of time of diffusion, the concentration of Al increases uniformly as the distance from the surface increases. The different forms of the γ' phase can also be expressed by the different content of Al. The γ' phase precipitates as tiny particles firstly, and the spherical γ' phase forms because of more Al, then cubic γ' phase formed finally for the enough Al. So, three-layers structure can be observed at the surface of the alloy. As for the microstructure of interior matrix, the composition of the alloy did not change much, the elements diffused outward have little effect on the structure because of the less γ'-free layer, so the structure appears as that after SHT.

On the other hand, the formation of RX at the surface can be explained by the energy of nucleation, and the different forms of RX are due to the different composition of the elements. During creep, the alloy will recrystallize under the combined action of stress and temperature. RX occurs at the surface because it requires less nucleation energy. The growth of RX is the process of absorbing matrix elements in the front edge of the boundary and precipitating in the rear. Since the content of Al in the γ'-free layer is low, the precipitation of γ' phase in the γ'-free layer is very fine. On the contrary, there are more γ' forming elements in the matrix. As the interface moves forward, large amounts of γ' forming elements are precipitated quickly. Since the precipitation is faster, the γ' phase is cellular. That’s why RX appeared two different forms in the γ'-free layer and the matrix. Since the elements absorbed by the grain boundary are precipitated in the rear, the content of Al element at both ends of the grain boundary does not change much. So, there are similar microstructures at both ends of the grain boundary after RHT. And if RX grain is big enough to contain the γ'-free layer and the matrix, the concentration gradient of Al will be there to form multilayer structure of γ' phase in RX as well. As for the precipitate phase with refractory elements, it is related to grain boundary and elemental diffusion. Al diffusion causes the change of composition which also changes the solubility of refractory elements. And refractory elements are enriched and precipitated at grain boundary and surface for the less energy they need.

According to results and analysis mentioned above, it can be proved that RHT is effective for samples after creep deformation, which can restore the life of the second creep of the samples to close to the average life of the sample after SHT, and RHT can also improve the total creep life for 28 %-59 % as the time for the first creep time. To compare with the samples after SHT, the samples after RHT have similar microstructure, volume fraction, average size and size distribution, but the difference is that there are a RAZ which include the three-layer structure, RX and precipitates composed of refractory elements at the surface. However, the RAZ is less than 20 μm in depth, it will cause small impact on the properties of the alloy.

5. Conclusions

The present work investigates the effect of the rejuvenation heat treatments on the creep of the second generation Ni-based SX superalloy. After RHT, total creep life has been increased about 28 %-59 % for the tested samples. Two main conclusions can be drawn from the results:

(1) The rafted γ' phase in the interior of samples can be transformed into the cubic γ' phase by RHT, and the creep property of samples can be also repaired as the initial. During the creep, oxidation and stress work together on the surface of the sample, and they lead to the form of RHT affected zone, which include the γ'-free layer, the transition layer and the recrystallization. However, RHT affected zone is less than 20 μm in depth totally, and it can’t influence the creep property.

(2) The morphology of γ' phase in samples after RHT is related to the element content of Al. Al diffuses outward to form the oxide layer at the surface of samples, and this results in the absence of Al in the inner surface, so the γ'-free layer formed. At the same time, Al also diffuses from the matirx to the γ'-free layer, and this leads to the concentration gradient of Al, then the transition layer has been observed.

Acknowledgements

This work was financially supported by the National Science and Technology Major Project (No. 2017-VI-0002-0072), the National Key R&D Program of China (Nos. 2017YFA0700704, 2018YFB110660 and 2017YFB1103800), the National Natural Science Foundation of China (Nos. 51601192, 51671188, 51701210 and 51771190), the Youth Innovation Promotion Association, the Chinese Academy of Sciences and State Key Lab of Advanced Metals and Materials Open Fund (No. 2018-Z07).

Reference

Second-Generation Nickel-Base Single Crystal Superalloy

in: Superalloys,

Practical Experience with the Development of Superalloy Rejuvenation

in: Proceedings of ASME Turbo Expo 2009,

Assessment of Damage Accumulation and Property Regeneration by Hot Isostatic Pressing and Heat Treatment of Laboratory-Tested and Service Exposed IN738LC

in:

γ' phase caused by creep deformation, caused a nonuniform microstructure of γ /γ' matrix after aging treatments, and resulting in partially recovering the baseline creep property. However, the solution treatment at 1240 and 1250 ℃ could not only dissolve the coarse γ' phase but also reduce the fraction of residual γ' eutectic significantly, and then regain a uniform microstructure of γ /γ' matrix after aging treatments. Hence, the effect of rejuvenation was further improved, maintaining or exceeding the baseline creep property.]]>

γ′ precipitates microstructure of creep degraded GTD111 superalloy and the evolution process of γ′ precipitates under different stages of re-heat rejuvenation treatment were investigated. The results show that solid solution treatment at the temperature range of 1180~1220 ℃ can effectively dissolve the coarsened and rafted primary γ′ precipitates and promote uniform precipitation of fine size secondary γ′ precipitates in the damaged alloy, meanwhile the size of secondary γ′ precipitates decreases with the increase of solution temperature and cooling rate. However, when the solid solution temperature increases to 1240 ℃, incipient melting in the interdendritic region ocurrs. High temperature ageing results in continued growth of the secondary γ′ precipitates and precipitation of tertiary γ′ precipitates. The size and cubic degree of the secondary γ′ precipitates increase with the increase of ageing temperature and soaking time. The tertiary γ′ precipitates continue to precipitate and grow during low temperature ageing process. The suitable re-heat rejuvenation parameters are 1220 ℃, 2 h, AC+1121 ℃, 2 h, AC+843 ℃, 24 h, AC. The rupture life of rejuvenated alloy under the condition of 750 ℃ and 843 MPa is up to 65 h, which is about 1.3 times of that of virgin alloy, due to its more volume fraction of duplex size γ′ precipitates after re-heat rejuvenation treatment.]]>

WeChat

WeChat