Despite the great efforts dedicated to metallic glasses (MGs), their structure still remains a mystery to be understood. With comparison to the existing micromechanical models, such as the free-volume and shear transformation zone (STZ) models, we first discuss in this article our recently proposed ‘core-shell’ model, which contains a solid-like matrix and liquid-like inclusions. This serves as the theoretical basis to understand the structural heterogeneity in MGs in our analytical framework. After that, a scanning ultrafast nanoindentation technique is used to map out the structure heterogeneity in a Zr-based bulk metallic glass (BMG). With these ongoing research efforts, we hope that more research work could be stimulated in the pursuit of the structure-property relation in MGs.

Metallic glasses (MGs) are amorphous metals lacking a long-range translational symmetry in their atomic structure. Over the past decades, MGs have been extensively studied due to their excellent mechanical and physical properties [1], [2], [3] and [4], and are therefore considered to be a candidate material for a variety of structural and functional applications [5], [6] and [7]. However, owing to the structural complexity, the deformation mechanisms in MGs have not yet been fully understood, which still remain as a topic of active research today.

In the nominal elastic regime, MGs appear to deform in the same way as traditional crystalline metals. However, the recent experiments have shown that MGs actually undergo anelastic deformation in their apparent elastic regime even at room temperature [8], [9], [10], [11], [12] and [13]. For instance, through the analysis of the X-ray diffraction results, Dmowski et al. suggested that a quarter of the apparently elastic response of an MG is indeed anelastic [8]; Ye et al. also discovered that MGs are not fully elastically loaded in this apparent elastic regime as significant mechanical hysteresis would occur if dynamic loading was exerted on MG micro-samples [9]. Since anelasticity arises as a consequence of elastic and inelastic deformation, which signals structural heterogeneity below a certain length scale, all these results thus indicate that the amorphous structure of MGs is indeed heterogeneous, namely, it comprises liquid- and solid-like regions which deform in a distinctive manner upon mechanical loading. The former acts as viscous flow units for energy dissipation while the latter as an elastic ‘scaffold’.

In the MG literature, the two widely used mean-field models for understanding the atomic-scale plastic flow in MGs, namely, the free volume [14] and shear transformation zone (STZ) model [15] and [16], were developed in the 1970s. Although these two models share a similar mathematic framework and have been successfully used to explain many important deformation features, such as shear localization or shear-band formation from the perspective of shear-induced softening/dilation [17], however, their physical basis has also been constantly debated through the comparison with the atomistic simulations and experimental results obtained recently [18] and [19].

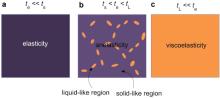

According to the STZ models [15] and [16], plastic flow occurs in MGs via the STZ event or the activation of the potential STZ site, which consists of a cluster of atoms moving collectively under shear ( Fig. 1(a)). Following the modified STZ model of Falk and Langer [16], an STZ site in MGs could be viewed as the elementary plasticity ‘carrier’ as an analog of the dislocation in a crystalline metal. Nevertheless, unlike dislocations being a structural defect that can be characterized by electron microscopy, the presence of STZs cannot be observed in advance unless they are externally perturbed. Alternatively, the atomic-scale plastic flow in MGs could be modeled following the “free volume” theory as proposed by Spaepen [14]. According to the free-volume model, plastic flow occurs via the discrete atomic jumps in and out of the free-volume site, as depicted schematically in Fig. 2(b). During this process of local diffusive jumps, free volumes could be created and annihilated, leading to the macroscopically observable plastic flow. Note that the above two kinds of models, as originally developed for yielding and plasticity in MGs, were all of a mean-field type. Therefore, any possible structural interactions were neglected. Here, the pre-yield deformation was taken as a trivial process of elasticity; yielding occurs once STZs or free-volume creation is activated without considering any non-local structural interactions.

| Fig. 1. Schematics of (a) the shear transformation zone (STZ) model, after Argon, (b) the free volume (FV) model, after Spaepen, and (c) the core-shell model proposed by us. |

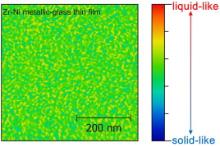

| Fig. 2. DAFM image obtained from a Zr–Ni metallic-glass thin film showing the structural contrast as determined from the ability of anelastic energy dissipation (the blue region = the solid-like region with low energy dissipation and the red region = the liquid-like region with high energy dissipation). Note that the image is adapted from Ref [26]. |

As inspired by the phenomenon of anelasticity [9] and the vast previous atomistic simulations [20], [21], [22], [23] and [24], we proposed a core-shell structural model in our previous work to rationalize the pre-yield deformation behavior of MGs [9], [25], [26] and [27]. As shown in Fig. 1(c), the atomic structure, as depicted in the core-shell model, is composed of liquid-like atoms (red spheres) and solid-like atoms (blue spheres). To retain an overall solid-like characteristic in the glass, the solid-like atoms must percolate and form an elastic network, while the liquid-like ones are therefore encaged as ‘inclusions’ or ‘flow units’. Different from the free-volume or STZ model, the core-shell model explicitly takes into account the elastic back-stress effect from the solid-like atoms, therefore explaining the anelasticity naturally [9], [25], [26], [27] and [28]. Furthermore, as all liquid-like atoms can be modeled as a liquid-like ‘phase’ interacting with its elastic ‘shell’ from a coarse-grained perspective, the core-shell model is essentially a non-local approach. From a theoretical point of view, it can be perceived that, in the ‘elastic’ regime, an existing liquid-like region may grow or reconfigure itself, or a new liquid-like region may be generated as long as the elastic ‘shell’ still remains interconnected ( Fig. 1(c)). This is a much richer picture of deformation dynamics involving structural evolution as compared to those in the original STZ or free-volume model, which is much closer to what the atomistic simulations already revealed.

To confirm the above thinking, dynamic atomic force microscopy (DAFM) was recently used to probe the surface of the metallic-glass thin films (MGTFs) [26], [29] and [30]. According to the anelastic energy dissipation measured at each individual contact between the AFM tip and the MGTF, the structural heterogeneity in MGs could be revealed. Fig. 2 shows a typical DAFM structural picture obtained from a Zr–Ni MGTF [26], from which one can clearly see a structural contrast resulting from the varying degree of anelastic energy absorption over the scanned surface. As the force exerted by the AFM tip is usually very small, we expect that the DAFM technique retains the overall feature of the atomic structure before the perturbation. In the literature, the DAFM technique was already utilized to characterize the structural heterogeneity [29] and [30] and to study the annealing-induced fractal-like densification process in the MGTF [26].

While the DAFM is a useful technique, however, it usually demands an atomic-scale surface smoothness [26] and [29], hence limiting its application to bulk metallic glasses (BMGs). Furthermore, the DAFM method is essentially an amplitude rather than force modulation technique; hence, it is very hard to quantitatively extract the local mechanical properties, such as the local modulus for the elastic ‘shell’, and the local viscosity for the viscous ‘core’. In this study, we would like to propose a nanoindentation based method to characterize the structure heterogeneity in BMGs. With a well-controlled load function, the spatial mapping of local modulus, local viscosity and local relaxation time is enabled, which provides an experimental means, alternative to the DAFM technique, in the exploration of the structure and the structure-property relation in BMGs.

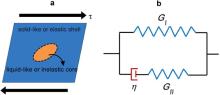

According to the core-shell model [25] and [26] ( Fig. 3(a)), the stress-induced activation of the individual viscous core is a probabilistic process. The activation probability, p, can be related to the external shear stress, τ, as follows:

where ω= the attempt frequency of the liquid-like atoms, Δ G= the energy barrier against the activation, t= the time, k= the Boltzmann constant, T= the ambient temperature, and Ω= the activation volume.

| Fig. 3. Schematics of (a) the coarse-grained core-shell model and (b) the standard linear solid (SLS) rheological model that gives rise to the same governing equation as (a). |

The total mechanical strain, γ, occurring to the MG can be approximated as the sum of the affine (elastic) strain, γe = σ/ μ, and the non-affine (inelastic) strain γi ∼ βp, where μ is the shear modulus of the solid-like shell and β is the pre-factor that quantifies the sensitivity of the total strain to its inelastic component β = ∂ γ/∂ γi. Substituting γ = τ/ μ + βp into (1) gives:

Note that Eq.(2) is a typical equation that can be derived from the standard linear solid (SLS) model in rheology, which is composed of two springs and one dashpot, as shown in Fig. 3(b). After translating the variety of physical parameters related to the liquid- and solid-like atoms into the spring moduli, GI and GII, and the dashpot viscosity η, we obtain

where α= βΩμ/( kT) can be viewed as a state variable that increases with the total volume of the liquid-like atoms in an MG. Theoretically, there are two limiting cases, i.e. α= 0 and α= infinity. The former case corresponds to an ‘ideal’ or ‘perfect’ glass without the liquid-like atoms [31], while the latter to a ‘pure’ liquid without any solid-like atoms. For these two cases, we have

Hence, anelasticity in MGs can be viewed as an intermediate case where some ‘residual liquidity’ is embedded into the ideal glass owing to the fast cooling.

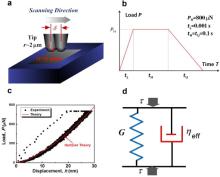

Once the theoretical basis is clear, now let us discuss how we can use the state-of-art nanoindentation technique to detect the presence of the liquid- and solid-like regions, namely, to measure the local viscosity η and the local modulus GI or GII. For this purpose, a typical Zr-based BMG with the nominal composition of Zr52.5Ti5Cu17.9Ni14.6Al10 (Vit105) was selected as the model material. Prior to indentation, the amorphous structure of the sample was confirmed by X-ray diffraction and differential scanning calorimetry [25] (not shown here) and the sample surface was mechanically polished to a mirror finish. The nanoindentation scanning of 11 × 11 points was subsequently performed on the TI 950 TriboIndenter system (Hysitron Inc., Minneapolis, MN) with a 2 μm spherical indenter at room temperature, as illustrated in Fig. 4(a). At each indentation point, we employed a load function featured with an asymmetric loading–holding–unloading profile, as shown in Fig. 4(b). In virtue of the ultrafast data acquisition capability (with a maximum of 30,000 points per second) of the nanoindentation system, unusually high loading rates could be achieved. In order to reveal the effect of anelasticity, the loading time tL, the holding time tH and unloading time tU, were both fixed at 0.001 s, 0.1 s and 0.1 s, respectively. The holding time is significantly larger than the loading time to ensure the full recovery of the anelastic deformation caused by the fast loading.

'> | Fig. 4. (a) Schematic illustration of the scanning nanoindentation test to map out the structural heterogeneity in a BMG, (b) the sketch of the indentation load function, (c) the representative nanoindentation P–h curves obtained at PH = 800 μN, showing the anelastic deformation in the Vit105 BMG. The Hertzian curve (red line) corresponds to the indenter tip radius of 2 μm, shear modulus of 30 GPa and Poisson's ratio of 0.363 for Vit105, (d) the sketch of the effective Kelvin model. |

Fig. 4(c) displays the typical load-displacement curves obtained by indenting the Zr-based BMG at a constant load of 800 μN, from which it can be seen that all curves return to the zero displacement after unloading, implicative of the elastic nature of the material's response. Furthermore, it can be seen that the loading curves deviate significantly from the Hertzian theory owing to the anelastic nature of the deformation. During the holding time, the material ‘creeps’ to the corresponding Hertzian point and then follows the Hertzian response during unloading. Note that, in a load-controlled experiment, the stress rate

where G= GIand the effective viscosity η eff= η(1 + GI/GII) = η(1 + 1/ α).

For an elastic Hertzian contact, the load-displacement relation can be expressed as

where his the indent depth; Pis the indentation load; vis the material's Poisson's ratio; Gis the material's shear modulus; and Ris the indenter tip radius. For an anelastic solid as shown in Fig. 4(d), the loading curve can be derived from the Hertzian solution using the integral transform method [32]:

where

Following the above method, the nanoindetation tests were repeated at 11 × 11 different positions in a square lattice with a spacing of 100 nm Fig. 5(a)–(c) shows the mapping of the local shear modulus, the local relaxation time and the local viscosity as obtained from the ultra-fast spherical indentation experiments. As seen in this figure, the tested amorphous structure exhibits the variations in not only the local static property, such as the shear modulus, but also the local dynamic properties, such as the local viscosity or relaxation time. Due to the limited spatial resolution (~100 nm) of the current experimental settings, a sudden or discontinuous change in these measured local properties can be witnessed. Despite that, the general trend of a local structural heterogeneity is still perceivable. Fig. 5(d)–(f) displays the statistical distributions of G, tc and ηeff, all of which can be fitted to a Gaussian curve. Again, this distribution is expected and agrees with the previous findings with respect to the distribution of local properties in MGs [20] and [33].

According to our ultra-fast indentation experiment, the typical value for the local viscosity is around 107 Pa s for the liquid-like regions in the Zr-based BMG, which corresponds to a relaxation time tc ~ 0.4 ms being encaged by an elastic ‘shell’ with a shear modulus G ~ 30 GPa. These results are consistent with the previous findings [9] and [25]. Now one may ask the following questions: (1) why do some atoms behave solid-like while others liquid-like although the atomic packing is amorphous everywhere in the glass; and (2) since the viscosity of supercooled liquids already reaches up to 1012 Pa s at the glass transition point, how come the viscosity in the glass could be such low, only around 107 Pa s?

Now let us address the first question. According to Ref. [34], glass transition can be viewed as a percolation process in which the slowly relaxing atoms, which corresponds to a large viscosity and a long relaxation time tL, percolate to form the ‘skeleton’ of the glass whilst the rapidly relaxing atoms, which corresponds to a low viscosity and a short relaxation time ts (<< tL), are therefore left as the ‘residual liquidity’ embedded in the glass. In such a case, we may term the viscosity of the percolating atoms as the global viscosity as opposed to the local viscosity of the liquid-like atoms. Given an experimental time scale te, all atoms would behave elastically if te << ts ( Fig. 6(a)). In such a case, the glass appears as a pure elastic solid. On the other hand, if ts < te << tL, structural heterogeneity can be easily detected due to the distinction between the liquid- and solid-like atoms ( Fig. 6(b)). Finally, if tL << te, all atoms appear ‘flowing’ under stress like in a liquid state, as illustrated in Fig. 6(c). According to the recent room temperature creep tests [10] and [11], we can roughly estimate that the relaxation time of the solid-like regions is about 104–105 s and the associated viscosity is about 1015–1016 Pa s when the external stress reaches about 90% of the yielding strength. According to Guan et al. [35], the viscosity and relaxation time of the solid-like regions could be even higher at a smaller stress. Because the experimental time is finite, say, te ∼ 0.2 s as in our indentation experiments, the atoms corresponding to a high viscosity or a long relaxation time (>105 s) therefore behave like elastic solids. Furthermore, the local structural motif may differ between the liquid- and solid-like atoms, which can also explain the large variation between the local and global viscosity. Following this line of reasoning, it can be understood that the viscosity measured for the supercooled liquid should correspond to the global viscosity of the whole glass while the viscosity we herein measured only should correspond to the local one. This distinction between the local and global viscosity is indeed the dynamic nature of structural heterogeneity in MGs.

To summarize, our current work can be divided into two parts. In the first part, we briefly discuss the physics and mathematical formulation of the core-shell model in comparison to the traditional free volume and STZ models. The core-shell modeling is based on the notion that there is distinction between the solid- and liquid-like atoms in the glass. As a coarse-grained approach, the core-shell model can be also applied to study the structural evolution in MGs. In the second part, we discuss the use of a nanoindentation method as in align with our core-shell model to characterize the structure heterogeneity in BMGs. Our preliminary results show that the local modulus, the local relaxation time and the local viscosity could be all mapped out simultaneously on a two-dimensional plane. This scanning ultrafast indentation method is a promising technique to characterize different amorphous structures in BMGs in terms of their local static and dynamic properties.

References

Y. Yang is grateful to the financial support provided by City University of Hong Kong (CityU) through the start-up grant for newly recruited faculty members (Project No. 7200303) and the research of C.T. Liu is also supported by CityU (Project No. CityU117612).

| 1. |

|

| 2. |

|

| 3. |

|

| 4. |

|

| 5. |

|

| 6. |

|

| 7. |

|

| 8. |

|

| 9. |

|

| 10. |

|

| 11. |

|

| 12. |

|

| 13. |

|

| 14. |

|

| 15. |

|

| 16. |

|

| 17. |

|

| 18. |

|

| 19. |

|

| 20. |

|

| 21. |

|

| 22. |

|

| 23. |

|

| 24. |

|

| 25. |

|

| 26. |

|

| 27. |

|

| 28. |

|

| 29. |

|

| 30. |

|

| 31. |

|

| 32. |

|

| 33. |

|

| 34. |

|

| 35. |

|