Pathogen microorganisms exist in various environments such as dairy processing facilities. They are not easily eliminated, and significantly raise the risk of bacterial contamination. The inhibition ability of a novel type 304 Cu-bearing stainless steel (304CuSS) with nano-sized Cu-rich precipitates against Staphylococcus aureus (S. aureus) and Pseudomonas aeruginosa (P. aeruginosa) added whole milk was investigated in this study. The results showed that after 24 h contact, the inhibition rates of the 304CuSS against S. aureus and P. aeruginosa added whole milk reached 99.2% ± 0.3% and 99.3% ± 0.2%, respectively, in contrast with the 304SS. In the plain whole milk, the inhibition rate of the 304CuSS also reached 66.9% ± 2.0% compared with the 304SS. The results demonstrated that the 304CuSS killed majority of the planktonic bacteria, and inhibited sessile bacteria adherence to the steel surface in the whole milk with and without bacteria addition, significantly reducing the bacterial growth rate. These research outcomes explicitly show an application potential of this novel antibacterial stainless steel in the dairy related food industry.

Pathogen microorganisms are known for their detrimental effects on human health, especially children and elder people[1, 2, 3]. Milk is highly nutritious and provides an ideal environment for the growth of pathogenic and spoilage organisms, such as Staphylococcus aureus (S. aureus) and Pseudomonas aeruginosa (P. aeruginosa) [4]. The bacteria in the dairy environment can significantly increase the risk of food-borne disease and poisoning once the food is contaminated. The persistence of the microorganisms in food preparation utensils has been increasingly gaining public concerns, and studies of bacterial adhesion to the stainless steels used in food industries have been reported[5].

However, previous studies were more focused on the pathogens or biofilm formations on the stainless steel without consideration of characteristics of stainless steel, especially the surface physics and chemistry. This study is intending to examine the interaction between a novel Cu-bearing antibacterial stainless steel (304CuSS) and the bacteria that commonly exist in the dairy facilities. The 304CuSS has a microstructure with certain amount of nano-sized Cu-rich precipitates homogeneously distributed in the austenitic matrix after an aging treatment. Previous examinations of the 304CuSS have widely exhibited its antibacterial ability against various microorganisms, i.e., E. coli (ATCC25922), S. aureus (ATCC25923), Serratia marcescens (ATCC8100), Enterococcus faecalis (ATCC29212) and P. aeruginosa (ATCC9721) [6, 7, 8, 9]. The 304CuSS possesses long-lasting antibacterial ability because trace amount of copper ions (Cu2+) can be continuously released from its surface[8].

The pathogenic bacteria that exist in dairy processing facilities often include planktonic bacteria and biofilms. Once the biofilm forms, the resistance of the bacteria to the disinfectants or antibacterial products will be resilient. Bacterial biofilms can be very obstinate and can even cause serious engineering issues, such as mechanical blockage, and bio-related corrosion of the base materials. These biofilms can be often more resistant to disinfection than that of planktonic organisms[10]. Therefore, preventions of bacterial biofilm adhesion/formation on the substrate material during transportation, storage and processing of dairy products are a primary concern for the dairy industry.

Stainless steels, a class of popular materials for equipment and facilities available in almost all levels of the dairy processes, are believed to be one of the most susceptible substrate materials for bacterial adhesions because of their biocompatible nature[11]. It has long been recognized that copper (Cu) or copper alloys possess strong antibacterial properties that could reduce the bacterial infection. Especially, they can kill more microorganisms in the dry environment during short time than those in the moist one in laboratory conditions because of a large amount of copper ions accumulated on their surfaces[12]. However, so far, there is still no standard method to evaluate the antibacterial performance of such novel steel against the bacteria in the actual environments[13, 14, 15]. Thus, it is also crucial to understand the antibacterial performance of this material against microorganisms in the dairy industry. Therefore, the 304CuSS was investigated in this study to evaluate its specifically antibacterial properties in the whole milk by using plate counting (PC), contact angle measurement and epifluorescence microscopy showing the adhesion ability of live bacteria to the steel.

The type of 304 stainless steel (304SS) sheet for this study was purchased from Taiyuan Steel Co., China, and the 304CuSS was smelted in a vacuum induction melting furnace on the basic composition of 304SS with appropriate addition of Cu. All the samples were prepared in size of 10 mm × 10 mm × 1 mm for the antibacterial tests. The analyzed chemical compositions of both steels are listed in Table 1.

| Table 1. Chemical compositions of experimental stainless steels (wt%) |

The 304CuSS was heated at 1040 ° C for 30 min followed by quenching in water, and then aged at 700 ° C for 6 h to produce Cu-rich precipitates in 304CuSS for the antibacterial ability[6]. The samples were successively grounded by using 600 to 1000 grade SiC papers, followed by acetone rinsing and ultrasonic cleaning for 15 min in ethanol, and finally dried in air. The samples were sterilized under UV light for 30 min prior to use.

In order to be close to the actual environments, a whole milk (Pure milk, Deyatü r lnc., Germany) was chosen as a culture medium to investigate the antibacterial performance of the 304CuSS. The milk was pasteurized in the dairy production processes prior to the market. The nutrient compositions (per 100 mL) of the milk was listed as follows: energy 267 kJ, protein 3.3 g, fat 3.5 g, carbohydrate 4.8 g, sodium 50 mg, calcium 120 mg. The test temperature was set at 25° ± 1.0° .

S. aureus (ATCC25923) and P. aeruginosa (ATCC21328) were purchased from Guangdong Microbiology Culture Center, Guangzhou, China. The bacteria were incubated and cultured overnight in the shaker at constant temperature of 37 ° C before the test. The initial concentration of bacteria was adjusted to be (2-5) × 103 CFU/mL.

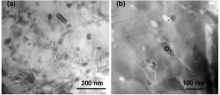

After aging treatment, slice samples of 0.4 mm in thickness were cut from the 304CuSS for Cu-rich precipitates observation on a high-resolution TEM (JEM-2010, JEOL, Japan) with point resolution of 0.19 nm. The samples were mechanically ground to the thickness of 30 µ m, and then thinned to foils by standard twin jet polishing and ion milling prior to TEM observation. This was followed by fine structural examination and energy dispersive X-ray spectrum (EDX) analysis with high-angle annular dark field (HAADF). The electron energy loss spectrum (EELS) nano-probe analysis was also conducted on a FEG-Tecnai30 electron microscope.

In order to examine the antibacterial abilities of steel samples against S. aureus and P. aeruginosa in the whole milk, the standard direct plate counting methodology reported in the literatures [8, 9] was used to examine the number of planktonic bacteria existed. A solution with 0.9% NaCl (physiological saline) (w/v) was adopted as a diluent, and was sterilized by an autoclave for 20 min before test. Samples of both 304CuSS and 304SS were placed into a sterilized 24-well plate, and then 1 mL of the whole milk with S. aureus and P. aeruginosa, respectively, and the milk without bacteria (as control) were separately poured into the plates with 304CuSS and 304SS samples, which were co-cultured at 25 ± 1.0° C in an incubator for 3 h, 6 h, 12 h and 24 h, successively. Diluted by physiological saline, serial concentrations of bacteria were placed onto the plates [16]. Colonies were counted and the results were expressed in log (CFU/mL). Five groups for a same sample were used for the testing results, and standard deviation (SD) was also calculated. Inhibition rate was calculated by following equation:

A2=(A0-A1)× 100%/A0 (1)

where A2 is the inhibition rate, A0 is the planktonic bacterial count after exposure to the 304SS, A1 is the planktonic bacterial count after exposure to the 304CuSS.

Contact angles were obtained using the sessile drop method by a contact angle analyzer (OCA-20, Dataphysics, Germany). After the samples were exposed to the whole milk with or without bacteria for 24 h, the surfaces of the samples were washed three times and the planktonic bacteria adhered to the samples were removed by using 10 mL of sterile distilled water. The mean contact angles of four random points on the sample surface were regarded as the contact angle of each tested sample at 25 ° C[17].

The sessile multi-species microorganisms on the steel surfaces were examined after contact with steels for 24 h. The samples were taken out of the milk and fixed in 4% (v/v) glutaraldehyde for 4 h. They were then dehydrated by ethanol successively for 30 min with concentrations of 25%, 50%, 75% and 100% (v/v). The steel surfaces were finally sputter-coated with gold for surface observation on a field emission scanning electron microscope (SEM) (SUPRA 55, ZEISS, Germany) according to the standard SEM operation procedure[18]. The chemical compositions of samples were analyzed by energy-dispersive spectrometry (EDS).

Epifluorescence microscopy (Carl Zeiss Inc., Oberkochen, Germany) was used to evaluate the growth and distribution of bacteria on different sample surfaces for 24 h. After removing planktonic bacteria from the samples, the sessile bacteria or biofilms on sample surfaces were stained with 4', 6-diamidino-2-phenylindole (DAPI) (0.5 µ g/mL) for 10 min prior to microscopic examination and then rinsed with PBS for three times[19].

All the data in this study represented the mean ± SD of experimental replicates and every experiment was repeated three times.

Previous studies demonstrated that a synergy between the ε -Cu phase and the steel matrix could offer the 304SS strong antibacterial performance compared to that of the 304SS[7]. The TEM observation shown in Fig. 1 also revealed that the morphologies of precipitations of the Cu nanoparticles and clusters were in a good conjugation with the stainless steel matrix within the 304CuSS aged at 973 K for 6 h. Accordingly, these nano-scaled particles shown in Fig. 1 should be prevailingly the Cu-rich precipitates[20]. These rod-like shaped Cu-rich precipitates in the 304CuSS showed their average size in length to be around 80 nm (Fig. 1(a)).

In order to confirm the Cu-rich precipitation prevalence in the steel matrix, the Cu-rich precipitates were further proved in the HAADF image, as shown in Fig. 1(b). Meanwhile, the corresponding composition analyses made by SEM-EDX confirmed the Cu-rich precipitates as listed in Table 2. These results illustrated that these particles within the matrix possessed higher concentration of Cu (19.6 wt%) in comparison with the average Cu content (3.8 wt%) in the matrix. Thus, these Cu-rich precipitates distributed in microstructure were identified as ε -Cu phase.

| Table 2. EDX analyses of the precipitate and matrix in the 304CuSS (wt%) |

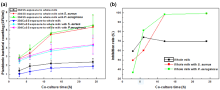

It was demonstrated that the number of planktonic bacteria was growing steadily in the whole milk after contact with the experimental steels. However with extension of the contact time to the 304SS, the bacteria in the whole milk were significantly increased.

The number of planktonic bacteria in the whole milk after contact to the 304SS increased gradually with the contact time for 3, 6, 12 and 24 h, respectively. Compared with the 304CuSS, as shown in Fig. 2(a), the bacterial increment on the 304SS was over 9 times after 24 h contact, as observed from the bacterial counts on plates. A modest increase of bacteria was observed in the whole milk after contact with 304CuSS for 24 h. After 24 h contact with the milk, the inhibition rate of the 304CuSS against planktonic bacteria was from 59.2% ± 1.3% (3 h) to 66.9% ± 2.0% (24 h) in comparison with the 304SS (Fig. 2(b)), indicating that the 304CuSS more effectively delayed the bacteria growth than the 304SS.

Furthermore, when the whole milk containing S. aureus (4.0 × 103 CFU/mL) contacted with steel samples, the number of planktonic bacteria increased much faster than those in the plain whole milk, as shown in Fig. 2(a). Bacterial colonies increased from 2.51 ± 0.3 log (CFU/mL) to 4.27 ± 0.9 log (CFU/mL) after contact with the 304CuSS from 3 h to 24 h. However, there were more bacterial colonies on the 304SS from 2.81 ± 0.3 log (CFU/mL) to 6.36 ± 1.3 log (CFU/mL) after contact with bacteria for the same periods. Therefore, the bacteria were easily survived and propagated on the 304SS. The 304CuSS killed 99.2% ± 0.3% of bacteria after 24 h contact to the whole milk with bacteria addition in contrast to the 304SS, as shown in Fig. 2(b).

When the 304SS was immersed in the whole milk with P. aeruginosa addition (5.0 × 103 CFU/mL) for different time durations, the number of planktonic bacteria almost increased 4.3 × 103 times more than those immersed with the 304CuSS (1.0 × 103 times) from 3 h to 24 h, as shown in Fig. 2(a). The increment of planktonic bacteria count for contact with the 304SS was 43 times higher than the 304CuSS, reaching to 6.78 ± 1.2 log (CFU/mL) in 24 h. On the contrary, only 4.56 ± 1.1 log (CFU/mL) of bacteria appeared in the same whole milk contact to the 304CuSS, with inhibition rate of 99.3% ± 0.2% against planktonic bacteria compared with the 304SS, as shown in Fig. 2(b). Hence, the 304CuSS did show an obvious antibacterial performance against planktonic bacteria in the whole milk with or without bacteria addition in comparison to the 304SS, indicating that the 304CuSS could significantly lower the risk of bacterial contamination to milk.

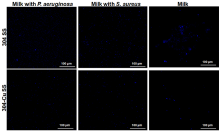

Morphologies of sessile bacteria on surfaces of steel samples in the whole milk are shown in Fig. 3, in which the steel samples were immersed in the whole milk for 24 h with and without bacteria addition. The results showed that after contact with steel samples, not only single sessile bacterium but also clustered bacteria in the form of biofilms appeared on the surface of the 304SS, while only a few scattered bacteria were observed on the 304CuSS surface, indicating that the sessile bacteria were much easier to be adhesive to the 304SS than the 304CuSS. In addition, it can be found from Fig. 3 that the island-like thick biofilms were found on the 304SS steel surface after exposure to the whole milk containing bacteria, while only long rod-like and thin clusters appeared on the same steel contact to the milk without bacteria. The bacterial morphology observations demonstrated that once the whole milk was contaminated with bacteria, the bacterial biofilms on the 304SS surface could develop and become difficult to be removed.

The chemical compositions of the 304CuSS surface after contact with different mediums for 24 h are listed in Table 3. A certain amount of Cu concentration on the steel surface demonstrated that the contact of the 304CuSS to different mediums would guarantee enough release of Cu2+ into the surrounding environments.

| Table 3. Chemical compositions of the 304CuSS surface after contact to whole milk with and without bacteria addition for 24 h (squares in Fig. 3) (wt%) |

Live sessile bacteria on the steel surfaces were also examined by DAPI staining and observed under epifluorescence microscopy, as shown in Fig. 4. A series of images of bacterial adhesions on the steel surfaces reflected the different antibacterial properties of the 304CuSS and the 304SS after 24 h contacts with the whole milk with and without bacteria addition. The images showed the variations of sessile bacteria growth on the steel surfaces contact to the whole milk by the sessile bacteria spots in blue, indicating a dynamic process on bacteria formation and succession on two different steel samples. As shown in Fig. 4, a large amount of live sessile creatures were accumulated and clustered on the 304SS surface, while by contrary, only a few scattered bacteria were observed on the 304CuSS surface, which is well in accordance with the results shown in Fig. 3.

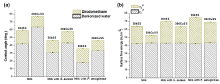

The formation of biofilm is a process containing two successive steps, beginning with the initial attachment to a contact surface followed by the accumulation of multi-layer cell clusters— intercellular adhesion[21]. Once sessile bacteria are fixed/adsorbed on the substrate, they will evolve easily into biofilms by gathering together. In this study, after removing the planktonic bacteria on steel surfaces, the contact angle was measured to characterize the physiological performance of the substrate materials after contacted with milk for 24 h, as shown in Fig. 5. Surface free energy (SFE) of the substrate was used to describe the surface affinity ability to the biofilms and was calculated by using the following standard equation[22]:

where γ L is the experimentally determined surface tension of the liquid; θ is the contact angle;

| Fig. 5. Surface analyses of stainless steel samples after contact to the whole milk with different bacteria for 24 h; (a) contact angle; (b) surface free energy (SFE). |

After the diiodomethane was dropped onto surfaces of both steels, it was found that the contact angles of their surfaces were not significantly changed. While dropping the deionized water onto the steels, the contact angle for the 304CuSS was much higher than that of the 304SS. It has been referred that the effect of deionized water on the substrate surface was more prevalent compared to diiodomethane. The relevant polar component showed an obvious function for the surface free energy (SFE) calculation, as shown in Fig. 5(b). After contact to the whole milk for 24 h, there was a large difference on SFE between both steels. The mean value of SFE (63.9 ± 0.08 mJ m-2) for the 304SS was obviously higher than that for the 304CuSS (52.6 ± 0.12 mJ m-2).

Likewise, the mean values of SFE for the 304SS after contact to milk containing S. aureus (69.8 ± 0.29 mJ m-2) and P. aeruginosa (74.7 ± 0.15 mJ m-2) were also higher than those for the 304CuSS (63.5 ± 0.42 mJ m-2 and 68.8 ± 0.82 mJ m-2, respectively).

In addition, the values of SFE for the steels contact to the whole milk with P. aeruginosa and S. aureus were much higher than those with contact to the plain whole milk. This indicates that the stronger sessile bacteria adhesion, affinity on the steel surface was produced by the whole milk with bacteria addition.

The excellent antibacterial ability of the 304CuSS against microorganisms could inhibit the sessile bacteria adhesion and succession on its surface, which is in agreement with the epifluorescence observation shown in Fig. 4. These results demonstrate that the risk of bacterial contamination to milk contact with the 304SS is obviously higher than that with the 304CuSS, regardless whether or not the milk with or without bacteria addition. Especially for prevention of long duration of bacterial contaminations, the 304CuSS provided much better antibacterial results and anti-biofilm formation capabilities than those of the 304SS.

As shown in Fig. 4, fresh milk contains relatively fewer bacteria, but contamination during handling can rapidly multiply the bacterial quantities. Multi-species microorganisms, such as Escherichia coli, Pseudomonas, Staphylococci and Bacillus cereus are normally present in milk [23], which can cause the deterioration of milk, and even possibly lead to cross-contaminations to human, animals as well as environments.

Bacterial adhesion is a physicochemical phenomenon controlled by features of the microorganism, substrate properties and liquid medium[24]. Once the biofilms are adsorbed (attached/adhered) on the surface of a material, they are hard to be removed, by which a series of problems can be easily brought about to cause a serious food contamination and safety issues. Especially, the extracellular polymeric substances (EPS) can gradually grow with a metabolism proceeding, as being generally considered vital in cementing bacterial cells together to form the biofilm structure[25]. In this study, the number of sessile bacteria grown on the 304CuSS was far fewer than that on the 304SS, as shown in Fig. 4, indicating a considerable less EPSs growth on the 304CuSS surface.

During the biofilm formation, some trace organisms first adhered to the material surface to form a conditioning layer, directly leading to a formation of SFE. The testing results of SFE on the steel samples revealed that the sessile bacteria were of much affinity to the surface of the 304SS than that of the 304CuSS. This suggests a better adhesive binding between bacteria and the 304SS, wherein the EPS would support the biofilm formation on its surface.

Biofilm formations observed in this work were also reported with the similar bacterial-substrate contact angle and SFE values[26]. These concluded the changes of surface functionalities between fresh substrate stainless steels and the same surface after exposed to biological fluids, similar to their surface treatment. In the case of stainless steels, if the surface free energy becomes lower, the bacterial adhesion becomes weaker to bind to the steel surface[27]. The present results indicate that the 304CuSS possessed lower surface energy, leading to the inhibition of the biofilm formation and bacterial propagation, which significantly restricted the further EPS adhesion toward the steel surface. It is also worthy to mention that the bacterial contamination of milk can result in a fast growth of bacteria in the milk medium, leading to the breach against the industrial quality control standard. A hypothesized explanation can be that by increasing the secretion of substances from the bacterial metabolites, the composition and physiological characteristics of the general dairy products will be destructed, thus causing deterioration of physical and chemical stabilities of the whole milk[28, 29].

These antibacterial tests on the 304CuSS against planktonic bacteria in the milk were carried out for a 24 h period, and a strong antibacterial performance was demonstrated in comparison to that of the 304SS. It was reported that the antibacterial functionality was because of a continuous release of trace amount of Cu2+ ions from the 304CuSS surface, which induced the collapse of the LPS patches of the bacterial cell surface, consequently altered the permeability and functionality of the outer cell membrane, and finally caused the death of planktonic bacteria[6].

The antibacterial functionality of the 304CuSS was proved by the relevant tests in the whole fresh milk with and without bacteria addition, respectively. The work was more concentrated on the evaluations of the performances of the 304CuSS against S. aureus and P. aeruginosa in the fresh whole milk. Through analyzing the microstructure and antibacterial performance of the 304CuSS, some conclusions can be drawn as follows:

(1)The Cu-rich nanoparticles precipitated in the 304CuSS were identified as the key factor in killing bacteria and inhibiting biofilm formation.

(2)Most of the planktonic bacteria were killed by the strong antibacterial ability of the 304CuSS through continuous release of Cu2+ ions, which also effectively inhibited the sessile bacteria adhesion and biofilm formation on the Cu-steel surface.

(3)The surface free energy data support that the bacteria were more readily to adhere to the surface of the 304SS compared to that of the 304CuSS.

(4)The 304CuSS could naturally delay and reduce the self-deterioration of the dairy products, and more importantly it could kill the bacteria from environments with bacterial contamination and inhibit their biofilm formation as well.

This work was financially supported by the National Natural Science Foundation of China (Nos. 51101154 and 51371168), the National Basic Research Program of China (No. 2012CB619101), the UK Royal Academy of Engineering (RAEng.1213RECI052), and the Shenyang National Laboratory for Materials Science.

The authors have declared that no competing interests exist.

| [1] |

|

| [2] |

|

| [3] |

|

| [4] |

|

| [5] |

|

| [6] |

|

| [7] |

|

| [8] |

|

| [9] |

|

| [10] |

|

| [11] |

|

| [12] |

|

| [13] |

|

| [14] |

|

| [15] |

|

| [16] |

|

| [17] |

|

| [18] |

|

| [19] |

|

| [20] |

|

| [21] |

|

| [22] |

|

| [23] |

|

| [24] |

|

| [25] |

|

| [26] |

|

| [27] |

|

| [28] |

|

| [29] |

|