To enhance the fracture toughness of pressureless-sintered SiC ceramic, graphene was introduced as an additive. The effects of graphene contents on the fracture toughness, bending strength, micro-hardness, phase compositions, and microstructure evolutions of the SiC ceramics were investigated in detail by scanning electron microscopy, energy dispersive X-ray spectroscopy, and metallographic microscopy. The fracture toughness, bending strength and micro-hardness increased initially, and then decreased with the graphene content increasing from 0 to 5.0 wt%. The highest fracture toughness of 5.65 MPa m1/2 was obtained for sample with 1.0 wt% graphene sintered at 2130 °C for 1 h in Ar, which was about 22.6% higher than that of SiC sample without graphene. In addition, the highest bending strength and micro-hardness of 434.14 MPa and 29.21 GPa corresponded to the SiC samples with graphene content of 0.5 wt% and 2.0 wt%, respectively.

As a structural and functional ceramic, silicon carbide (SiC) offers many advantages, including high melting temperature, high elastic modulus, low density, excellent thermo-stability and corrosive resistance in severe environments, sufficient thermal conductivity, excellent creep, wear and oxidation resistance, and good mechanical properties retention to high temperature, etc. The combination of properties makes SiC a promising candidate applications, such as ceramic engine components, refractories, wear-resistance tools, heat exchangers, and electronic substrates[1, 2, 3, 4, 5, 6, 7]. Solid-state pressureless-sintered SiC using boron and carbon as sintering aids exhibits excellent corrosion resistance, good strength, and high hardness from room temperature to elevated temperatures[8]. However, its fracture toughness is relatively low due to substantial transgranular fracture mode, which hinders its practical applications.

Numerous researchers studied SiC ceramics fabricated by liquid-phase-sintered (LPS) method by adding some oxide additives, such as R2O3 (R = Al, Y, Gd, Ho, Lu, etc.) [9, 10, 11, 12, 13]. And LPS-SiC ceramics indeed possessed excellent mechanical properties, especially at room temperature. However, the liquid phases could degrade the bending strength at high temperatures (above 1400 ° C) because of the formation of glassy grain boundary phases[14].

Graphene is a planar monolayer of carbon atoms arranged into a two-dimensional honeycomb lattice with a carbon-carbon bond length of 0.142 nm[15], which demonstrates a variety of intriguing properties, including superior mechanical properties (Young's modulus of 1 TPa and tensile strength of 130 GPa)[16], high electron mobility at room temperature (15 000 cm2/(V⋅ s))[17], and exceptional thermal conductivity (~5000 W/(m⋅ K))[18]. In addition, researchers[19, 20, 21] have reported the growth of graphene on the single-crystal SiC by thermal decomposition. Thus, it can be inferred that the graphene might be well compatible with SiC, and adding graphene into SiC ceramics is expected to achieve SiC ceramics with good mechanical properties at both room temperature and high temperatures. Asl and Kakroudi[22] investigated the effects of graphene on the fracture toughness of ZrB2-25 vol.% SiC composite fabricated by hot pressing method, and the results showed that the fracture toughness increased considerably for the composite with 5 wt% graphene. Romá n-Manso et al.[23] studied the effects of graphene on the electrical conductivity of SiC ceramics fabricated by liquid-phase spark plasma sintering method. They found that the electrical conductivity increased up to three orders of magnitude at room temperature for materials with 20 vol.% graphene. However, for pressureless-sintered SiC ceramic, there were few reports regarding the effect of graphene on mechanical properties of SiC, such as bending strength, fracture toughness, hardness, etc.

In this study, SiC ceramics with different graphene contents using B4C and C as sintering aids were fabricated by solid-state pressureless-sintered method. The effects of graphene contents on the bending strength, fracture toughness, micro-hardness, phase compositions, and microstructure evolutions of SiC ceramics were investigated in detail. Enhanced fracture toughness of the SiC ceramics was achieved by proper addition of graphene.

α -SiC powders (Hengxin Silicon Carbide Micropowder Co. Ltd., as described in Table 1), graphene powders (Hefei Vigon Materials Technology Co., Ltd., as described in Table 2), B4C (Mudanjiang Jingangzuan Boron Carbide Co. Ltd., D50~1.5 µ m, purity > 97.0%), and liquid phenolic resin (PF, theoretical carbon content 40.0 wt%, acting as binder and C source, LaiwuRunda New Material Co., Ltd.) were used as raw materials. SiC, graphene, B4C, and PF with a certain mass ratio were ball-milled in a Nylon pot with SiC balls and ethanol for 24 h. After ball-milling, the mixtures were dried, crushed, sieved, and uniaxially dry pressed into cylinder samples with a diameter of 65 mm and a height of 6 mm under 30 MPa. Subsequently, the samples were isostatically pressed under 200 MPa for 300 s. The sintering was performed in a graphite resistance furnace in flowing Ar, holding for 1 h under 2130 ° C. During the sintering process, the pyrolytic C from PF reduced the SiO2 on the surface of the SiC powder to increase surface free energy, while the B from B4C dissolved into the SiC to modify the properties of grain boundaries by lowering the grain boundary energy. That is, the PF and B4C together promoted the densification of the SiC ceramic. The raw material compositions of each sample are listed in Table 3.

| Table 1. Physical characteristics of the raw α -SiC powders |

| Table 2. Physical characteristics of the raw graphene powders |

| Table 3. Raw material compositions of each sample |

The sintered samples were ground and cut with a diamond saw into bars. The bars were mirror polished using diamond slurries. The three-point bending strength measurement was carried out using an electromechanical universal testing machine (CMT 5105, Shenzhen Suns Technology Co., Ltd.) at a speed of 0.5 mm/min with a span of 20 mm at room temperature. The fracture toughness of the samples was measured by a three-point loading and single-edge notched beam technique with a notch of 0.1 mm width and 1.0 mm depth, a span of 20.0 mm and a speed of 0.05 mm/min. Seven bars of each sample were tested to obtain an average value, and all the bars for both bending strength and fracture toughness measurements were of 3 mm × 4 mm × 40 mm. Micro-hardness was determined by the Vickers indentation method (DHV-1000, Shanghai Caikon Optical Instrument Co., Ltd.) at a load of 4.90 N for a dwell time 15 s on the mirror-polished surface. Seven separate indentations were performed on each sample, and the mean of the measured values was reported here. Microstructural observation and composition analysis were carried out using a field emission high-resolution scanning electron microscope (SU-70, Hitachi) attached with an energy dispersive X-ray spectroscopy (EDX) detector (EX350, Horiba).

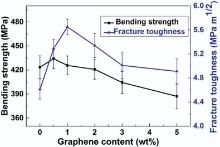

The effects of different graphene contents on the bending strength and fracture toughness of pressureless-sintered SiC ceramics are shown in Fig. 1. As the graphene content increases from 0 to 5.0 wt%, the bending strength of the SiC samples increases slightly at first, and then decreases quickly, achieving the highest bending strength of 434.14 MPa at the graphene content of 0.5 wt%. Similarly, it is also observed that the fracture toughness of SiC samples presents a sharp increase initially and then a decrease with increasing graphene content. The highest fracture toughness of 5.65 MPa⋅ m1/2 is obtained for the sample with 1.0 wt% graphene, which is about 22.6% higher than that of SiC sample without graphene. Moreover, the values for fluctuation ranges for both the bending strength and fracture toughness of the SiC samples become smaller when the graphene content is about 1.0 wt%. This indicates that adding proper amount of graphene into SiC ceramic matrixis conducive to reduce the fluctuation ranges of the bending strength and fracture toughness for the pressureless-sintered SiC ceramics, thus improving the reliability of the as-obtained SiC ceramics in service period.

| Fig. 1. Effects of different graphene contents on the bending strength and fracture toughness of the SiC samples. |

Generally, the bending strength and fracture toughness for most ceramics are in proportion with the relative density. Ceramics with a low relative density always have many pores in the matrix, and this implies loose microstructure and weak bonding strength of grain boundaries, thus resulting in low bending strength and fracture toughness. In this study, the bending strength of the SiC samples roughly decreases with the relative density, which monotonically decreases from 99.18% to 96.66% when the graphene content increases from 0 to 5.0 wt% in our previous study[24], and this is consistent with the illustration above. The tiny increase in the bending strength of the SiC samples with 0.5 wt% graphene is mainly attributed to the superior mechanical properties of the graphene. However, the fracture toughness of the SiC samples with graphene content less than 1.0 wt% exhibits a sharp increase with decreasing relative density. This is attributed to the graphene added into the SiC, which can influence the microstructure of the SiC ceramic and the propagation path of the fracture in the SiC ceramic.

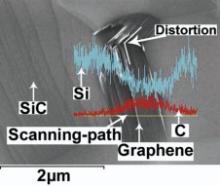

Fig. 2 shows the EDX line scanning of SiC sample with 1.0 wt% graphene. When the EDX scans across the rugged region, the signal of C element exhibits a sharp increase, while that of Si element exhibits an obvious decrease. This accords well with the total Si and C elements fractions on the EDX scanning line in Table 4, indicating that the rugged region is mainly composed of C element. Such large amount of C is unlikely to derive from pyrolysis of the PF. For one thing, the pyrolytic C should distribute evenly throughout the SiC samples; for another thing, the pyrolytic C should not be rugged. Therefore, the rugged fractured surface should correspond to graphene, and the relatively smooth fractured surface is SiC. The XRD analysis in our previous study[24] also proves the existence of the graphene and its well compatibility with SiC even at high temperature of 2130 ° C. Furthermore, it is observed (Fig. 2) that the interfaces between graphene and SiC are closely combined without obvious pores, and the graphene layers are distorted and deflected. The distortion and deflection of the graphene layers, which are probably caused by the squeeze action during the compression and sintering shrinkage process, just like laminae in Ti3SiC2 ceramics[25], can increase the fracture toughness by dissipating part of the fracture energy.

| Table 4. Total elements content on the EDX scanning line |

The microstructure of the fractured surfaces of SiC samples with different graphene contents is shown in Fig. 3. Although there are very few obvious pores (Fig. 2) on the interfaces between graphene and SiC, it is observed (Fig. 3) that the pores in the samples increase gradually as the graphene content increases from 0 to 5.0 wt%. This changing trend is just reverse with that of the relative density. Especially, some pores between graphene layers are observed in the SiC sample with 5.0 wt% graphene (Fig. 3(f)). This is because too much carbon (here refers to graphene) blocks the mass transport processes and makes it difficult to obtain SiC ceramics with complete densification by pressureless-sintered method[26]. Some tearing-open regions are observed on the fractured surfaces of all the SiC samples with different graphene contents, which are conducive to improve fracture toughness by dissipating more fractured energy by increasing the total length of the crack propagation path [27]. Therefore, the SiC samples with 1.0 wt% graphene, showing the most obvious tearing-open regions, exhibit the highest fracture toughness.

| Fig. 3. SEM images of fractured surfaces of SiC samples with different graphene contents: (a) 0 wt%, (b) 0.5 wt%, (c) 1.0 wt%, (d) 2.0 wt%, (e) 3.0 wt%, (f) 5.0 wt%. |

Fig. 4 shows the high magnification scanning electron microscopy (SEM) images of the fractured surfaces of SiC samples with different graphene contents. Although the fractured surfaces of all SiC samples with different graphene contents exhibit some tearing-openregions( Fig. 3 and Fig. 4), the smoothness of the fractured surfaces is much different. For the sample (Fig. 4(a)) with 0.5 wt% graphene, the fractured surface is comparably smooth and neat. However, when the graphene content is more than 2.0 wt%, the fractured surface (Fig. 4 (b) and (c)) turns to be considerably rugged. The rugged fractured surface is expected to improve fracture toughness of the SiC samples, because it can prolong the transmission path of fracture, thus dissipating more fracture energy. Furthermore, the relative sliding, or delamination like in the laminated Ti3SiC2 ceramics [28, 29], between graphene layers on the fractured surface is observed (Fig. 4(b)). This is because the graphene, just like the graphite, exhibits high mechanical properties within a layer but relatively weak combination between layers. The relative sliding, or delamination, between graphene layers can also dissipate part of the fracture energy, leading to an increase in the fracture toughness [28, 29].

| Fig. 4. High magnification SEM images of fractured surfaces of SiC samples with different graphene contents: (a) 0.5 wt%, (b) 2.0 wt%, (c) 5.0 wt%. |

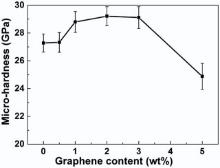

The effect of different graphene contents on the micro-hardness of pressureless-sintered SiC ceramics is shown in Fig. 5. It is found that the micro-hardness of the SiC samples increases slightly from 27.28 to 29.21 GPa at first with the graphene content increasing from 0 to 2.0 wt%, and then decreases quickly from 29.21 to 24.88 GPa as the graphene content increases from 2.0 to 5.0 wt%. The slight increase in micro-hardness of the SiC samples with the increasing graphene content can be explained by the observation that graphene can lead to microstructure refinement. Balog et al.[30] have proposed that microstructure refinement can increase the hardness by hindering the dislocation motion within silicon nitride matrix grains. This might happen to be the possible mechanism that adding graphene could improve the micro-hardness of the SiC samples. The low micro-hardness of the SiC samples with 5.0 wt% graphene is attributed to low density, for the low density SiC samples contain many pores, which can reduce the hardness remarkably[31].

Fig. 6 demonstrates the metallographic images of the polished surface with indentations of SiC samples with different graphene contents. The indentations of the SiC samples are legible and regular without obvious fracture at lower graphene content from 0 to 3.0 wt%; however, when the graphene content is up to a higher level (e.g. 5.0 wt%), the indentations are almost completely fractured without distinct corners. In addition, as the graphene content increases from 0 to 1.0 wt%, the cracks resulting from the indenting become longer and wider, and the faint crack branching is also observed. However, when the graphene content increases from 2.0 to 5.0 wt%, the crack propagation becomes inconspicuous. Especially, the crack is nearly invisible for SiC sample with 5.0 wt% graphene, because the indentation is almost completely fractured and the fractured indentation can dissipate most of the fracture energy, thus leading to little obvious crack propagation. Both the obvious crack propagation and faint crack branching in SiC sample can dissipate much fracture energy, and this might account for the SiC sample with 1.0 wt% graphene exhibiting the highest fracture toughness.

| Fig. 6. Metallographic images of polished surface with indentation of SiC samples with different graphene contents: (a) 0 wt%, (b) 0.5 wt%, (c) 1.0 wt%, (d) 2.0 wt%, (e) 3.0 wt%, (f) 5.0 wt%. |

On the whole, for solid-state pressureless-sintered SiC ceramics with graphene, the pores in the samples increase monotonically (Fig. 3 and Fig. 6) with the increasing graphene content, consequently resulting in a decreasing relative density of the SiC samples, because too much graphene makes it difficult to obtain complete-densification SiC ceramics by pressureless-sintered method. The low relative density makes it difficult for graphene to exert its superior mechanical properties as a reinforced component in the SiC ceramic matrix. Therefore, it is possible to achieve SiC ceramics with a higher fracture toughness, bending strength, and hardness, if the pores in the SiC samples with high graphene content can be eliminated during the sintering process by other sintering methods, such as by hot-pressing method or by spark plasma sintering method.

SiC ceramics with different graphene contents were fabricated by solid-state pressureless-sintered method. The effects of graphene on the fracture toughness, bending strength, micro-hardness, phase compositions, and microstructure evolutions of the SiC ceramics were investigated. The fracture toughness of the SiC samples increased remarkably with increasing graphene content. This was attributed to the superior mechanical properties of the graphene, and the toughening mechanisms of the distortion and deflection of the graphene layers, the tearing-open regions on the fractured surface, the relative sliding between graphene layers, the crack propagation, and the faint crack branching, which could all dissipate part of the fracture energy. However, when the graphene content was above 2 wt%, the fracture toughness of the SiC samples decreased significantly because of the low relative density. Thus, we propose that if the pores in SiC sample with high graphene content can be eliminated, such as by hot-pressing method or by spark plasma sintering method, its fracture toughness, bending strength, and hardness are expected to increase considerably.

The authors have declared that no competing interests exist.

| [1] |

|

| [2] |

|

| [3] |

|

| [4] |

|

| [5] |

|

| [6] |

|

| [7] |

|

| [8] |

|

| [9] |

|

| [10] |

|

| [11] |

|

| [12] |

|

| [13] |

|

| [14] |

|

| [15] |

|

| [16] |

|

| [17] |

|

| [18] |

|

| [19] |

|

| [20] |

|

| [21] |

|

| [22] |

|

| [23] |

|

| [24] |

|

| [25] |

|

| [26] |

|

| [27] |

|

| [28] |

|

| [29] |

|

| [30] |

|

| [31] |

|