Dye-sensitized solar cells (DSSCs) are one of the most promising next-generation solar cells due to their advantages over other counterparts. The photoanode of DSSCs has a great effect on the photovoltaic performance. Traditional photoanode includes a bottom nanoparticle layer and an upper scattering layer for better light capture in longer wavelength. Mesoporous nanostructures with size comparable to the wavelength of visible light are considered to be excellent light scattering centers by providing extra places for dye loading. Developing a green synthetic method is of great importance. Herein we report a facile and surfactant-free synthesis of mesoporous rutile TiO2 submicrometer-sized spheres at temperature as low as 70 °C. DSSCs based on photoanodes with an upper scattering layer composed of as-obtained mesoporous spheres on nanoparticle dense layer demonstrate an 18.0% improvement of power conversion efficiency. This simple approach may offer an energy-efficient and environmentally friendly alternative for DSSCs fabrication.

Dye sensitized solar cells exhibit characteristics of low cost, easy fabrication, and relatively high power conversion efficiency (PCE) and these advantages over other photovoltaic devices render it a competitive candidate as one of the next generation power sources[1, 2, 3, 4, 5, 6]. Typical DSSCs consist of three parts: dye-sensitized TiO2 photoanode, Pt counter electrode, and iodide/triiodide redox electrolyte. Great efforts have been made to improve the performance of the DSSCs by tailoring the photoanode structures, developing novel dye molecules and Pt-free counter electrode, and optimizing the content of the electrolyte[7, 8, 9, 10, 11, 12, 13, 14, 15]. Among the factors affecting the PCE value, the structure and geometry of the photoanode is of great importance since it not only determines the dye loading and thus light harvesting ability but also provides an electron transport pathway which significantly influences the charge transport and collection efficiency.

Efficient DSSCs typically utilize TiO2 nanoparticles to form a nanoporous structure with a high surface area for dye loading. Recently, much attention has been devoted to one-dimensional nanostructures such as nanowires and nanotubes exhibiting direct electrical pathways for photogenerated electrons[16, 17, 18, 19, 20]. Nevertheless, the efficiency is limited by the insufficient surface area for dye loading. Meanwhile, the most widely used ruthenium dyes show much reduced light absorption in the wavelength range of 600-800 nm and nanosized TiO2 particles are poor scattering centers for light in the visible and near-infrared region, so that a considerable part of light can transmit directly through the thin film without being absorbed by dye molecules. By adding an upper scattering layer, the light harvesting ability of the photoanode can be largely enhanced. According to the Mie theory, nanostructures with a size comparable to the wavelength of visible light are suggested and scattering layers composed of different structures and morphologies have been widely investigated[21, 22]. However, introduction of large particles with low surface areas degrades the dye loading capacity of the photoanode and thus makes limited contribution to the photoelectron generation.

The incompatibility of the dye loading and light scattering efficiency can be resolved by using mesoporous sub-micron spheres with dual functions of satisfactory dye loading and scattering effect. A synthetic method of mesoporous beads by combining sol-gel and solvothermal process has been successfully developed by Chen, resulting in a high PCE of 8.84%[23]. Similar results have also been reported by Lee et al.[24] and Dai et al.[25]. Other synthetic strategies such as template assisted growth and electrochemical synthesis have also been reported to obtain the hierarchical TiO2 structures[26, 27, 28].

Unfortunately, above mentioned multi-step approaches are usually performed with participation of organic additives as chelating agents, concentrated alkaline solution or oxidizing precursors; thus, most of which are not environmentally friendly. Meanwhile, special conditions including solvothermal process, high-temperature calcination as well as a long reaction time are indispensible to complete the reaction and mainly responsible for an increase in the cost. So it remains a great challenge to develop a facile and green method to synthesize the hierarchical TiO2 structure. In traditional DSSCs configurations, anatase TiO2 has been mostly used for its excellent electrochemical performance. There are, as far as we are concerned, rare reports about mesoporous rutile nanostructures and their applications in DSSCs[29, 30]. Rutile TiO2, in fact, has some unique advantages over anatase, such as better chemical stability, higher refractive index, and lower cost[6].

Herein, we report a one-step, low-temperature synthesis of rutile TiO2 mesoporous submicrometer-sized spheres without surfactants and subsequent hydrothermal treatment. We also investigate their application in DSSCs as light scattering centers on top of a dense TiO2 nanoparticle layer.

Transparent TiCl4 aqueous solution (0.2 mol/L) was prepared by adding dropwise 2.2 mL pre-cooled TiCl4 into 100 mL ice water mixture under vigorous magnetic stirring. In the synthesis process, 50 mL TiCl4 aqueous solution (0.2 mol/L) was transferred into a beaker and treated in an electric oven at 70 ° C for 75 min. Then the beaker was taken outside the oven promptly and the white precipitants were collected by centrifugation at 6000 r min-1for 5 min at room temperature and washed with ethanol several times. Different reaction times of 60 min and 90 min were also used in the synthetic experiments with other experimental parameters being unchanged.

For the photoanode fabrication, a semitransparent thin film with an active area of 0.283 cm2 was printed on the TiCl4 pre-treated fluorine doped tin oxide (FTO) substrate (the substrate was immersed in 40 mmol/L TiCl4 aqueous solution at 70 ° C for 30 min and calcined at 500 ° C for 30 min) by doctor blade method with commercially available TiO2paste (Deysol, 18NR-T). Then the film was sintered at 500 ° C for 30 min to remove the organic solvent and designated as the reference film. The as-prepared mesoporous spheres (600 nm) were mixed with ethanol, ethyl cellulose, and alpha terpineol under magnetic stirring to get a viscous paste. Subsequently, the scattering layer with mesoporous TiO2 spheres was deposited through another doctor blade printing followed by a repeated sintering process. At last, the photoanodes were treated using 40 mmol/L TiCl4 aqueous solution at 70 ° C for 30 min and heat treatment at 500 ° C for 30 min. When the temperature dropped to 80 ° C, the photoanodes were immediately immersed in an ethanol solution containing N719 dye (Dyesol, 0.5 mmol/L) and sensitized for 24 h at room temperature.

A counter electrode was prepared by dipping one drop of HPtCl4 ethanol solution on a pre-cleaned FTO substrate with predrilled holes and annealing at 400 ° C for 20 min. To assemble the cell, a 60 µ m thick Surlyn film was sandwiched between the dye-sensitized photoanode and the counter electrode by hot pressing at 130 ° C for 16 s and electrolyte with 0.6 mol/L 1-butyl-3- methylimidazolium iodide (BMII), 0.02 mol/L I2, 0.01 mol/L tert-butylpyridine and 0.1 mol/L guanidinium thiocyanate in acetonitrile/valeronitrile (85/15 in volume) was injected through the holes. At last, the electrolyte was sealed inside with small squares of Surlyn film and a piece of microscopic objective glass.

The structural properties were characterized by X-ray diffraction (40 kV, 100 mA), scanning electron microscopy (SEM, Hitachi SU8010), and transmission electron microscope (TEM, Hitachi HT7700). X-ray photoelectron spectroscopy were carried out with instruments (ESCALAB 250) purchased from Thermo-VG Scientific. Reflection spectra and absorption spectra were measured in Shimadzu UV 3600 equipped with an integrated sphere. Dye loading amount of the photoanode was determined by measuring the light absorption of the desorbed dye from the photoanode in 0.1 mol/L NaOH aqueous solution. The current-voltage (J-V) test of the devices was performed with a Keithley 2400 source meter and a Newport simulated solar source which is calibrated to AM 1.5 (100 mW cm-2) by a standard silicon solar cell. A shading mask with an aperture larger than the active area was used during the measurement. The voltage was scanned from -0.3 V to 0.9 V with a step length and delay time of 10 mV and 30 ms, respectively. External quantum efficiency as a function of wavelength from 300 nm to 800 nm was measured with an IPCE measurement system (Newport) equipped with a 150 W Xe lamp. Electrochemical impedance spectrum was recorded by Autolab electrochemical workstation (PGSTAT 302N) under AM 1.5 at an open circuit (or in the dark) with the alternative signal amplitude 10 mV in a frequency range from 105 Hz to 0.1 Hz.

The morphology of the as-obtained products was characterized by SEM and TEM.Fig. 1(a) shows the SEM image of the as-synthesized monodisperse TiO2 spheres with an average diameter of 600 nm. The surfaces of the spheres are rough and composed of needle-like structures, whose formation is mainly due to the presence of Cl- ions in the precursor solution which can preferably adsorb and retard the growth of (110) surfaces[31]. X-ray diffraction peaks can be well indexed to the TiO2 rutile phase (JCPDS No.71-650). No other impurity phase can be detected, indicating that a pure rutile phase is obtained. The growth of rutile phase is ascribed to the high TiCl4 concentration since the hydrolysis of TiCl4 causes a highly acidic aqueous solution and such conditions favor the formation of rutile type nuclei[32, 33, 34]. The broadened diffraction peaks reveal a nanocrystalline structure and the size of needle shaped titania on the surface is in good agreement with the average crystalline size (~12 nm) calculated by XRD.

| Fig. 1. Characterization of the as-obtained products from synthesis of 75 min: (a) low magnification, (b) high magnification SEM, (c) TEM images, and (d) X-ray diffraction patterns. |

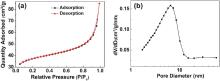

According to the N2 isotherms at 77.4 K shown in Fig. 2, the Brunauer-Emmett-Teller (BET) surface area of the as-synthesized spheres is 118.6 m2 g-1. The corresponding Barrett-Joyner-Halenda (BJH) pore size distribution suggests that the total pore volume is 1.31 cm2 g-1 with an average pore diameter of 7.3 nm. Further evidence of the mesoporous structure can be found from TEM image as shown in Fig. 1(c). Both the high-resolution TEM images (see supporting information) and XRD patterns indicate that the mesoporous spheres are well crystallized rather than amorphous, even though the synthesis temperature is only 70 ° C. The low-temperature synthesis can make a significant cost reduction in DSSCs fabrication. Meanwhile, the high surface area of the obtained rutile mesoporous spheres will be beneficial for dye loading and an average pore diameter of 7.3 nm is also adequate for diffusion of electrolyte ions when serving as the scattering layer in DSSCs.

| Fig. 2. (a) Nitrogen absorption and desorption curves and (b) BJH pore size distribution plot of the mesoporous spheres. |

Controlled experiments by varying the reaction time were performed. As shown in Fig. 3, the diameter of the obtained mesoporous spheres is only ~250 nm when the synthesis is continued for 60 min, compared to the 600-nm diameter for the 75 min reaction. An extended reaction up to 90 min yields larger spheres with an average diameter of ~750 nm. An even longer reaction time has little effect on the size of the mesoporous spheres. According to the La-Mer model for nucleation and growth kinetics of nanoparticles[35]and[36], the supersaturation condition is relieved after the formation of nuclei. Then the system begins the growth stage without forming additional nuclei and the existing nuclei increase in size. Both the narrow size distribution of the mesoporous spheres and the size dependence on the reaction time suggest that the growth process of the mesoporous spheres can be interpreted with the La-Mer model. It should also be pointed out that the synthesis of 60 min leads to a much lower yield compared with the prolonged reactions.

| Fig. 3. SEM images of submicrometer-sized spheres synthesized under different reaction time: (a, b) 60 min; (c, d) 90 min. |

We have fabricated two kinds of photoanodes: one contains only a nanoparticle layer and the other has a scattering layer on top (600 nm mesoporous spheres). The cross-sectional structure of the bilayered photoanodes was demonstrated by SEM. Fig. 4(a) shows that a thin layer of mesoporous spheres is evenly distributed on the surface of the TiO2 dense layer. The average thickness of the bottom TiO2 dense layer and scattering layer are about 11 µ m and 4 µ m, respectively. It is worthy to note that the bottom dense layer cannot be too thick because the negative effect from electron recombination will counteract the benefit of enhanced light absorption and carrier generation when the thickness is beyond the optimal value.

To investigate the scattering properties of the reference photoanode and bilayered photoanode, we measured the diffuse reflectance spectra using a Shimadzu UV 3600 spectrophotometer equipped with an integrating sphere. As shown in Fig. 4(b), several obvious differences can be found between the reflectance spectra. First of all, the reference photoanode fabricated with nanoparticles exhibits low reflectance in the visible range from 400 to 800 nm, suggesting that most of the visible light transmit through the film. With the upper scattering layer, the reflectance of the bilayered photoanode is much stronger than that of the reference photoanode, thus enhancing the light harvesting efficiency of the photoanode. The improved scattering properties are, on the one hand, attributed to the size of the mesoporous spheres comparable to the wavelength of visible light. On the other hand, the relatively high refractive index of rutile phase makes sure that a large part of light can be reflected back to the nanoparticles. Second, several reflection peaks in the visible range can be observed in the reflectance spectra of the bilayered photoanode. These reflection peaks are supposed to result from the difference of the refractive index between the scattering layer containing mesoporous spheres and the bottom nanoparticle layer. Third, the diffuse reflectance spectra of the bilayered photoanode undergo a red shift compared with the reference photoanode around the cut-off edge. We measured the UV-visible absorption spectra (Fig. 5) of the mesoporous spheres and the bandgap is fitted to be 2.98 eV, which is consistent with the rutile structure. The bandgap of rutile mesoporous spheres is smaller than that of anatase phase (3.2 eV) and this fact can account for the red shift phenomenon[28].

| Fig. 5. UV-visible absorption spectra of the rutile TiO2 mesoporous spheres. The absorption bandgap (2.98 eV) was extracted by fitting the curve near the absorption edge. |

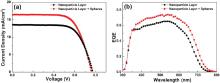

Fig. 6(a) presents the typical photocurrent density versus photovoltage curves of the DSSCs based on the reference and bilayered photoanode. The measured photovoltaic parameters of these solar cells are listed in Table 1. The control solar cells show a PCE of 7.15% with open circuit voltage (VOC) of 0.773 V, current density (JSC) of 13.5 mA cm-2, and fill factor (FF) of 68.2%. By adding the mesoporous submicrometer-sized spheres as a scattering layer, JSC is significantly enhanced to 16.4 mA cm-2 with VOC of 0.761 V and FF of 67.4%, leading to a PCE value of 8.43%. The efficiency enhancement arises chiefly from an increase in the photocurrent density. The improved JSC can be better understood from the incident photon to current conversion efficiency (IPCE) spectra, which contains detailed information about the light harvesting ability of the DSSCs. As shown in Fig. 6(b), an overall IPCE increase is observed by introducing a scattering layer, especially in the visible range from 500 to 800 nm, which is in good agreement with the increased light scattering efficiency of the bilayered photoanode. Another factor contributing to the enhanced JSC is the enhanced dye loading amount. According to the UV-vis measurement, there is a 24.3% increase of the dye loading for the bilayered photoanode compared with the reference photoanode since the scattering layer composed of mesoporous submicrometer-sized spheres provides extra place for dye adsorption.

| Table 1 Photovoltaic parameters of DSSCs with different photoanodes |

To further understand the influence of the scattering layer on the photovoltaic performance, we measured the electronic impedance spectra (EIS) of the corresponding DSSCs in the dark condition. As shown in the Nyquist plot (Fig. 7(a)), DSSCs based on the bilayered photoanode have a larger series resistance than the reference cell, which can explain why there is a slightly reduced FF for the former. Besides, the diameter of the first semicircle and the second one can be assigned to the charge transfer resistance at the Pt counter electrode and the redox electrolyte interface (R1), and the charge recombination resistance at the TiO2, dye and redox electrolyte interface (R2), respectively. Due to the identical method used in fabricating the Pt counter electrode and the same electrolyte, both the cells have a similar charge transfer resistance. However, cells based on the bilayered photoanode have a larger R2 value, which is favorable for the transport of electrons [37], [38]and[39]. Also, the maximum frequency (fmax) in the intermediate frequency regime shifts toward lower frequency as manifested by the Bode plot in Fig. 7b. According to the relation of τ = 1/2π fmax, where τ is the electron lifetime in the photoanode, a much longer electron lifetime and a lower charge recombination rate can be achieved for the bilayered photoanode. We also carried out the EIS measurement of the DSSCs at open circuit under AM 1.5 illumination. The DSSCs based on the bilayered photoanode has a longer electron lifetime, which is consistent with the result obtained in the dark. The improvement may be ascribed to the specific structural property of the mesoporous spheres. The porous structures are beneficial for the quick diffusion of the I3- ions in the electrolyte and the reduction of the local I3- concentration at the interface of electrolyte and TiO2, which can reduce the recapture of electrons in TiO2 conduction band. So it can be determined that the introduction of the mesoporous scattering layer on top of a dense TiO2 nanoparticle layer favors the electron transfer and suppresses electron recombination.

| Fig. 7. Electrochemical impedance spectra of DSSCs based on reference photoanode and bilayered photoanodes measured (a, b) in the dark and (c, d) under AM 1.5 illumination. |

It is generally accepted that VOC depends on the Fermi level of the photoanode and the redox potential of the electrolyte. The accumulation of electrons in the conduction band will affect the position of Fermi level. For example, the enhanced photocurrent density may raise the quasi Fermi level and consequently enhance the VOC to some extent. However, a lowered VOC is obtained by introducing the upper scattering layer even if there is an obvious increase in the photocurrent density. Similar results have also been reported in previous literature [29, 40]. We have also carried out the X-ray photoelectron spectroscopy (XPS) analysis of the mesoporous spheres and the corresponding electronic properties shown in supporting information are typical characteristics of TiO2rutile phase [41, 42]. Considering that the rutile mesoporous spheres have a lower conduction band position than anatase phase[6], it is believed that adding a scattering layer with rutile phase will shift the Fermi level of the photoanode closer to the redox potential and offset the VOC enhancement arising from the enhanced current density.

It is noted that the PCE of DSSCs in the present work is inferior to previous reports[43]. The impressive efficiencies were achieved by using products from high-temperature hydrothermal synthesis, whereas the mesoporous TiO2 rutile spheres used in our bilayered photoanodes as the scattering centers are prepared under low-temperature and surfactant-free conditions. In this configuration, the bottom nanoparticles dense layer with high specific surface areas is primarily responsible for dye adsorption and electron transport. The upper mesoporous spheres' layer can serve dual functions. Firstly, the size of the mesoporous spheres comparable to the wavelength of visible light enables them to exhibit an increased scattering efficiency and thus improves the light capture of the photoanode, which have been confirmed by the enhanced diffuse reflectance and IPCE spectra, respectively. Secondly, the high specific surface areas of the mesoporous spheres offer extra places for dye loading and more light can be absorbed, leading to the improvement in PCE. This simple green method may open up a new strategy for fabricating cost-effective and environmentally friendly DSSCs. Further optimizations are underway to realize highly efficient DSSCs.

In summary, mesoporous rutile TiO2 spheres with sub-micron size were synthesized through the hydrolysis of TiCl4 aqueous solution at ambient temperature of 70 ° C without adding surfactants. Scattering layer composed of such spheres on top of TiO2nanoparticle layer enables the bilayered nanostructure to possess pronounced light scattering efficiency and excess surface area for dye loading, leading to an improved conversion efficiency of 8.43%, compared to 7.15% for the reference nanoparticle solar cells.

Appendix. Supplementary material

The following is the supplementary data to this article:

We acknowledge the support from the National Natural Science Foundation (Nos.51422206, 51372159, 11304217), the 1000 Youth Talents Plan, the National Program on Key Basic Research Project of China (973 Program, No. 2015CB358600), the Jiangsu Shuangchuang Plan, the Project Supported by Jiangsu Science and Technology Committee for Distinguished Young Scholars (BK20140009) and funded by the Priority Academic Program Development of Jiangsu Higher Education Institutions (PAPD).

The authors have declared that no competing interests exist.

| [1] |

|

| [2] |

|

| [3] |

|

| [4] |

|

| [5] |

|

| [6] |

|

| [7] |

|

| [8] |

|

| [9] |

|

| [10] |

|

| [11] |

|

| [12] |

|

| [13] |

|

| [14] |

|

| [15] |

|

| [16] |

|

| [17] |

|

| [18] |

|

| [19] |

|

| [20] |

|

| [21] |

|

| [22] |

|

| [23] |

|

| [24] |

|

| [25] |

|

| [26] |

|

| [27] |

|

| [28] |

|

| [29] |

|

| [30] |

|

| [31] |

|

| [32] |

|

| [33] |

|

| [34] |

|

| [35] |

|

| [36] |

|

| [37] |

|

| [38] |

|

| [39] |

|

| [40] |

|

| [41] |

|

| [42] |

|

| [43] |

|