The microstructure and mechanical properties of newly developed Al-35Zn cast alloys with TiB refiner addition were evaluated by X-ray diffractometry, optical microscopy, and scanning electron microscopy coupled with energy dispersive spectrometry. The microstructure of these alloys featured α-Al dendrites surrounded by Al-Zn (α + η) eutectic structures. After the addition of TiB refiner, the alloy grain sizes decreased, and its morphology abruptly changed from dendritic to equiaxed grains. Such an improved microstructure of the modified alloys was accompanied by a significant increase in the tensile strength and elongation percentage compared to those of the Al-Zn or Zn-Al-based alloys. The results showed that with the increase of TiB content up to 0.05%, the morphology of α-Al dendrites and α + η phases changed from coarse dendrite and lamellar structures into independent and fine ones. Based on these results, the effect of TiB refiner addition on the microstructure and mechanical properties of the Al-35Zn binary alloys was investigated.

Al-Si cast alloys are common casting alloys that exhibit excellent specific strength, good castability, and high corrosion resistance[1, 2, 3]. Thus, they are widely utilized in manufacturing lightweight Al alloys. Despite these advantages, Al-Si cast alloys are characterized by poor mechanical properties because of the brittleness of the Si phase. An additional T6 heat treatment of the alloys after casting does not raise their strength to the required level of 320 MPa, while extra post-treatment procedures only increase unit costs[4]. Therefore, the Al-Si alloys cannot be used for producing high-strength structural materials with good toughness. However, castings with excellent mechanical properties obtained by modifications of wrought aluminum alloys have recently attracted significant interest[5, 6]. Compared to other cast alloys, the Al wrought alloys characterized by high melting temperatures, low fluidity, and extensive solidification ranges, which easily produce various defects, such as hot tears, and result in shrinkage or the presence of intermixed gases. However, the Al-Zn-based alloys recently developed by Shin et al. not only exhibited very good mechanical properties and fluidity, but was also characterized by a low melting point. Thus, the addition of large amounts of Zn can effectively lower the melting point of the alloys and improve their fluidity[7]. When a small amount of Cu was added to an Al-Zn alloy, superior mechanical properties were achieved. This result may enable high strength Al-35Zn and Al-Zn-Cu alloys[8], which have been developed as substitutes for cast iron, to be produced for use as bearing caps in the crankcases of internal combustion engines.

According to the Al-Zn phase diagram[9], the solubility of Zn in Al is very high, and a lamellar structure is formed after the α -Al and η -Zn phases are solidified at the grain boundary regions between the α -Al grains. These structures are obtained from a monotectic reaction that is similar to the eutectic reaction (L1 = α + L2 designates the reaction that generates liquid and solid solution phases from a single liquid phase). This solidification type makes such alloys suitable for producing special bearing and abrasive materials. In addition, the Al-Zn alloys possess excellent castability, high fluidity, and good wear resistance, while their formation requires relatively low energy. Because of these properties, Al-Zn alloys have been utilized for manufacturing various engineering components and certain friction materials[10, 11]. For instance, Alemdag and Savaskankan added a maximum amount of 40% Al to Zn, making an alloy that exhibited excellent mechanical properties and high wear resistance[12]. The results indicate that large amounts of Zn mixed with Al produce particularly fine structures because of the monotectic reaction, improving the mechanical properties of the material because of the refinement of the Al phase. In general, the formation of fine grains through heterogeneous nucleation has been considered as the two main grain refinement mechanisms[13, 14, 15]. A rapid quenching technique is a relatively easy method to obtain the grain refinement, but it is difficult to control the cooling rate. In some previous studies, Zr[16] and Ti[17] were used as main refiners to reduce the Al grain sizes, with Ti being more effective than Zr for this purpose[18, 19].

In this work, Al-35Zn alloys containing small amounts of 0.01%-0.1% TiB were prepared. The primary α -Al phase and α + η lamellar structure of the Zn-rich grain boundary regions were simultaneously refined by the addition of TiB, changing the mechanical properties of the alloy. The Al-35Zn alloys exhibited excellent mechanical properties characterized by elongations greater than 13.8% and a tensile strength of 380 MPa without additional heat treatment after casting. Based on these results, the effects of TiB addition on the microstructure and mechanical properties of the Al-35Zn binary alloys were investigated.

A binary alloy containing Al 65% and Zn 35% was used in this study. It was produced by melting a mixture of 99.8% pure Al with 99.95% pure Zn at 750 ° C, while gases were removed from the melt by nitrogen bubbling at 720 ° C. Next, the molten metal was stabilized by holding at 700 ° C for 10 min and refined by adding different amounts of TiB (Al-5%Ti-1%B) to give a final content ranging from 0.01% to 0.10% at the same temperature. The resulting alloys were poured into pre-heated (at 150 ° C) permanent molds with dimensions of W 39 mm × L 33 mm × H 190 mm. We conducted chemical composition analysis of the prepared Al-35Zn alloy as a function of TiB refiner content by using inductively coupled plasma-atomic emission spectroscopy (ICP-AES, SP51550, Seiko), as shown in Table 1.

| Table 1. Chemical composition (wt%) of the Al-35Zn alloys with 0-0.1% TiB refiner contents as determined by ICP-AES |

To observe the changes in the α -Al phase caused by the addition of various TiB amounts, a cross-section of the tensile test specimen was processed by cutting, followed by polishing to a mirror finish, and then etching in Keller's solution (175 mL distilled water + 20 mL NHO3 + 3 mL HCl + 2 mL HF). The microstructures were then studied with an optical microscope (Nikon, ECLIPSE MA200) and a scanning electron microscope (SEM, Carl Zeiss Supra 40). Energy-dispersive spectrometry (EDS) and field emission scanning electron microscopy (FE-SEM) were used to analyze the composition and phases of the alloys. The average α -Al phase size (grain size) was determined by electron backscattering diffraction (EBSD; S-4300, Hitachi) at a scanning step size of 0.7 µ m. The EBSD results were processed using orientation imaging microscopy analysis software (TSL-OIM, EDAX); the data points with a confidence index below 0.1 were removed from the EBSD data. To observe the phase distribution and formation of intermetallic compounds, an XRD analysis (CuKα , Rigaku-D/MAX 2500-V/PC) was performed.

Tensile tests were conducted to evaluate the mechanical properties of the alloys. The tensile test specimens were produced in accordance with the ASTM 370-05 test requirements. The tensile tests were performed at room temperature (about 15 ° C) using an Instron-5989 tester at a constant cross-head speed of 1 mm/min. Non-contacting advanced video extensometers (AVE) of the tester were utilized to measure specimen elongations. The hardness of the Al-35Zn alloys as a function of TiB refiner was determined using a Vickers hardness tester (HM-122, Akashi, Japan) with a diamond indenter at a load of 50 gf.

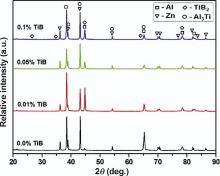

Fig. 1 shows the XRD patterns of the Al-35Zn alloys containing 0-0.1% of TiB, which consist of the α -Al phase, η -Zn phase, TiB2 and Al3Ti intermetallic compounds. The XRD results reveal that diffraction patterns of the alloys without and with TiB resemble, but different peak intensities are found at 2θ values of about 45○, 65○ and 78○. Thus, the TiB refiner addition to the Al-Zn alloy generates heterogeneous nucleation sites. Meanwhile, an Al-Ti-B master alloy is widely used as a grain refiner for Al alloys, and most of the B phase exists in the form of TiB2[20] or (Al1-xTix)B2[21], and the excess Ti exists as TiB2, but Ti presents as a single form in the molten metal because of its dissociation at elevated temperatures. When the Al-Ti-B master alloy was added to Al molten alloy, the excess Ti created the Al3Ti layers, which environ the TiB2 particles in the alloy, resulting in the refinement of α -Al grain. Because of the excess Ti in the molten alloy, TiB2 and TiAl3 core-shell structures are formed [22, 23, 24, 25], which are most likely related to the grain refinement. As indicated by the XRD patterns, the main crystal phase includes the α -Al-rich phase and the η -Zn-rich phase, which co-exist as a single phase, while no diffraction peaks corresponding to the Ti single phase were observed. However, both the TiB2 and Al3Ti were detected by XRD technique. According to these results, the TiB2 and Al3Ti phases heterogeneously nucleated in the Al-Zn binary alloy and refined the primary α -Al phase.

The XRD analysis reveals that the consequence of adding TiB refiner to the Al-35Zn binary alloy was the formation of TiB2 and Al3Ti phase. XRD, optical microscopy, EBSD, SEM, and EDS techniques investigated the morphology and distribution of each phase as functions of TiB content. The optical micrographs depicted in Fig. 2(a)-(d) and the EBSD micrographs in Fig. 2(e)-(h) display the size and distribution of grains for the gravity cast Al-35Zn alloys containing 0-0.1% of the TiB refiners. Fig. 2(a) shows the typically big scale dendrite morphology of the α -Al grain in the Al-35Zn alloy. In contrast, the grain boundary region is composed of the non-equilibrium solidification phases or Zn-rich phase, which issurrounded by the α -Al phase. Fig. 2(b)-(d) shows the effect of TiB refiner addition resulting in a refined dendrite α phase with microstructures that are completely different from those observed in Fig. 2(a). In addition, the morphology of the refined α -Al phase changes from dendritic to equiaxed grains as the amount of the added TiB increases, and the average grain size of the alloys was estimated by using EBSD. The EBSD micrographs represented in Fig. 2(e)-(h) shows the size and distribution of the grains of the Al-35Zn alloys with TiB refiner content. The average α -Al grain size for the Al-35Zn alloy decreases from 148 to 27 µ m, as shown in Table 2. As the TiB refiner content increases, the alloy morphology changes from dendrite to equiaxed grains because of the heterogeneous nucleation.

| Table 2. Average α -Al grain size estimated by EBSD for the Al-35Zn alloys with 0-0.1% TiB refiner contents |

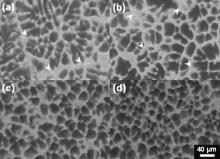

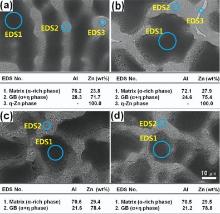

In order to study the morphology of the Zn-rich grain boundary regions in more detail, the corresponding SEM images were obtained, while the EDS was used to analyze each phase composition. The results are represented in Fig. 3 and Fig. 4. As shown in Fig. 3, grains refinement through spheroidization was observed with increasing TiB refiner content. Fig. 3(a) exhibits typical dendrite morphology. The dark areas in each figure denote the α -Al phase; the bright areas correspond to the Zn-rich grain boundary regions with the Al-Zn lamellar structure (α + η ); and the lightest areas (indicated by arrows) observed in Fig. 3(a) and (b) are assumed to be the Zn (η ) phase. Hence, the developed Al-Zn35 alloys contain three main phases. When the Al-based alloy contains a large amount of Zn, a microstructure is formed through a monotectic reaction[26] (L1 = α + L2); thus, the solidification is characterized by (1) primary α phase crystallization + L2 creation, and (2) an L2 = rich Zn phase + Al (α + η lamellar structure) phase, where the η -Zn phase is observed on the grain boundaries. The η -Zn phase is a brightest phase on the grain boundary regions, as shown in Fig. 3(a) and (b), corresponding to the Zn-rich phase disappearing with high content of TiB refiner. It is evident that there is refinement of the primary α -Al phase with 0.05% and 0.1% TiB refiner additions to Al-35Zn alloy, as shown in Fig. 3(c) and (d). To interpret these results, an EDS analysis was performed by focusing the electron beam on each phase, including the Zn-rich grain boundary regions and the lightest phase region, as shown in Fig. 4.

| Fig. 3. SEM images for the Al-35Zn cast alloys with (a) 0.0, (b) 0.01, (c) 0.05, and (d) 0.1% TiB refiner contents. Arrows point to the 100% Zn phase (in 3% HF solution). |

| Fig. 4. SEM and EDS results for the Al-35Zn cast alloys with (a) 0.0, (b) 0.01, (c) 0.05, and (d) 0.1 wt% TiB refiner contents. |

Fig. 4 shows the EDS analysis results for the Al-35Zn alloys with TiB refiner additions. The α -Al phase contains Zn, as shown in Fig. 4 (EDS No. 1). The size of the Al-Zn (α + η ) eutectic structures and the Zn composition increased with increasing TiB refiner content. The EDS results indicate that the bright phase, which partially exists in the grain boundary regions, consists of 100% Zn, as shown in Fig. 4(a) and (b). When the Al-35Zn alloy begins to solidify, the primary α phase initially crystallizes from the melt. At 443 ° C, the remaining melt and α -phase crystalline transform to the β phase according to the peritectic reaction L + α → β , while the originally formed α phase and the newly formed β phase constitute the matrix grain. Then, the eutectic reaction L → β + η occurs at 382 ° C, and the eutectic β + η structure appears in the remaining liquid with a high Zn content. The grain boundary region of the Al-35Zn alloy was formed by the creation of the β + η phase. The final microstructure formed by the eutectoid reaction β → α + η at 275 ° C resulted in the formation of the η -Zn phase. Meanwhile, the Al-Zn alloy was refined by heterogeneous nucleation due to the addition of the TiB refiner, as the above-mentioned various reactions would occur more effectively. As a result, the grain boundary regions consisting of α + η phase increased by employing the pure η -Zn phase to the formation of α + η phases. These observations were confirmed by the decrease in pure η -Zn phase, which was not detected in Fig. 4(c) and (d). Therefore, the microstructure of the grain boundary regions was changed by the addition of TiB refiner.

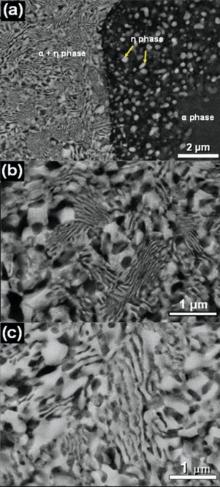

Fig. 5(a) presents the high-resolution SEM image of the grain boundary regions of the Al-35Zn gravity-cast alloy with 0.01% TiB addition, showing a fine α + η lamellar structure. A η -Zn containing region was observed near the α -Al grain outside, where the rapid cooling rate was expected to form other fine lamellar structures inside the grain boundary regions.Fig. 5(b) and (c) show the magnified images of α + η phases with spacing of 120 nm or less in the grain boundary regions of the 0.05% and 0.1% TiB addition alloy, respectively. Considering that the typical interlamellar spacing between fine phases normally ranges from 160 to 500 nm[27], the microstructures with the interlamellar spacing of approximately 120 nm obtained for this alloy correspond to very fine structures. These fine α + η lamellar structure can have pinning effect on dislocation and dislocation from movements, resulting in improving the tensile properties of the alloy[28, 29]. However, interlamellar spacing and the fraction of the η -Zn phase changed due to increasing TiB refiner content. This result indicates that the excess Zn contributes to the formation of α + η lamellar structure of the grain boundary regions, and as a result the fraction of the η -Zn rich grain boundary regions increases significantly, while the α -Al grain size decreases. To summarize the obtained data, the fraction of the grain boundary region increased due to TiB refiner adding, which in turn results in the heterogeneous nucleation and the formation of the refined α -Al phase with extended grain boundary regions corresponding to the α + η phase. As a result, it is expected to change the mechanical properties of the alloy.

We measured the hardness of the Al-35Zn alloy as a function of TiB refiners by using a Vickers hardness tester. The Al-35Zn alloy without TiB refiner exhibits an average Vickers hardness value of 118. The addition of 0.01% TiB to Al-35Zn alloy increases the hardness to 126. When the TiB refiner content increases up to 0.05%, the hardness increases to 135. However, increasing the TiB content beyond 0.05% results in slightly decreasing the Vickers hardness value. Overall, the Vickers hardness of the Al-35Zn alloys increases with increasing TiB refiner content in this study. Therefore, increasing the TiB refiner content was considered to improve the yield strength of the alloy.

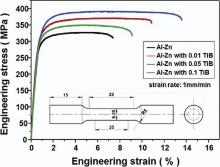

The yield strength, ultimate tensile strength and percentage elongation value of the alloys with and without TiB refiner additions are presented in Table 3. It is evident that TiB refiner additions improved both strength and elongation values of the alloy. The yield strength and UTS are increased from 268 to 343 MPa and from 322 to 383 MPa, respectively. The elongation percentage improved from 7.3% to 13.8%. Among the TiB refiner containing Al-35Zn alloy, the alloy added with 0.05% TiB refiner shows the best yield strength, UTS and elongation, as shown in Fig. 6. It can be attributed to the influence of TiB refiner addition on refining the α -Al grain and α + η lamellar phases in the grain boundary regions. As mention before, fine microstructures promote the pinning effect on dislocation and dislocation from movements, resulting in improving the mechanical properties of the alloy. The presence of refined α -Al grain with a non-continuous network and refined lamellar phases possibly prevents the initiation and propagation of cracks and leads to a positive effect on the strength and ductility. It should be noted that refined Al-35Zn alloys with high TiB content (0.1%) have lower strength and ductility, in comparison with Al-35Zn alloys containing lower TiB refiner content (0.01% and 0.05%). This can be attributed to the increasing interlamellar spacing of α + η phase and fraction of grain boundary regions, as shown in Fig. 5. Accordingly, the mechanical properties of the Al-35Zn alloys with high TiB refiner decreased.

| Table 3. Yield strength, ultimate tensile strength and elongation values of the Al-35Zn alloys with TiB refiner addition |

In this study, the average α -Al grain size for the Al-35Zn alloy decreases from 148 to 27 µ m as a function of TiB refiner content. It is well known that a decrease in the grain size helps to improve the yield strength of an alloy, as defined by the Hall-Petch equation[30]. Therefore, the Al-35Zn alloys can be strengthened by grain size reduction caused by TiB refiner addition. Since Al and Zn do not combine to form an intermetallic compound[8], even with the addition of a relatively large amount of Zn, a fragile secondary phase will not form in the Al-Zn system. Therefore, this alloy system is not considered for the work hardening, as shown in Fig. 6. However, Al-35Zn alloys show high ductility, which is caused by the fine α -Al grain size and α + η phase lamellar structure via TiB refiner addition. Besides, developed alloy has not occurred by local deformation, namely that stress concentration region is not formed because the secondary phase or reinforcing phase does not exist in Al-35Zn alloy. As a result, this alloy exhibits high ductility by uniform deformation.

The Al-35Zn alloys produced in this study show excellent tensile properties after the addition of TiB. In particular, the plastic deformation of this alloy is associated with the creation of shear bands and the generation/propagation of cracks. Fig. 7 shows the optical and SEM images obtained from the side surfaces of the fractured Al-35Zn alloy tensile specimen with 0.05% TiB refiner addition. A uniformly plastic deformation in the entire sample is consistent with the high ductility of refined Al-35Zn alloy, as shown in Fig. 7(a). In addition, Fig. 7(b) shows the SEM fractograph recorded from the regions near the fracture tensile-test sample and indicates the formation of 45° shear bands across the all-around sample. These observed shear bands are not connected mutually, which contributes to the high ductility of the alloy.

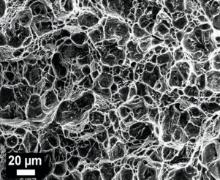

Considering the high elongation and tensile strength of the alloy refined by TiB addition, the fracture mechanism was based on ductile fracture. Fig. 8 shows the fracture surface of the 0.05% TiB-refined sample. It is evident from Fig. 8 that the fracture features showed by the sample containing TiB refiner have ductile behavior. In addition, the surface morphology of the specimen shows a large number of slips and shear deformation, which indicates that the alloy was fractured by a uniform deformation. Furthermore, the observed plastic deformation corresponds to a very high elongation value of the 0.05% TiB-refined alloy. As shown in Fig. 8, a large number of dimples were created inside the Al-35Zn alloy with 0.05% TiB refiner and were found that the whole fracture surface is entirely covered by dimples with sizes less than 25 µ m.

| Fig. 8. Secondary electron micrographs recorded for the fracture surface of the Al-35Zn alloy with 0.05% TiB refiner content showing the presence of multiple dimples with sizes less than 25 µ m. |

Higher content of grain refiners may increase hot tear susceptibility because they tend to agglomerate near grain boundaries. This is especially true for inactive insoluble particles such as TiB2, which can be clustered by solid-liquid interface movements during solidification. In general, the content of Ti should be less than 0.15% in order to refine the Al cast alloy. Owing to recombination and coagulation of the Ti[31, 32], higher Ti content may affect Al alloy to increase sensitivity to hot tear, as well as coarse Ti-related phase can promote stress concentration. However, since the TiB content was less than 0.15%, the aggregation probability was reduced, while in this study TiB refiner content less than 0.1% was employed, and as a result it is possible to avoid the aforementioned negative effect for Al alloy casting defect.

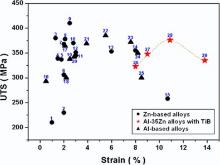

In this study, the Al-35Zn alloy with 0.05% TiB refiner exhibited, even without the T6 heat treatment process, higher mechanical property than those of Al- and Zn-based alloys. Fig. 9shows the UTS versus elongation values for the refined Al-35Zn alloys with ternary and quaternary Al- and Zn-based alloys. Moreover, we investigated the specific strength of the Al-35Zn alloy compared with commercially ADC12 alloy[43] produced by the gravity casting condition: Al-35Zn alloy-UTS: 380 MPa, ρ : 3.45 and specific strength: 110 MPa, and commercially ADC12 alloy-UTS 240 MPa, ρ : 2.8 and specific strength: 85.7 MPa. Despite being not lightweight due to high content of Zn, Al-35Zn alloy shows excellent specific strength. Thus, refined Al-35Zn alloy can be applied to various industrial fields.

| Fig. 9. Ultimate tensile strengths (MPa) vs. elongation (%) of various Al-Zn or Zn-Al based alloys. 1 Zn-4Al-1Cu[33], 2 ZA8[34], 3 Zn-40Al-2Cu-2.5Si[35], 4 Zn-40Al-2Cu-1Si[36], 5 Zn-27Al-2Cu-1Si[36], 6 Zn-27Al-2Cu[36], 7 Zn-40Al-4Cu[37], 8 Zn-40Al-2Cu-2Si[36], 9 ZA27[38], 10 Zn-40Al-3Cu[37], 11 ZA12[34], 12 Zn-40Al-2Cu[37], 13 Zn-40Al-1Cu[37], 14 ZA27+Zircon[39], 15 ZnAl4Y-0.5TiB[40], 16 Al-Zn-Mg-Ce[41], 17 Al-40Zn-5Cu[12], 18 Al-40Zn-3Cu-3Ni[42], 19 Al-40Zn-3Cu-2Ni[42], 20 Al-40Zn-3Cu-1Ni[42], 21 Al-40Zn-4Cu[12], 22 Al-40Zn-3Cu[12], 23 Al-40Zn-2Cu[12], 24 Al-40Zn-1Cu[12], 25 Al-40Zn[12], 26 Al-35Zn-based alloy, 27 Al-35Zn-0.01% TiB alloy, 28 Al-35Zn-0.05% TiB alloy, 29 Al-35Zn-0.1% TiB alloy. |

(1) With the increase of TiB refiner content, the a-Al phase morphology noticeably changed from dendritic to equiaxed grains that are decreased from 148 to 27 µ m.

(2) The heterogeneous nucleation of the TiB2 and Al3Ti phases in binary alloys leads to a refinement of the α -Al phase.

(3) In the presence of 0.01%-0.1% TiB refiner, the strength and elongation of the Al-35Zn binary alloy were improved. Among the TiB refiner containing Al-35Zn alloys, the sample with added 0.05% TiB refiner exhibits the best mechanical properties.

(4) The excellent mechanical properties of the newly developed Al-35Zn alloys result from the micro-sized α -Al phase and very fine lamellar structures (α + η phase) formed by the TiB refiner addition.

(5) The Al-35Zn alloys with 0.05% TiB refiner exhibit excellent mechanical properties without additional T6 aging treatment after casting.

The 2015 National Research Laboratory Program and grant-in-aid program of the National Core Research Center provided by the Korea Ministry of Science and Technology and the Korea Science and Engineering Foundation (No. 2013M3A6B107889) supported this study.

The authors have declared that no competing interests exist.

| [1] |

|

| [2] |

|

| [3] |

|

| [4] |

|

| [5] |

|

| [6] |

|

| [7] |

|

| [8] |

|

| [9] |

|

| [10] |

|

| [11] |

|

| [12] |

|

| [13] |

|

| [14] |

|

| [15] |

|

| [16] |

|

| [17] |

|

| [18] |

|

| [19] |

|

| [20] |

|

| [21] |

|

| [22] |

|

| [23] |

|

| [24] |

|

| [25] |

|

| [26] |

|

| [27] |

|

| [28] |

|

| [29] |

|

| [30] |

|

| [31] |

|

| [32] |

|

| [33] |

|

| [34] |

|

| [35] |

|

| [36] |

|

| [37] |

|

| [38] |

|

| [39] |

|

| [40] |

|

| [41] |

|

| [42] |

|

| [43] |

|