The cyclic extrusion compression (CEC) was applied to severely deform the as-extruded GW102K (Mg-10.0Gd-2.0Y-0.5Zr, wt%) alloy at 350, 400, and 450 °C, respectively. The microstructure, texture, and grain boundary character distribution of the CECed alloy were investigated in the present work. The mechanical properties were measured by uniaxial tension at room temperature. The crack initiation on the longitudinal section near the tensile fracture-surface was investigated by high-resolution scanning electron microscopy (SEM). The result shows that the microstructure was dramatically refined by dynamic recrystallization (DRX). The initial fiber texture was disintegrated and obviously weakened. The 8-passes/350 °C CECed alloy exhibited yield strength of 318 MPa with an elongation-to-fracture of 16.8%, increased by 41.3% and 162.5%, respectively. Moreover, the elongation-to-fracture of the 8-passes/450 °C CECed alloy significantly increased more than 3 times than that of the received alloy. The cracks were mainly initiated at twin boundaries and second phase/matrix interfaces during tensile deformation. The microstructure refinement was considered to result in the dramatically enhanced of the strength and ductility. In addition, the texture randomization during CEC is beneficial for enhancing ductility. The standard positive Hall-Petch relationships have been obtained for the CECed GW102K alloy.

Magnesium alloy is one of the lightest engineering structure materials. The high strength to weight ratio of magnesium alloy makes it extremely attractive for use in the applications requiring light weight, especially transport industry. However, the application of magnesium alloy is greatly limited by its relatively low strength and plasticity. It has been proved that microstructure refinement and texture control was an effective way to improve the ductility and strength simultaneously for Mg alloys[1].

The severe plastic deformation (SPD) method was developed to fabricate ultrafine-grained materials, by introducing a large accumulative plastic strain into the material[1, 2]. As a classic SPD method, cyclic extrusion compression (CEC) is attractive due to its characteristic of processing the relatively large bulk samples. And, CEC is very suitable for refining microstructure of hard-to-deform metals, for example, magnesium alloys, since it imposes three dimensional compression stresses during processing[1]. In recent years, CEC has been applied to refine some commercial wrought magnesium alloys, such as ZK60[1, 3], AZ31[4], AZ61 and AZ91[5]. Results show that the tensile ductility of CEC processed (CECed) alloys can be dramatically enhanced with microstructure refinement and texture evolution. However, the strength of these CECed alloys shows an unexpected decrease even though grain size was reduced effectively[6].

In recent years, the Mg-Gd-Y-Zr series alloys have attracted more and more attention due to its high strength at room temperature (RT) and great creep resistance at elevated temperature[7, 8, 9], but with a relative low ductility. The previous work[10] demonstrated that the tensile elongation of GW102K alloy can be dramatically enhanced by CEC at 450 ° C without the loss of strength. Therefore, the CEC processing could be a proper method to improve the ductility and strength of this rare-earth (RE)-containing magnesium alloy. In this study, the microstructure, texture and tensile properties of the CECed Mg-10.0Gd-2.0Y-0.5Zr alloy at different passes and temperature conditions were investigated. Based on the effects of microstructure refinement and texture weakening on the mechanical property and fracture behavior, the strengthening mechanism was discussed.

The initial material is an as-extruded GW102K alloy bar with a diameter of 30 mm. Sample pieces with a length of 42 mm and a diameter of 29.5 mm were machined, and then preheated for 0.5 h followed by CEC at 350, 400, and 450 ° C with different passes. CEC process and die structure were illustrated in our previous study[1]. The longitudinal microstructure and texture of the sample were analyzed using high-resolution scanning electron microscopy (SEM) equipped with an electron backscatter diffraction (EBSD) detector. The preparation process of EBSD samples were reported in Ref.[11]. The dog-bone specimens were machined from the CECed samples along the extrusion direction (ED) for tensile test. The tensile tests were performed using a standard universal testing machine with a strain rate of 1 × 10-3 s-1 at RT. The microstructure morphologies near fracture surface were then characterized using SEM. The samples for SEM observation were prepared using a conventional mechanical polishing technique and etched with a nitric acid (4 mL)-ethanol (96 mL) solution at RT.

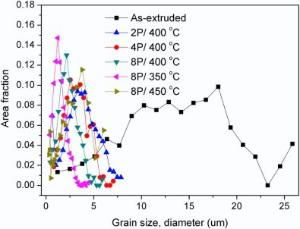

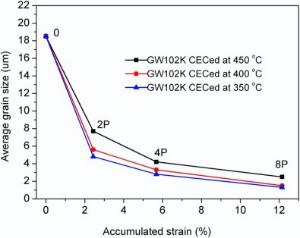

Fig. 1(a-i) shows the inverse pole figures of the as-extruded and CECed GW102K samples with various CEC pass numbers at 350, 400, and 450 ° C, respectively. The microstructures are plotted according to the stereographic triangle color scale (as shown inFig. 1(g)), i.e. the different color means different crystal direction. Fig. 2 shows the grain size distribution of the extruded and CECed samples. Result shows that the initial microstructure of as-extruded sample was non-uniform, and consists of the large equiaxed grain of ~26 µ m and a fine equiaxed grain of ~2 µ m (as shown in Fig. 1(a)). During the CEC processing, the grains were dramatically refined by dynamic recrystallization (DRX), and the second phase particles were broken into small child particles. With CEC passes increasing and temperature decreasing, totally recrystallized equiaxed grains formed, and the microstructures became more homogenous and refined. In addition, compared with the CECed ZK60 alloy[1], the much more randomly distributed grain color of CECed GW102K alloy indicate that the grain preferred orientation is not obvious.

Fig. 3 shows the grain size evolution of Mg alloys processed by CEC. It can be seen that CEC is an effective microstructure refinement way for Mg alloy. Microstructure refinement mainly occurs in the early stage of the CEC processing. With further increasing of CEC pass, the grain size refinement efficiency gradually decreased. In addition, the finer microstructures can be achieved by a lower deformation temperature. This can be attributed to a balance between recrystallization refinement and grain growth during elevated temperature CEC deformation.

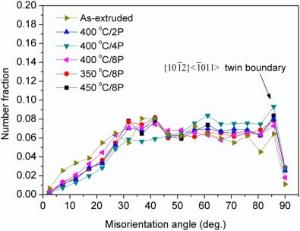

The statistics of grain boundaries misorientation angle of GW102K alloy are shown inFig. 4. Compared with the CECed ZK60[11] and AZ series alloys[5], the majority of grain boundaries of GW102K alloy were high angle grain boundaries (HAGBs) with misorientation angles lager than 15° (marked by blue lines in Fig. 1). And the fraction of HAGBs increased after CEC deformation due to almost fully recrystallized during CEC processing. With low stacking fault energy of magnesium alloy, DRX is easy to take place during the elevated temperatures CEC processing; meanwhile, low angle grain boundaries (LAGBs) and subgrain boundaries are easy to convert into HAGBs. In addition, three number fraction peaks could be distinguished around angles 35° , 60° and 86° , respectively. Its formation could be related to the deformation mechanism of magnesium, such as the {10

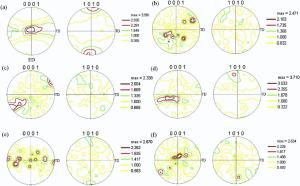

The {0002} and {10

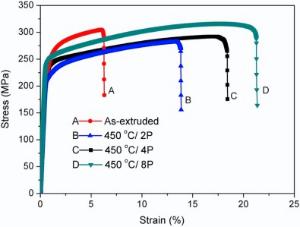

Fig. 6 presents the RT tensile engineering stress-strain curves of the as-extruded and 450 ° C CECed GW102K samples. The elongation-to-failure (δ ) of the CECed sample was drastically improved from 6.4% to 13.1% while the yield strength (YS) decreased slightly from 225 MPa to 221 MPa after 2-passes CEC processing. For the 4-passes and 8-passes CECed samples, both the elongation and yield strength were obviously increased; the results agree with those obtained in previous work[10, 17]. In addition, the strain hardening rate of the as-extruded sample was substantially higher than that of the CECed samples at low strains, which results in the strength of the as-extruded sample exceeding that of the CECed samples at a strain of 0.5%. When strained to 1%, the strain hardening rate decreased to a constant value up to failure. In addition, the long hardening regime in the CECed samples indicates that non-basal slip activities involved during the post tension test[18].

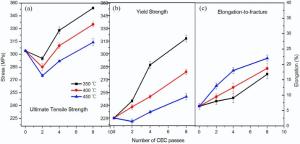

The effects of CEC deformation temperature and pass number on the YS, ultimate tensile strength (UTS) and elongation-to-fracture of the GW102K alloy are shown in Fig. 7. It shows that the CEC is an effective way to enhance the strength and the ductility of Mg alloys. Both the strength and elongation-to-fracture of the CECed samples were enhanced above 4 CEC passes at all temperatures studied in present work. The higher CEC temperature would result in the higher elongation-to-failure value but lower strength. After 8 passes of CEC at 350 ° C, the δ was dramatically increased by 162.5%, with the YS and UTS increased by 41.3% and 16.1%, respectively. Moreover, the elongation of the 8-passes/450 ° C CECed alloy significantly increased more than 3 times than that of the received sample, with the YS and UTS increased by 11.1% and 3.3%, respectively.

| Fig. 7. Effect of CEC deformation temperature and pass number on the tensile properties of GW102K alloy: (a) ultimate tensile strength; (b) yield strength; (c) elongation-to-fracture. |

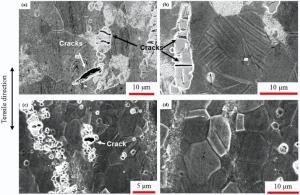

The refinement of grains and second phase particles were considered to result to the dramatic enhancement of the ductility. Fig. 8 shows the SEM morphologies of longitudinal section near the tensile fracture-surface of the as-extruded and 8-passes/450 ° C CECed GW102K alloy. As shown in Fig. 1(a) and Fig. 8(a-b), the microstructures of the as-extruded sample were characterized by a rather coarse grains and block-shape second phase. The cracks were mainly initiated at the thick-lenticular twin boundaries and brittle second phases (marked as arrow in Fig. 8(a-b)), which results in a poor elongation of as-extruded GW102K alloy. As well known, twinning is an important deformation mechanism in magnesium alloys because of an insufficient number of independent slip systems[19, 20]. For the coarse grains Mg alloys, the lower critical resolved shear stress (CRSS) of twinning compared to that of < a + c> slips gives a high propensity for the formation of twins at RT. As shown in Fig. 8, the thick-lenticular {10

| Fig. 8. SEM morphologies of longitudinal section near the failure surface of GW102K alloy: (a) and (b) as-extruded, (c) and (d) 450 ° C/8 passes CECed. |

In the present study, the dramatically enhanced strength and ductility synchronously of the CECed GW102K alloy can be attributed to the dramatically refined grains and second phase particles. The variation of the strength could be attributed to the joint effects of grain refinement strengthening and weakened texture softening. It has been proved that the mechanical properties of magnesium alloys could obviously be affected by the grains size and texture[6]. According to the well-known Hall-Petch relationship, the yield strength σ 0.2(0.2% proof stress) varies with the average grain size d as follows:

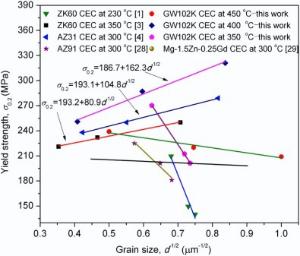

σ 0.2=σ 0+ky⋅ d-1/2

where σ 0 is a friction stress (also defined as yield stress at infinite grain size), and ky is a parameter related to the stress concentration[26, 27]. Due to the relatively high value ofky for Mg alloy, grain refinement is a much more effective method to enhance the strength of Mg alloy. However, the CECed Mg alloys often showed a decrease in yield strength even though grain size was reduced effectively[1, 3, 4, 28, 29, 30]. In this study, the YS of CECed GW102K sample was gradually enhanced with increasing the CEC deformation strain, in spite of the existence of same texture with CECed ZK60[1] and AZ31[4] alloys. Fig. 9 shows the grain size dependencies of the yield stress at 0.2% proof strain, σ 0.2, of the CECed GW102K alloy. For the purpose of comparison, the data of CECed ZK60[1, 3], AZ31[4], AZ91[28] and Mg-1.5Zn-0.25Gd[29] alloys are also presented in Fig. 9. It was noteworthy that the strength clearly corresponded to the Hall-Petch relationship for all the CECed alloys as illustrated in Fig. 9. Three Hall-Petch lines with positive slopes can be drawn for the CECed GW102K samples at different deformation temperature, which means that the YS increased gradually with the decrease of grain sizes; however, the slopes of the Hall-Petch lines of other CECed Mg alloys are negative. The variation of the relationships between yield strength and grain size of the CECed alloys could be ascribed to the combined effect of grain refinement strengthening and weakened texture softening. After CEC, the fiber texture of the as-extruded sample was changed to a new texture (as shown in Fig. 5), which is more favorable for basal slip activity and results in a decrease in the yield strength[1, 3], meaning that the texture softening overwhelms the grain refinement strengthening. The gradually decreasing yield strength of the CECed ZK60, AZ31, AZ91 and Mg-1.5Zn-0.25Gd alloys with increasing the CEC passes could attributed to the gradually decrease of texture intensity. Even with similar texture, but the intensity of CECed GW102K alloy was obviously lower than other CECed alloys, i.e., the grain refinement strengthening overwhelms the texture softening. Thus, the obvious positive slopes were observed in GW102K samples. In addition, the slopes ky of 162.3, 104.8, and 80.9 MPa µ m1/2 were obtained by linear fitting for the GW102K alloy CECed at 350, 400, and 450 ° C, respectively. The variation of slope kycould be related to the parameter of dislocation density, subgrain size, second phase particle size and volume fraction, etc.

In the present work, cyclic extrusion compression (CEC) was applied to severely deform the as-extruded Mg-10.0Gd-2.0Y-0.5Zr alloy at 350, 400, and 450 ° C, respectively. The microstructure, texture and tensile property of the CECed samples were investigated. The obtained results can be summarized as follows:

(1)The CEC processing is an efficient grain refinement way for the GW102K alloy. With CEC passes increasing and temperature decreasing, the microstructures became more homogenous and refinement. The grain refinement was mainly caused by dynamic recrystallization (DRX) during CEC deformation. The grain boundaries of CECed samples mainly composed of high angle grain boundaries (HAGBs).

(2)The initial fiber texture was disintegrated and weakened by CEC. The texture type is similar with that of CECed ZK60 and AZ series alloys, but with lower maximum texture intensity. The texture type of the CECed Mg alloy is determined by the CEC die structure, and the texture intensity is mainly depends on the alloy composition and CEC processing parameters.

(3)The yield strength, ultimate tensile strength and elongation-to-failure were simultaneous improved with the increasing of CEC passes. The elongation-to-failure of the 8-passes/450 ° C CECed alloy significantly increased more than three times compared with received alloy. The tensile cracks were mainly initiated at twin boundaries and second phase/matrix interfaces. The refinement of grain and second phase particles were considered to result in the dramatically enhanced ductility.

(4)The standard positive Hall-Petch relationships have been obtained for the CECed GW102K samples. The Hall-Petch lines slopes of 162.3, 104.8, and 80.9 MPa µ m1/2were obtained by linear fitting for the CECed samples at 350, 400, and 450 ° C, respectively. The variation of the slope could be related to the parameter of dislocation density, subgrain size, size and volume fraction of second phase particles, etc. The enhanced mechanical properties of CECed GW102K alloy could be attributed to the combined effects of microstructures refinement and texture weakening.

This work was supported by the National Natural Science Foundation of China (No.51204117); Program for the Top Young Academic Leaders of Higher Learning Institutions of Shanxi; and the Natural Science Foundation of Shanxi province (No. 2015021017).

The authors have declared that no competing interests exist.

| [1] |

|

| [2] |

|

| [3] |

|

| [4] |

|

| [5] |

|

| [6] |

|

| [7] |

|

| [8] |

|

| [9] |

|

| [10] |

|

| [11] |

|

| [12] |

|

| [13] |

|

| [14] |

|

| [15] |

|

| [16] |

|

| [17] |

|

| [18] |

|

| [19] |

|

| [20] |

|

| [21] |

|

| [22] |

|

| [23] |

|

| [24] |

|

| [25] |

|

| [26] |

|

| [27] |

|

| [28] |

|

| [29] |

|

| [30] |

|