** Corresponding author. Prof., Ph.D.; Tel.: þ86 24 23971979; Fax: þ86 24 23978883; E-mail address: ljrong@imr.ac.cn(L. Rong).

Hydrogen-induced modification in the deformation and fracture of a precipitation-hardened Fe-Ni based austenitic alloy has been investigated in the present study by means of thermal hydrogen charging experiment, tensile tests, scanning electron microscopy (SEM) and transmission electron microscopy (TEM). It is found that the γ′ particles are subjected to the multiple shearing by dislocations during plastic deformation, which promotes the occurrence of the dislocation planar slip. Moreover, the alloy will be enhanced by hydrogen resulting in the formation of strain localization at macroscale. So, the mechanisms of deformation and fracture in the alloy have been proposed in terms of serious hydrogen-induced planar slip at microscale which can lead to macroscopic strain localization.

The precipitation-hardened Fe-Ni based austenitic alloys, such as A286 (Fe-25Ni-15Cr-1.3Mo-2.1Ti-0.3Al-0.003B, wt%), are used for a variety of applications in hydrogen environment, including pumps, valves and other parts which demand higher strength. These alloys, with yield strength in range of 650-800 MPa, are strengthened by an ordered γ ′ -Ni3(Al, Ti) phase (L12 structure) coherently set in an iron-base solid solution γ -matrix. However, these alloys will not only lose about half ductility after hydrogen charging, but also exhibit a change of fracture mode from intragranular to intergranular fracture[1] [2]. Reasons for high hydrogen embrittlement (HE) sensitivity of precipitation-hardened austenitic alloys have been studied by many authors[3], [4] [5]. Although the role of second phase has been examined, such as γ ′ phase[2], eta (η )[3] and carbide[5], the mechanisms of hydrogen-induced degradation of alloys are still a subject of debate.

Concerning about failure process of hydrogen-pre-charged materials, the effect of hydrogen on the deformation and fracture behavior is important in the understanding of HE of precipitation-hardened Fe-Ni austenitic alloys. Many mechanisms proposed for hydrogen-related deformation and fracture, hydrogen-enhanced local plasticity (HELP) mechanism appear to be a viable one[6], [7], [8] [9]. The underlying principle in HELP mechanism is that reduced barriers to dislocation motion in the presence of hydrogen, thereby promoting deformation that occurs in a localized region was demonstrated by in situ transmission electron microscopy (TEM) observations[8]. Since these observations are performed at such a small size scale, it is necessary to relate them to macroscopic deformation behavior of materials.

The present investigation is mainly focused on plastic deformation and fracture process of precipitation-hardened Fe-Ni austenitic alloy before and after hydrogen charging. By probing dislocation morphology, slip traces and coarse slip bands, the study will reveal the effect of hydrogen at microscale on macroscopic behavior.

Fe-Ni based alloy was prepared in a vacuum induction furnace with the nominal compositions as follows: 30Ni-15Cr-1.3Mo-2.0Ti-0.26Al-0.3V-0.25Si-0.002B-Fe bal (wt%). The ingot was homogenized at 1433 K for 20 h, then forged and rolled into bars with a diameter of 15 mm. The samples were subjected to solution treatment at 1253 K for 1 h followed by water quenching. Then, samples were isothermally peak-aged at 1013 K for 8 h followed by air-cooling. Tensile specimens of rod and slice types were produced. The rod specimen was in a gage section of 5.0 mm in diameter and 25 mm in length and the slice specimen was in a dog-bone-shape with a width of 3 mm, a thickness of 2 mm and a gage length of 25 mm.

Hydrogen charging experiment was carried out in an autoclave with 10 MPa high-purity hydrogen, holding at 573 K for 168 h, following that tensile tests were performed immediately in air at room temperature by using a Zwick Z050 tensile machine at a strain rate of 1.33 × 10− 3 s− 1, and the average values of the mechanical properties were obtained by measuring three samples. Hydrogen-induced ductility loss can be expressed as follows:

equation(1)

LRA=(RA− HRA)/RA

where RA and RAH are area reduction of uncharged and hydrogen charged samples, respectively. The hydrogen contents in specimens after charging were about 0.0028 wt%. In order to study the slip traces before and after hydrogen charging, interrupted tensile tests to a strain of 10% were performed on each pre-polished slice tensile specimen. Then slip traces of specimen were examined by scanning electron microscopy (SEM). Thin foils specimen for TEM analysis were prepared by double-jet polishing at 253 K in 10% perchloric acid ethanol solution. Characterization of the microstructures and dislocation configuration was performed on a JEM 2100 TEM with the samples before and after hydrogen charging. Coarse slip bands on the side surfaces of fractured specimen were observed with optical microscopy (OM).

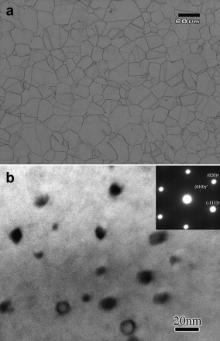

Fig. 1(a) is an optical microstructure of the aged austenitic alloy, and cellular η -Ni3Ti phase, which will result in a marked ductility loss as reported elsewhere[1]and[5], was not observed at the grain boundary. As depicted in Fig. 1(b), quite a few γ ′ particles precipitated in matrix with a size of about 10-20 nm in diameter were observed, and their diffraction pattern from [101] is presented in the right upper corner of Fig. 1(b).

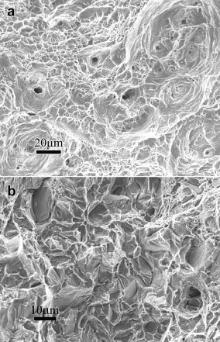

As shown in Table 1, a marked decrease in the area reduction is observed after hydrogen charging, which indicates that the notable ductility loss of the alloy should be resulted from hydrogen. Fig. 2 is tensile fracture morphology of the alloy before and after hydrogen charging, and a change of fracture mode from intragranular to intergranular fracture was observed, which is reflected in the high HE sensitivity.

| Table 1 Tensile properties and the value of RAL of the charged hydrogen samples |

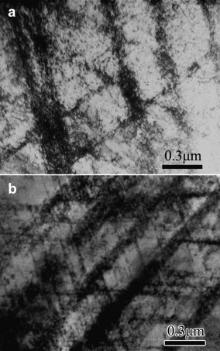

To explore the reasons for high HE sensitivity, TEM observations on hydrogen-free and pre-charged samples near fracture surface were conducted, as indicated in Fig. 3. Both non-charged and pre-charged specimens exhibit the similar types of dislocation configuration, except for a more distinct planar feature in the latter case (Fig. 3(b)), namely, planar slip of dislocations in the alloy has been promoted by hydrogen, just as reported in pure aluminum by Ferreira et al.[8] and in iron single crystal by Hwang and Bernstein[10].

Fig. 4 (a) is the SEM image of slip band and γ ′ precipitates near the fracture in the pre-charged specimen and its magnified micrograph is shown in Fig. 4(b). A lot of γ ′ particles are observed in the slip bands and some sheared γ ′ particles are identified correspondingly, as depicted in Fig. 4(c). Compared with the morphology of γ ′ particles in the non-deformed specimen (Fig. 1(b)), a fact can be declared that they have been subjected to the multiple shearing by dislocations during plastic deformation because of their ordered atomic structure.

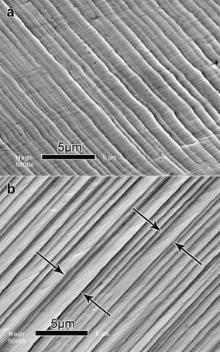

For the non-charged and pre-charged specimens loaded to plastic strain of 10%, their surface slip traces are illustrated in Fig. 5. By comparing their differences, two interesting features can easily be found. One is that the slip lines are clearly much straight in the pre-charged specimen compared with that of the uncharged specimens, and similar phenomena have also been observed by other researchers[11] and [12]. Note that these results of slip traces are the expected ones which provide an indication of increased planar slip of dislocations after hydrogen charging and are in a good consistent with the observations of dislocation morphology in Fig. 3. The other is that some coarse slip traces with increased spacing are observed after hydrogen charging (shown by arrows in Fig. 5(b)), which implies that hydrogen-induced heterogeneous slip occurs in pre-charged specimen. Also, similar behaviors, named as strain localization, were found in some single-phase austenitic steel such as 310S[13] and 316L[14]. For example, on the basis of fractography and slip trace, Abraham and Altstetter[13] proposed that hydrogen promotes slip localization evidenced by increased slip step heights and more intergranular facets. Yagodzinsky et al.[14] studied the effect of hydrogen on deformation of single crystal austenitic stainless steel, and found that hydrogen enhanced strain localization in the form of shorter and more grouped slip lines, in contrast to uniform ones in an uncharged alloy.

| Fig. 5 SEM images of slip traces of experimental specimens loaded to 10% plastic strain: (a) without hydrogen, (b) with hydrogen. |

Optical micrographs of slip bands near the fracture for the uncharged and pre-charged specimens are depicted in Fig. 6. For the uncharged specimen, much heterogeneous deformation occurs by formation of some coarse slip bands within a small region near fracture surface (Fig. 6(a)). These coarse slip bands typically carry more strains than fine slip bands far away from fracture and are believed to be preferred sites for macroscopic localized shear fracture of alloy[15]. In contrast to the uncharged specimen, the charged one exhibits a different feature, and few coarse slip bands were observed. Instead, there are occasionally some fine grain-scale slip bands as shown by white arrow in Fig. 6(b). In addition, Fig. 6(b) also illustrates large cavities ahead of crack tip (marked with black arrow), indicating that fracture initiates and grows along a principle coarse slip band. This provides a strong evidence of the hydrogen-induced shear localization in pre-charged specimen.

While it is generally agreed that hydrogen promotes planar slip of dislocations at microscale, the possibility that it can in turn lead to a significant degradation in ductility is still unclear. It is required to demonstrate the relationship between dislocation morphology at microscale and macroscopic failure process. So, several results in present study are not worthy and deserve discussion.

As mentioned in Section 3, the presence of hydrogen will promote plastic strain localization in precipitation-hardened Fe-Ni based austenitic alloys. Although the exact mechanism of strain localization by hydrogen is still unclear, it has been suggested that strain localization can be resulted from a sudden increase in mobile dislocation density within localized deformation bands[16]. In precipitation-hardened Fe-Ni based alloy, since the effective cross section of the γ ′ particles is successively reduced after shearing of the particles observed in our previous study[17], the critical shear stress for the dislocations to cut through the particles in an already activated slip plane is lower than others. As a result, slip concentrated on local few slip planes is induced (Fig. 3(a)). At the same time, as shown in Fig. 3(b), planar slip of dislocations has been promoted by hydrogen, which will result in increased mobile dislocation density within localized deformation bands. Therefore, the hydrogen-induced strain localization is probably due to serious slip planarity induced by the combination of effect of shearing γ ′ particles and hydrogen.

It is well known that shear localization, where plastic flow is concentrated in thin bands, is one of the most common types of non-uniform deformation modes. A homogeneous deformation field often gives way to shear localized deformation. Price and Kelly[18] proposed that shear fracture is initiated by characteristic coarse slip bands. As stated by Gilman[19] and Harren et al.[20], these bands are natural outcomes of the dislocation slip which makes plastic flow fundamentally inhomogeneous, and factors that influence dislocation mobility are recognized as primary factors controlling characterization of bands. In some precipitation-hardened alloys, such as Al-Cu[21] and Al-Li[22], the coarse slip bands occur easily because of particle cutting. Occurrence of the localized deformation within shear bands is unexpectable because it will decrease the ductility of alloy, just as observed in precipitation-hardened Al-Cu alloy[21]. Note that this behavior mentioned above is associated with the bands forming abruptly and ductility loss.

In the present study, the planar slip of dislocations becomes more distinct after hydrogen charging and deformation is much more localized. A critical fracture strain will be rapidly exceeded in one of coarse slip bands, and crack formation will start early along the slip band that leads to the loss of load bearing capacity, which is manifested by highly localized macroscopic rupture initiated by principle coarse slip in the hydrogen-charged alloy, just as theoretical interpretations by Liang et al.[23].

(1) At microscale, the γ ′ particles have been subjected to the multiple shearing by dislocations during plastic deformation in the Fe-Ni based austenitic alloy, which promotes the occurrence of the dislocation planar slip, and it will be enhanced by hydrogen.

(2) At macroscale, serious dislocation planar slip results in the formation of the strain localization in the alloy after hydrogen charging.

(3) Under the combination of effect of shearing γ ′ particles and hydrogen, serious dislocation planar slip occurs at microscale and results in formation of strain localization at macroscale, which is the main reason for high HE sensitivity in the precipitation-hardened Fe-Ni based austenitic alloy.

The authors have declared that no competing interests exist.

| [1] |

|

| [2] |

|

| [3] |

|

| [4] |

|

| [5] |

|

| [6] |

|

| [7] |

|

| [8] |

|

| [9] |

|

| [10] |

|

| [11] |

|

| [12] |

|

| [13] |

|

| [14] |

|

| [15] |

|

| [16] |

|

| [17] |

|

| [18] |

|

| [19] |

|

| [20] |

|

| [21] |

|

| [22] |

|

| [23] |

|