Qianlong Xuan paper, lost two hundred years ago, was reproduced by engineers in Red-Star Xuan Paper Limited Liability Company of China. Its remarkable performance and profound historical value are highly regarded by artists and the paper commands very high price in the commercial market. Ink penetrates and spreads optimally in the paper and the words exhibit clear edges with small fluctuations because of the desirable wettability and wicking. These characteristics make it stand out from three Xuan paper samples. The good wettability, verified by contact angle measurements, is an essential prerequisite to strong wicking. Attenuated total reflectance Fourier-transform infrared spectroscopy is performed to determine the chemical structure of Qianlong Xuan paper and the relatively large hydrogen bonding ratio contributes to the hydrophilicity. The microstructure investigated by scanning electron microscopy and atomic force microscopy reveals wide fibers and a uniform fiber arrangement with good connectivity, dense network, as well as rough fiber surface. These unique properties endow Qianlong Xuan paper with strong wicking to improve the ink expression.

Xuan paper, also called rice paper in Japan, is used widely in traditional calligraphy and painting and is a prominent type of Chinese handmade paper. It has been widely popular with calligraphers and painters since its inception in the Tang Dynasty (618-907 AD). Progressive calligraphers are always on the quest to show their expression, which cannot be achieved without Xuan paper and in fact, good Xuan paper makes the arts more impressive.

Xuan paper manufactures are scattered all over the country. Red-star paper mill, located in Jing County, Anhui Province, China, is one of the best and Jing County is believed to be the home of the Xuan paper, where the “ traditional handicrafts of making Xuan paper” is listed as a UNESCO World Intangible Cultural Heritage[1].

Xuan paper is made of pulped fibers of blue sandalwood bark and rice straws. According to different raw material ratios, Xuan paper is classified into three types, Tejingpi, Jingpi, and Miaoliao, in which the ratios of wingceltis bark are more than 80%, no less than 60%, and about 40%, respectively. In general, the ink expression is better for a larger ratio of the bark fibers. The production of Xuan paper uses natural materials and reagents and manual tools but the process is complex and varies with different manufacturers. Normally, the production of traditional paper from raw materials requires 18 procedures and more than one hundred operations taking one to two years. Pulping is an essential process utilizing the stream in Jing County. Japan has used the same craft to produce Xuan paper but the properties are not as good as those produced in the Jing County. It is believed that the water in the stream affects the quality of the paper.

Xuan paper underwent large development in the Qing Dynasty peaking in the period of Qianlong after its advent[2]. Emperor Qianlong, skilled in writing, was deeply in love with Xuan paper. The Qianlong Xuan paper that belongs to Tejingpi is the ultimate writing and painting paper. In order to attract more attention to Xuan paper, Xing Chunrong, the chief engineer of the mill, reproduced the Qianlong Xuan paper that was lost two hundred years ago by collecting the related literature. The Qianlong Xuan paper, made by the best engineer in one of the best Xuan paper companies, has immense historical significance, rarity and unmatched performance and owing to the limited supply, it commands the highest price. The outstanding wetting properties of Qianlong Xuan paper are determined by the chemical constituents and physical structure, which are closely related to the raw materials and the manufacturing process and it is important to understand the scientific reasons for the outstanding performance.

In recent years, there has been widespread investigation in ink dispersion on Xuan paper in the computer graphics community. However, ink dispersion is a complex phenomenon that involves the interplay between paper, water and ink constituents, thus making accurate physical simulation difficult. Moxi[3] simulated ink dispersion in absorbent paper by adopting the Lattice Boltzmann Equation (LBE) method, but they neglected the effects of the paper structure on the actual process. Moreover, in many statistical physics experiments on liquid transport in porous media, paper is chosen for obvious and simple practical reasons. However, scientific research in wetting of traditionally handmade Xuan paper has been scarce, except Liu and Hu's report on the wetting property of Chinese ink on Xuan paper[4] in 1984 and Wu's study on the relationship between the production technique and performance of ink embellishment on Chinese Xuan paper[5]. However, both of them did not pay enough attention to the physical mechanism. Because of the lack of good understanding and considering the lofty status of Qianlong Xuan paper in Chinese arts and civilization, we want to unravel why Qianlong Xuan paper is so remarkable from the scientific perspective.

Two other kinds of high-quality Xuan papers, Jingpi and Bamboo papers, are chosen for comparison. The Qianlong Xuan paper and Jingpi were provided by Red-star paper mill in Jing County, and Bamboo paper was purchased from a local Xuan paper agent. The paper was cut into 6 cm × 3 cm, 1.5 cm × 1.5 cm and 6 cm × 6 cm pieces for contact angle measurements, scanning electron microscopy, and attenuated total reflectance Fourier-transform infrared (ATR-FTIR) spectroscopy, respectively. The specimens were placed in an oven at 60 ° C for 6 h to ensure complete water evaporation. The tested pieces weighing 0.2 g were put in 60 mL of deionized water under magnetic stirring at a low speed for 8 h to separate the fibers while not damaging them. Afterwards, the suspension containing the fibers was diluted with adding 200 mL of deionized water and the diluted suspension was dripped onto slides and silicon chips for fiber width and atomic force microscopy (AFM) measurements separately.

Calligraphers wrote on the three types of paper under the same conditions, for instance, same brush, same ink density, same speed and style. In order to gain further insights into the effects of ink dispersion under the controlled conditions, the ink with the same volume of 50 µ L is dropped onto the three types of papers from the same height of 1 mm.

The contact angle measurements were performed on the OCA200 (Dataphysics, Germany), FTIR spectroscopy was conducted on a Nicolet Nexus 870 spectrometer, scanning electron microscopy was carried out on the Hitachi S4800 scanning electron microscopy (SEM), and the roughness of the fiber surface was assessed by AFM (AFM, NanoScope IV NS4-1).

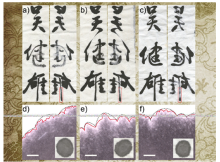

In Chinese calligraphy, artists utilize flexible brushes to create expressive strokes.Fig.1(a-c) shows three Chinese characters, Wu Chien-Shiung, a distinguished experimental physicist as well as an honorable graduate of Nanjing University (originally Central University). No ink is added until the first two characters are completed. It should be noted that the spreading of ink can be fully shown when the ink in the brush is rich. The first and third characters show better wetting with the characters written as soon as the ink is added on Qianlong Xuan paper. Moreover, the second character looks driest indicating that a great deal of ink has been consumed during the writing of the first character, meaning that the pressure between the outer edge of the ink front and beneath the brush tip is larger than the capillary suction pressure formed by voids between brush hairs. Considering the competition between the two kinds of pressure, it is certain that capillary effects affect the ink dispersion more significantly on Qianlong Xuan paper. The back of the artwork is also demonstrated on the right, showing that Qianlong Xuan paper has better performance of transverse wicking, which makes the ink flow in the paper to vividly pick up the special charm of ink dispersion. In order to gain further insights into the effects of ink dispersion under the controlled conditions, the ink with the same volume of 50 µ L is dropped onto the three types of papers from the same height of 1 mm. For the low-density ink, the Weber number is given by

We=2ρ rgh/γ , (1)

where ρ is the density, r is the radius, g is the gravitational constant, h is the height of free fall and γ is the surface tension of the drop. Taking typical values of ρ = 1000 kg/m3, r = 10-3 m, g = 10 m/s2, h = 10-3 m, and γ = 3 × 10-2 N/m, We is on the order of 1, much smaller than 50, and no splashing occurs [6].

The scanned images of the ink dispersion are exhibited in Fig.1(d-f) as insets and the boundary on Qianlong Xuan paper looks smoother. The spreading area is 24.5, 22.7, and 19.6 cm2 from left to right confirming best spreading on Qianlong Xuan paper. The enlarged views of the edges monitored by optical microscopy also demonstrate high contrast because except Qianlong Xuan paper, the edge cannot be seen clearly on the two other samples at low contrast. Meanwhile, it is obvious that the edge has small fluctuations, which display delicate tones better. Above all, the better wettability, transverse wicking, and longitudinal wicking make Qianlong Xuan paper better than the other papers.

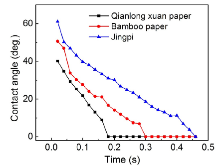

Wetting is a process in which a fiber-air interface is displaced with a fiber-liquid interface. Fiber wettability is a prerequisite to the occurrence of absorption and penetration. Wetting of paper, a fibrous assembly, is a complex process. The contact angle is useful in characterizing wetting. However, it is difficult to measure contact angles on heterogeneous and porous paper, since water will penetrate the underlying substrate and it will take some time for the drop to stabilize geometrically. Hence, the drop volume is chosen to be 4 µ L and the measurement takes 0.02 s after impact, which is the best compromise between geometric instability and onset of absorption. Considering the influence of various factors such as the surface roughness, chemical heterogeneity, and so on, the contact angles were measured repeatedly from two hundred different positions on each paper. The results are presented in Fig.2. The average values are as follows: 36.8° on Qianlong Xuan paper, 50.1° on Bamboo paper and 60.6° on Jingpi. The wettability of Qianlong Xuan paper is the best thus bonding well for absorption and spreading.

The wettability, which plays an important role in the paper, depends on both the chemical composition and geometric microstructure of the surface[7] and so the chemical composition is studied.

Plant fibers are composed of cellulose, hemicelluloses, lignin, pectin and wax substance, among which cellulose is recognized as the major framework component of the fiber structure. Cellulose, a linear1, 4-β -glucan polymer, contains three hydroxyl groups and consists of both amorphous and crystalline domains in varying proportions. In the crystalline regions, there are two hydroxyl groups that form hydrogen bonds within the cellulose macromolecules while the rest interacts with other cellulose molecules through hydrogen bonding[8]. It reduces the accessibility of hydroxyls to the reagent. Most of the reactants penetrate only the amorphous regions on the surface of the crystallites with a low level of order. Hence, the crystallinity of cellulose plays an important role in the water absorption characteristics.

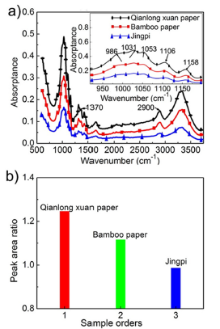

ATR-FTIR spectroscopy is one of the most useful methods to determine the surface composition without complex sample preparation and is used to study the hydroxyl groups and surface chemical bonding. As shown in Fig.3(a), in the fingerprint region, the characteristic bands at around 1040 cm-1 are assigned to the cellulose[9] and the broad band of OH-stretching vibration at 3000-3650 cm-1 is observed from all the spectra[10], indicating that cellulose is the main composition in the three types of paper. The enlarged vibration bands in the fingerprint region are presented in the inset of Fig.3(a). Except the main band of the cellulose at 1050 cm-1, the bands at 986, 1031, 1106, and 1158 cm-1can be assigned to C-O vibration at C(6), C-O stretching, ring asymmetric valence and C-O-C asymmetric vibration from β -glycosidic link in cellulose II[11, 12], respectively. Moreover, the band at 3341 cm-1 corresponds to O(3)H…O(5) intra-molecular hydrogen bond[13]. Because there is no much difference in the characteristic bands of cellulose, the bands in the range of 900-1200 cm-1 are chosen for the hydroxyl content determination. As shown in Fig.3(b), the ratios of the integrated intensity of OH-stretching vibration band at 3000-3650 cm-1 to the characteristic vibration band at 900-1200 cm-1 are 1.25, 1.12 and 0.96, respectively, for Qianlong, Bamboo and Jingpi Xuan paper, demonstrating that the hydrophilicity of Qianlong Xuan paper is strongest. Furthermore, the “ total crystalline index” (TCI), the ratio of the two bands between 1372 cm-1 (C-H bending) and 2900 cm-1 (C-H and CH2 stretching) is used to measure the crystallinity[14], which is 1.04, 1.06 and 1.14, respectively, for Qianlong, Bamboo and Jingpi Xuan paper, and hence, water gets access to the hydroxyls comparatively easily on Qianlong Xuan paper. Water molecules interacts with hydrophilic groups by hydrogen bonds to improve the surface hydrophilicity and water will enter and fill the grooves of the fiber network due to the capillary effect that results in the enhanced hydrophilicity.

Meanwhile, the pectin and wax in the plant fibers are responsible for the non-wetting behavior of water and these substances are removed from the process of alkaline cooking used in the manual manufacturing. For Qianlong Xuan paper made by the sophisticated methods, the residues may be few. As aforementioned, the stream in Jing County possibly affects the performance of the paper. There may be a linkage between the minerals in the water and the groups on the fiber surface resulting in the increased surface free energy of the fibers and decreased contact angle.

Wettability is the initial process, followed by wicking through the capillaries. When the liquid wets the fibers, it reaches the spaces between the fibers and the capillary flow is triggered. In oriental brush painting, when the brush used with a round bristle tip contacts the absorbent paper, some amounts of ink are transferred to the paper. The circumstance is similar to a drop deposited on paper and so it is necessary to understand how a drop interacts with paper.

A drop with a small contact angle accelerates absorption[15]. A poorly wetting liquid cannot easily penetrate the complex internal geometry of a porous system. It is well known that the drop exhibits a dynamic contact angle on porous paper. In order to understand the process clearly, the contact angles as a function of time on the three paper are shown inFig.4. The measurements are performed on ten replicates for each type of paper. The contact angles decrease most rapidly on Qianlong Xuan paper with the initial contact angle being the smallest. It favors the absorption of the liquid with the largest contact area. In turn, a slow decrease in the contact angles results from slow absorption by the bulk paper[16].

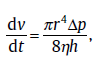

By modeling voids or “ pores” formed between fibers as a series of circular non-connected, parallel capillaries, the rate at which a liquid moves through the capillary tubes is related to the driving force by Poiseuille's law,

(2)

(2)

where r is the equivalent radius of the capillaries, η is the liquid viscosity, h is the distance within the tubes, and Δ p is the effective pressure gradient.

When a liquid front comes in contact with the entrance of a tube, a concave meniscus is produced. The typical Laplace pressure exerted by the formation of a meniscus at the interface is proportional to γ /r with γ being the surface tension of the liquid. The order of r is 10-5 m and so the pressure has the order of 103 Pa. The hydrostatic pressure between the top and bottom of the paper is in proportion to the thickness of paper. The order of the thickness is 10-4 m and therefore, the pressure is on the order of 1 Pa. The former is much more than the latter, so gravity can be neglected.

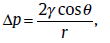

The driving force generated by the concave meniscus is described by:

(3)

(3)

where θ is the contact angle.

Combining Eqs. (2) and (3) leads to Eq. (4) (classical Washburn-Lucas equation[17]) as shown below:

(4)

(4)

According to Eq. (4), it can be concluded that a small contact angle and a large effective radius are beneficial to transverse wicking.

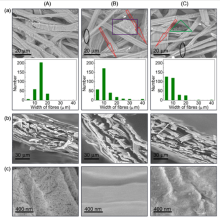

Compared to Jingpi, which has more short rice fibers as fillers marked as a triangle inFig.5(a), Qianlong Xuan paper contains more long bark fibers, which constitutes the backbone of the paper[4]. Short fibers can more efficiently pack in a dense network thereby reducing the permeability[18]. Additionally, there are chemicals as fillers marked as a rectangle on Bamboo paper in Fig.5(a). To a certain extent, there are more voids or pores in Qianlong Xuan paper. Therefore, there is no doubt that the effective radius of Qianlong Xuan paper is largest. Moreover, the permeability varies exponentially with the porosity over a long range of porosity[19]. This explains the distinct transverse wicking, too.

Xuan paper is thin, textured, and absorbent and supports all the nuance of nature's color as expressed by the shade of black, delicate brush strokes, and variations in the ink dispersion. Longitudinal wicking plays a crucial role in the successful expression.

The liquid ink is a diluted mixture consisting of water, soot, and glue[20]. Soot is composed of spherical primary carbon particles about 10 to 150 nm in size[21]. Because of the water pressure and capillary force, water flows slowly carrying pigments with it through the fibers while pigment diffusion itself can be neglected[3]. Thus, it is essential to fathom water flow, especially that associated with in-plane wicking.

Fibers morph into flat and flexible ribbons during sheet formation. As shown in Fig.5(a), the fibers are distributed relatively evenly in Qianlong Xuan paper, while the fibers overlap densely somewhere but the overlapping areas are far from each other as marked ellipses and arrows in Bamboo and Jingpi papers. The homogeneous fiber distribution may be related to natural paper additives such as kiwi fruit juice, which, as a dispersing agent, separates the fibers in the pulp suspension where flocculation of fibers takes place readily due to the various colloidal, electrostatic and mechanical attractive forces. When the gap formed between the fibers becomes wider, the meniscus radius increases, making the liquid progression more difficult. Thus, the ink flows correspondingly freely resulting in a large spreading area and a clear edge in Qianlong Xuan paper.

A smooth edge is related to the close global interconnectivity as well as good wettability. The greater connectivity of the interfaces in 3D leads to smooth advancing fronts below a critical contact angle. In addition, for a large contact angle, only parts of the pores are filled thereby resulting in a fractal-like wetting front[22]. Meanwhile, as the invading fluid becomes more wetting, cooperative invasion mechanisms may lead to a transition from fractal to compact growth, leading to smaller roughness of the interface[23]. For Qianlong Xuan paper, the good wettability has been verified. Hence, it should also have the best interconnection.

Concerning the interconnectivity, Hasuike et al. have demonstrated that a vast interconnected network is formed by the massive density of fiber overlapping[24]. The extent of fibers overlapping is assessed by SEM. The average statistical results of fibers overlapping per millimeter are 77, 52 and 40, respectively, for Qianlong, Bamboo and Jingpi Xuan paper. Most fiber overlapping in Qianlong Xuan paper matches expectation. Larger overlapping areas are related to more wider fibers. Thus, two hundred fibers are measured for each paper and the bar graph is exhibited in Fig.5(a). For Qianlong Xuan paper, the wide fibers are dominant. Furthermore, the distribution of the fibers is relatively localized, thus enabling the fibers to interweave to form an even surface, too. Moreover, as shown in Fig.5(b), the fiber web is much denser in Qianlong Xuan paper. The densities are 463, 356, and 429 kg/m3 for Qianlong, Bamboo, and Jingpi Xuan paper, respectively. When the liquid meniscus moves in the wedge-shaped channels with a small depth formed between overlapping fibers, the advancing front will be smoother due to the crossover length from nonlocal to local dynamic scale with the separation d as d1/2 for the spontaneous imbibiting fronts[25]. The cross-section of Bamboo paper is sparse corresponding to an irregular edge.

There are many grooves along the central axis of wingceltis bark fibers on the original smooth surface after natural drying[4]. According to the images of fibers at high magnification in Fig.5(c), the surface of the bark fibers shows grooves while the Bamboo fiber surface is relatively smooth. These grooves, as open capillaries, form potential flow paths with increasing surface roughness. In terms of micro-fluid dynamics, when a liquid flows in open V-shaped capillary grooves, the spreading length, z, of the liquid follows the following relationship:

z2=K(α , θ )[γ h0/η ]t, (5)

where K(α , θ ) is a geometric term containing the groove angle α and contact angle θ independent of the groove height, γ is the liquid surface tension, ho is the groove height, and η is the liquid viscosity, implying that a deeper groove helps the flow [26].

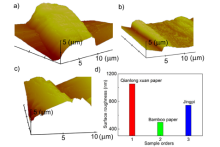

AFM is a useful supplement to SEM in characterizing surfaces. The AFM images of the fibers in the paper samples are displayed in Fig.6(a-c). The surface roughness of the wingceltis bark fiber looks the largest while the fiber surface of Bamboo paper is quite smooth. To describe the roughness more quantitatively, five random fibers were selected and measured from each kind of paper samples. The average root-mean-square roughness values of the wingceltis bark fibers and the other two fibers of Bamboo paper and Jingpi are calculated to be 1055, 497, and 745 nm, respectively, as shown in Fig.6(d). With respect to the plant fiber network, it follows Wenzel's relationship[27]:

cosθ * =rcosθ , (6)

where θ * is the apparent contact angle, θ is the contact angle on the flat surface and ris the ratio of the actual solid area over its projected one.

| Fig.6 AFM images: (a) Wingceltis bark fiber, (b, c) fibers composing Jingpi and Bamboo papers, (d) average root-mean-square roughness of the three fibers. |

The roughness analysis of the AFM images shows that the materials forming Qianlong Xuan paper are the roughest. The larger roughness enhances the wettability for hydrophilic Qianlong Xuan paper. Hence, good wettability and distinct capillary effects are accomplished. With regard to Jingpi whose contact angle is larger than Bamboo paper, other factors such as chemical constitution may play a leading role. Moreover, the large small-scale roughness may increase disordering in the short range thus contributing to the fluctuation in the small scale to improve the ink expression. As shown in Fig.1(b), the edge of Bamboo paper may result from the small roughness in the short range.

Qianlong Xuan paper, a representative of Chinese culture and civilization, has outstanding properties with important historical values. For Qianlong Xuan paper, perfect ink expression shows its good wettability and strong wicking. A high relative content of hydrogen bonding ratio and grooves along the central axis of bark fibers contribute to the good wettability. Better interconnectivity of the fiber network is due to more fibers overlapping and wide fibers, the homogeneous fiber distribution related to the raw material and a dispersing agent, smaller distance between overlapping fibers resulting from the denser fiber network, and the roughness of fiber surface concerned with sun bleaching make wicking strong and disordering in the short range increase; that is to say, natural materials combined with ingenious traditional processing technique endow Qianlong Xuan paper the unique performance. Compared to Qianlong Xuan paper, Bamboo and Jingpi ones have relatively weak wetting due to lower hydrogen bonding ration, more fillers, more non-uniform fiber arrangements, and smoother fiber surfaces, which makes ink expression slightly weaker. The improved manufacturing process will be of great benefit to the development of Xuan paper.

Prof. Xinglong Wu is currently a Deputy Dean of School of Physics of Nanjing University. He received his Ph.D. degree in 1994 from the Department of Physics of Nanjing University. His research is concerned with the preparation, microstructures and electronic/phonon properties of semiconducting nanostructured materials. He has co-authored over 280 scientific articles and filed 8 Chinese patents during the last 15 years. He has won 4 research-related national awards from Jiangsu province of China. He served as a member of the editorial board of Journal of Materials Science & Technology and other 3 international academic journals.

The authors have declared that no competing interests exist.

| [1] |

|

| [2] |

|

| [3] |

|

| [4] |

|

| [5] |

|

| [6] |

|

| [7] |

|

| [8] |

|

| [9] |

|

| [10] |

|

| [11] |

|

| [12] |

|

| [13] |

|

| [14] |

|

| [15] |

|

| [16] |

|

| [17] |

|

| [18] |

|

| [19] |

|

| [20] |

|

| [21] |

|

| [22] |

|

| [23] |

|

| [24] |

|

| [25] |

|

| [26] |

|

| [27] |

|