A γ-TiAl intermetallic alloy, Ti-45Al-2Nb-2Mn (at.%)-0.8 vol.%TiB2, has been processed from gas atomized prealloyed powder by field assisted hot pressing (FAHP). An initial analysis of the prealloyed powder helped on the understanding of the intermetallic sintering behavior. Atomized powder consisted of α metastable phase that transformed into α2+γ equilibrium phases by thermal treating. Different powder particle microstructures were found, which influence the microstructure development of the FAHP γ-TiAl material depending on the sintering temperature. Duplex, nearly lamellar and fully lamellar microstructures were obtained at the sintering temperatures above 1000 °C. Lower consolidation temperatures, below 1000 °C, led to the formation of an Al rich phase at powder particle boundaries, which is deleterious to the mechanical properties. High compressive yield strength of 1050 MPa was observed in samples with FAHP duplex microstructures at room temperature. Whereas nearly lamellar and fully lamellar microstructures showed yield strength values of 655 and 626 MPa at room temperature and 440 and 425 MPa at 750 °C, respectively, which are superior in comparison to similar alloys processed by other techniques. These excellent properties can be explained due to the different volume fractions of the α2 and γ phases and the refinement of the PM microstructures.

Titanium aluminides are important intermetallic alloys targeted for high temperature aerospace applications, namely the blades of low pressure turbines (LPT), because they can provide increased thrust-to-weight ratios and improve efficiency[1], [2], [3] and [4]. These blades must operate in aggressive environments at temperatures up to 750 ° C, where titanium aluminides possess reasonably good creep and oxidation behavior[5], [6] and [7]. It explains how such alloys have the potential to replace the heavier Ni-base superalloys currently used.

Two main approaches are currently being used in order to optimize the microstructure and mechanical properties by suitable alloy design and by choosing the proper processing route. Dual phase γ -TiAl alloys (γ -TiAl, tetragonal L10 structure and α 2-Ti3Al, hexagonal DO19 structure) exhibit various microstructures consisting of different volume fractions of equiaxed grains and lamellar colonies. Depending on their microstructure, they are classified as duplex, nearly lamellar and fully lamellar. Lamellar microstructures make the material more resistant to creep conditions, while equiaxed grain microstructures are more ductile at room temperature[8] and [9]. Even though, single phase γ -TiAl alloys possess better ductility due to L10 structure, they show strong plastic anisotropy, prone to embrittlement due to oxygen contamination and poor fatigue resistance[8], [9] and [10]. Therefore, extensive research has been carried out to achieve a two phase/multi phase microstructure (consisting γ -TiAl, α 2-Ti3Al and β /B2) by varying Al concentration in the range of 42-48 at.% and by other alloying additions such as Cr, Nb, W etc[11], [12], [13], [14], [15] and [16]. Addition of Cr, Mn and V leads to an increase in ductility, while Nb, W, Mo and Ta increases the high temperature oxidation resistance, creep resistance and high temperature strength. In addition, alloying with B leads to a microstructure refinement.

The most popular processing routes that have been explored so far are a combination of casting, thermomechanical and/or heat treatments and powder metallurgy (PM)[15], [17], [18], [19] and [20]. Even though, casting is the best established process, which suffers from several drawbacks such as choosing proper composition in order to obtain good melt fluidity, casting defects, segregation of alloying elements, poor workability, need for post consolidation, heat treatments, etc[19] and [21]. To overcome some of these drawbacks several new techniques such as counter-gravity and centrifugal casting techniques have been developed, even then these techniques heavily depends on the prior knowledge of the equilibrium phase diagram and further optimization of heat treatments[15]. Compared to the casting route, PM offers several advantages such as refining the microstructure, improving structural and chemical homogeneity and providing freedom of choosing composition and initial raw materials, reducing the need to separate heat treatments and directly obtaining final product shape requiring minimal post processing treatments. Particularly, a wide variety of PM routes have been considered to develop γ -TiAl intermetallics. Starting from prealloyed powder benefits the microstructural homogenization and the mechanical properties. γ -TiAl prealloyed powder could be obtained by different gas atomization techniques, such as plasma inert-gas atomization (PIGA), titanium gas-atomizer process (TGA) or electrode induction gas atomization (EIGA) among others[22]. Since the prealloyed γ -TiAl powder particles present a significant hardness, cold compaction is replaced by hot consolidation techniques. In addition, the processing time can be reduced by using newer techniques known as field activated sintering (e.g., spark plasma sintering) where simultaneous application of pressure and pulsed/continuous direct/alternating current is used[23] and [24]. It has been found that the effect of the current is the fast generation of internal heat by Joule effect which increases the sintering kinetics[25] and [26], providing a rapid densification of powders and minimal grain growth. Extensive research is currently going on to process various compositions, to understand microstructure evolution, mechanical properties and upscaling to produce actual components by using field activated sintering techniques[14], [19], [27], [28], [29], [30], [31], [32], [33], [34], [35] and [36].

In the current work, a commercial Ti-45Al-2Nb-2Mn (at.%)-0.8 vol.%TiB2 prealloyed powder has been sintered using one of the field activated sintering techniques known as field assisted hot pressing (FAHP), where simultaneous application of pressure and continuous alternating current is used. Different sintering temperatures have been selected to understand the microstructure development. Finally corresponding mechanical properties at room and elevated temperatures have been discussed.

Prealloyed powder (Ti-45Al-2Nb-2Mn (at.%)-0.8 vol.%TiB2) was employed as a raw material for the FAHP. The powder was gas atomized by EIGA at Helmholtz-Zentrum fü r Material und Kü stenforschung GmbH (Geesthacht, Germany)[22] and [37]. Powder size distribution was measured under a Mastersizer 2000 (Malvern, United Kingdom). X-ray diffraction (XRD) at room temperature was performed in a Philips Panalytical X'pert PRO MRD system (Almelo, The Netherlands) and intensity versus 2θ plots was acquired. In addition, the as-received prealloyed powder was analyzed by means of high temperature XRD at 600, 800 and 1000 ° C. High temperature XRD was performed under an X-ray diffractometer (Philips Panalytical X'Pert PRO MPD, Almelo, The Netherlands), fitted with a temperature chamber Anton Paar HTK 1200 (Graz, Austria). The microstructure was analyzed by scanning electron microscopy (SEM, Zeiss, EVO MA15, Jena, Germany) equipped with an energy dispersive spectroscopy (EDS) system (Oxford INCA x-act). Differential thermal analysis (DTA) was performed on a Setsys Evolution TGA & DTA/DSC (Setaram, France).

FAHP specimens were manufactured in a Gleeble 3800 equipment (Dynamic Systems Inc., USA), which allows physical simulation processing of materials. In this case, it was used to perform the pressing and sintering steps simultaneously, by applying a continuous low frequency alternate current to heat the material by Joule effect. The powder was poured into cylindrical graphite dies of 10 mm in diameter for the consolidation. An outside view of the Gleeble vacuum chamber with the gripped graphite die used for the processing was described in a previous work[38]. During processing, the temperatures were registered in the two punches and at the center of the die, where the thermocouple was placed at 1 mm above the surface of the sample. Initially, the graphite die was gripped at a load of 5 MPa inside the vacuum chamber and once the degassing temperature is overcome, the pressure is increased to 50 MPa. By observing the vacuum pressure, it was established that the degassing was stabilized at temperatures above 200 ° C. The γ -TiAl alloy has been processed by FAHP for a period of 2-10 min at different temperatures. The conditions were: FAHP1, 900 ° C-10 min; FAHP2, 1000 ° C-10 min; FAHP3, 1100 ° C-10 min; FAHP4, 1250 ° C-10 min; FAHP5, 1350 ° C-2 min. The heating rate was always 100 ° C/min, while the cooling rate registered was 140 ° C/min. Density of the consolidated samples was studied by Archimedes method.

Microstructural analysis of the FAHP samples was carried out by the equipments detailed previously and transmission electron microscopy (TEM). TEM analysis was performed under an FEI Instruments (Oregon, USA) Tecnai T20 TEM at 200 kV. The TEM foils were prepared by polishing the samples to a thickness of approximately 200 μ m, then punching 3 mm diameter disks, and finally thinning them using a Struers (Ballerup, Denmark) twinjet Tenupol-5 electropolisher until perforation. The electropolishing solution, which consisted of 5% perchloric acid, 35% butanol, 60% methanol, was held at a constant temperature of − 30 ° C and the voltage for sample preparation was 40 V.

Compression tests of the processed samples were performed under a constant strain rate of 10− 3 s− 1in vacuum at room temperature and 750 ° C in a Gleeble 3800 equipment. Compression samples had a cylindrical geometry with a length of 4.5 mm and a diameter of 3 mm. For high temperature tests, heating was programmed to be 10 ° C/min and a soaking time of 1 min was used after reaching 750 ° C. Changing the soaking time to 10 min did not resulted in any significant change in the mechanical properties. Nanoindentation analysis was carried out using a TI950 Triboindenter™ (Hysitron, Inc., Minneapolis, MN) and measurements were done under a constant load of 12 mN.

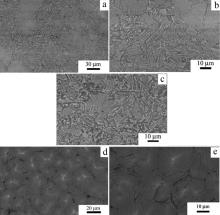

Fig. 1 shows the powder particle size distribution and the SEM micrographs of the powder showing its spherical morphology. The average particle size was of 51 μ m and the particle sizes measured at 10%, 50% and 90% of the total volume of the sample were 17.3, 51.2 and 117.8 μ m, respectively (Fig. 1(a)). As observed in Fig. 1(b-c), depending on the particle size, different powder microstructures are identified. It is a consequence of the size influence on the solidification rate at a constant cooling rate[22]. Small particles (< 50 μ m) (Fig. 1(b)), have a microstructure composed of a major volume fraction of dendritic and equiaxed grain morphologies, surrounded by a darker interdendritic regions and bright ribbons. However, bigger particles (> 50 μ m) (Fig. 1(c)), have a microstructure composed of dendrites that in some areas have grown into single and cluster of large grains, due to the lower solidification rates. In large particles, interdendritic channels with bright ribbons were also observed. In addition, brighter single phase regions are observed randomly inside the particles of different sizes (Fig. 1(d)) and they are composed of subgrains (Fig. 1(e)). The reason for the difference in varying microstructure contrast can be understood by studying the partitioning of different alloying elements in the dendrites and interdendritic regions. Literature analysis indicates that the solubility of Mn in α -Ti is lower compared to Nb[39], [40] and [41]. EDX analysis confirmed that a lower Mn and a higher Nb concentration were present in the single phase and dendritic regions resulting in the brighter contrast of these areas. Whereas, EDX analysis carried out at the interdendritic areas indicated a higher Al and Mn concentration consistent with the dark contrast. The bright ribbons are associated with the titanium borides as they are easily distinguished by their lacey morphology[42]. Regarding the relationship between the powder cooling rate and the microstructure, similar characteristics have been reported by Yang et al.[43].

'> | Fig. 1 (a) Powder particle size distribution and (b-e) backscattered (BSE) SEM micrographs showing the prealloyed powder microstructures for different particle's size: (b) 30 μ m in diameter, (c) 120 μ m in diameter and (e) 100 μ m in diameter; (d) single phase regions present in particles of different sizes. |

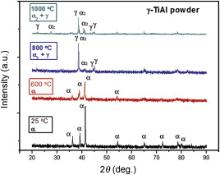

The XRD pattern at room temperature of the as-received prealloyed powder (Fig. 2) shows that the material mainly contains α -Ti3Al phase (a = 0.28175 nm; c = 0.46100 nm), which is consistent with the microstructures mentioned above ( Fig. 1(e)). The absence of the superlattice peak (2θ = 26.2° ) confirms that it does not correspond to the α 2 stable phase. The cooling rate reached during EIGA process is ∼105 K/s, which is slightly lower in comparison to that of rapid solidification process but higher than that of the conventional gas atomization [22]. Therefore, this cooling rate justifies the alloying elements and micro-constituents distribution observed in these microstructures, as well as, the detected α metastable phase and the absence of γ phase peaks. It is speculated that the interdendritic regions with a high amount of Al concentration might correspond to γ -phase but because the volume fraction is very small and the main peak is very close to the α -phase, it is difficult to detect in the current XRD profile.

| Fig. 2 XRD patterns of prealloyed Ti-45Al-2Nb-2Mn-0.8 vol.%TiB2 powder at 25 ° C, 600 ° C, 800 ° C and 1000 ° C. |

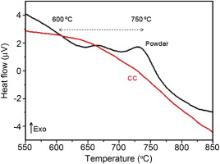

DTA analysis of the powder was done and compared with those of identical composition of (Ti-45Al-2Nb-2Mn (at.%)-0.8 vol.%TiB2) centrifugally-cast sample (Fig. 3). From the DTA of the centrifugally cast alloy, the phase transformation temperatures were identified and considered as reference:Teutectoid = 1150 ° C, Tα -transus = 1290 ° C, Tmelting = 1490 ° C. Comparing the powder and the as-cast DTA, it was observed that the thermal behavior was similar except for the temperature range between 600 ° C and 750 ° C ( Fig. 3). In order to understand the transformations happening in the powder at these temperatures, high temperature XRD was performed at 600, 800 and 1000 ° C and compared with the as-received powder XRD profile ( Fig. 2). The XRD pattern obtained from the powder at 600 ° C shows a decrease in the intensities of the α peaks. Increasing the temperature to 800 ° C leads to a greater decrease of α peaks combined with the appearance of γ -TiAl and α 2-Ti3Al peaks, suggesting that the α metastable phase started to transform into α 2+γ at around this temperature. Finally, at the highest temperature (1000 ° C), the transformation is completed and α 2+γ peak intensities are higher and clearly recognizable. Therefore, in order to achieve a complete transformation during consolidation of the previous α metastable powder, the sintering temperature must be equal or greater than 1000 ° C.

| Fig. 3 DTA analysis on the powder and the centrifugally cast Ti-45Al-2Nb-2Mn (at.%)-0.8 vol.%TiB2 alloy showing different thermal behavior at 600-750 ° C. |

The DTA analysis and the high temperature XRD patterns show consistent results. Transformations observed at 600-750 ° C in the DTA can be associated with those identified in the high temperature XRD. It seems that once the metastable powder is heated to temperatures above 800 ° C, stable γ phase appears and the rising temperatures leads to the stabilization of α 2+γ phases, according to the equilibrium phase diagram[26], [33], [44] and [45]. However, as shown in Fig. 4, heating the metastable powder to 800 ° C in the DTA and cooling, is not enough for the formation of lamellar structures consisting of α 2+γ phases. Therefore, either longer time or higher temperature are necessary.

The γ -TiAl prealloyed powder was processed by FAHP under the five different conditions mentioned above. Fig. 5 shows two representative curves illustrating the typical evolution of the temperature and displacement with respect to time recorded during the consolidation. From the punch displacement it can be observed that, for consolidation at temperatures around 900 ° C, the main densification must be reached during the first 5 min of the dwell (Fig. 5(a)). However, for higher processing temperatures (Fig. 5(b)), the displacement reveals a swelling and it could be interpreted as a result of the system dilatation[29]. The relative densities of the consolidated samples were found to be higher than 99% for all the processing conditions.

| Fig. 5 Typical evolution of the temperature and displacement versus time recorded in-situ during the FAHP processing at 900 ° C (a) and at 1000 ° C (b) during 10 min. |

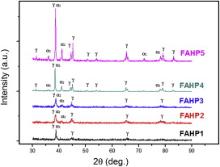

The XRD patterns corresponding to the FAHP materials (Fig. 6) show the presence α 2 and γ phases after consolidation at all the studied sintering temperatures and times. At higher processing temperatures, α 2+γ peaks become more intense and defined. Therefore, for all consolidation conditions, the metastable powder is transformed into α 2+γ phases and their volume fraction varies depending on the sintering condition, which is consistent with the high temperature XRD observations (Fig. 2).

shows BSE SEM micrographs of the material processed at 900 ° C (FAHP1) at various locations of the sintered compact. The micrographs at the center as well as near the edge shows a clear heritage of the former powder particle boundaries (Fig. 7(a, c)). Particularly, in the center of the sample a duplex microstructure can be observed (Fig. 7(b)). Then, the metastable and heterogeneous microstructure present in the as-received powder particles starts to transform into the equilibrium phases and homogenizes by diffusion at 900 ° C. Moreover, Fig. 7(b) shows the former single phase regions transformed into equilibrium lamellar colonies consisting of α 2 and γ phases. The different lamellae orientations correspond to the former equiaxed subgrains orientation identified in the single phase areas of the as-received powder (Fig. 1(e)). It is well known that an increasing of the processing temperature in these alloys entails a stabilization of α regions. Moreover, the consolidation of the intermetallic alloy at regions closer to the α -phase field promotes the formation of lamellar microstructures[45], [46], [47], [48] and [49]. Therefore, in the processing of FAHP1, lamellar microstructures first appear in the higher concentration α retained single phase regions. However, the lamellar colonies are surrounded by a high amount of equiaxed grains because the processing temperature might not be high enough to go through the eutectoid transformation and stabilize the α phase field.

In FAHP1, the densification is complete in the center, whereas a high concentration of pores are located near the edges (Fig. 7(c)), where the temperature measured by the die's thermocouple wasTFAHP1 = 900 ° C. It evidences a gradient of the temperature in the radial direction of the sample. Then, the optimum sintering temperature is not reached in the edges since the powder densification is just starting at this temperature and poor diffusion phenomenon has taken place in this area. However, the optimum densification in the center of the sample reveals an increase in the measured TFAHP1. This gradient in temperature has also been reported and modeled by other authors for similar hot consolidation processes such as spark plasma sintering[25] and [45]. Fig. 7(c) shows evidences of sintering and densification by the formation of sintering necks between particles. In particular, a close up view of these powder particle boundaries situated near the edge of the sample is shown in Fig. 7(d). The EDX analysis taken from points A, B and C was found to be 72%-75%Al, 23%-25%Ti, 1%-2%Nb, 1%Mn, indicating that the phase formed at this location is close to Al3Ti phase. In the field activated sintering processes the particle boundaries experience highest temperatures due to the generation of sparks or due to the high resistance for the current path and if sufficient time is employed mass transport takes place either by surface, grain boundary or volume diffusion. As the diffusion coefficients of Al in Ti and TiAl intermetallic are higher than that of Ti and other alloying elements [39], the elemental segregation to the particles surfaces can take place and promote the formation of Al enriched areas. The presence of interdendritic regions in the original powder particles with high concentration of Al could also serve as a source.

The gradient in density was not observed when the material was processed at 1000 ° C (FAHP2). BSE SEM micrographs in Fig. 8(a, b) show the duplex microstructure, composed of equiaxed grains and lamellar colonies along the whole sample. The lamellar colony average size was of 23 μ m. No pores or elemental segregation were observed throughout the sample. It suggests that processing at and above 1000 ° C allows a proper consolidation of the γ -TiAl alloy since the densification stage is well developed along the whole sample. A general view of this microstructure (Fig. 8(a)) still evidences the former powder particles and a microstructure similar to that observed in the center of the FAHP1 sample (Fig. 7(a)). In this condition, a gradient in the microstructure was not observed suggesting that when sintering was performed at 1000 ° C the entire sample was processed in the same phase field, below the eutectoid transformation[45], [46], [47], [48] and [49]. Therefore, sintering at temperature above 900 ° C and below the eutectoid point promotes a complete densification of the material with a duplex microstructure.

| Fig. 8 BSE SEM micrographs showing the duplex microstructure of the FAHP2 consolidated sample (a) with signs of former powder particles and (b) a combination of lamellar colonies and equiaxed grains. |

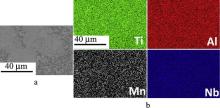

A nearly lamellar microstructure can be recognized in the center of the sample processed at 1100 ° C (FAHP3) (Fig. 9(a, b)). However, a radial gradient in the microstructure was again observed with a transition from nearly lamellar in the center (right in Fig. 9(c)) to duplex in the edge (left in Fig. 9(c)). A good distribution of the alloying elements is confirmed by EDS in these transition areas (Fig. 10). In this case, the gradient in the microstructure morphology along the sample's radial direction might be associated with the stability of the phases. As previously mentioned, according to the processing at different regions of the phase diagram, different microstructures will be formed[45], [46], [47], [48] and [49]. Therefore, during the FAHP3 processing, the real temperature of the material in the center of the sample might be higher and above the eutectoid point since higher volume fraction of lamellar colonies and no signs of former powder particles can be observed. However, in the edge of the sample, the sintering temperature (TFAHP3 = 1100 ° C) is below the eutectoid point and a duplex microstructure is recognized as occurred with FAHP1 and FAHP2.

'> | Fig. 9 BSE SEM micrographs showing the FAHP3 (a, b) nearly lamellar microstructure in the center of the sample and (c) the gradient in the microstructure along the sample's edges. |

| Fig. 10 (a) High magnification SEM BSE micrograph of the FAHP3 sample showing a duplex microstructure observed in a transition area within the microstructural gradient; (b) mapping analysis of the area, confirming a homogeneous distribution of the alloying elements. |

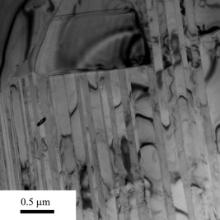

After processing the intermetallic at 1250 ° C (FAHP4), a nearly lamellar microstructure was found along the whole sample (Fig. 11(a-c)) with a refined lamellar colony of 9 μ m in size. Since the processing temperature is above the eutectoid point, α 2+γ phases will precipitate from α +γ phases following the equilibrium phase diagram and forming nearly lamellar microstructures[45], [46], [47], [48] and [49]. However, a small increase in the volume fraction of equiaxed grains was found in the edge (Fig. 11(c)) in comparison to the center (Fig. 11(a, b)). It suggests that in the center area of the sample, transformations start at temperatures closer to the α -transus, a more stable condition for the lamellar structure formation.Fig. 12 shows a TEM micrograph from the typical fine lamellar colony processed at 1250 ° C illustrating a lamellar width of 100-300 nm. Finally, through processing at 1350 ° C (FAHP5), fully lamellar microstructures were obtained (Fig. 11(d, e)) with a coarser lamellar colony of 27 μ m in size. It confirms that processing at temperatures above the α -transus helps to obtain microstructures completely composed of lamellar colonies and that increasing processing temperatures also leads to a growth in the average colony size. Nevertheless, thanks to the fast cooling rate provided by FAHP, as it has been observed in all the processed samples, the average lamellar colony sizes reached are significantly lower than those obtained by conventional casting[50]. In addition, brighter areas were found in FAHP5 material within the lamellar structure. These brighter areas, associated to heavier elements, might be related to possible retained β -phase as could be reached during these higher temperature conditions[51]. However, not significant predominance of β -phase is recognized as it is not identified in the corresponding XRD pattern (Fig. 6).

| Fig. 11 BSE SEM micrographs showing the FAHP4 (a, b) nearly lamellar microstructure along the whole of the sample and (c) edges areas with an increasing of the equiaxed grains volume fraction; FAHP5 (d, e) fully lamellar microstructure. |

| Fig. 12 TEM micrograph of the FAHP4 sample showing a fine lamellar colony. |

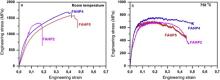

Duplex (FAHP2), nearly lamellar (FAHP4) and fully lamellar (FAHP5) microstructures were selected to analyze their mechanical behavior. Compression tests were carried out in these materials and its corresponding stress-strain curves are shown in Fig. 13 for room temperature and high temperature (750 ° C) conditions. The yield strength obtained at room temperature and high temperature for the FAHP2, FAHP4 and FAHP5 are 1058, 655, 626 and 303, 440 and 425 MPa, respectively. As expected, at room temperature tests higher yield points were obtained for the lowest processing temperature material (FAHP2), while the materials processed at higher temperatures (FAHP4, FAHP5) showed lower yield point values (Fig. 13(a)). Particularly, FAHP4, with a lower colony size average (10 μ m), exhibited higher yield point than FAHP5, with a higher colony size average (27 μ m). Therefore, as previously reported, duplex microstructures present higher strength than lamellar ones at room temperature under compression conditions[9]. FAHP resulted in higher yield point values than those obtained through SPS processing at higher processing temperatures with similar alloy compositions and microstructures[29] and [36]. For example, room temperature tensile tests of these reported works are as follows: a yield stress of 432 MPa for a Ti-48Al-2Cr-2Nb duplex alloy[36] and of 445 MPa for a Ti-47Al-2Cr-2Nb lamellar alloy[29]. In addition, other PM processing of similar alloys reported lower yield stresses values. That is the case of a Ti-48Al-2Nb-2Mn duplex alloy processed by EBM (electron beam melting) with a yield stress of 350 MPa[52] and a Ti-45Al-2Nb-2Mn near lamellar alloy processed by HIP at higher temperatures with a yield stress of 471 MPa[53]. However, FAHP2 duplex microstructures showed lower elongation-to-failure. This inferior strain values can be associated with the initial drop on its stress-strain FAHP2 curve (Fig. 13(a)) that might be due to an initial fracture of the more brittle Al3Ti phase that keeps surrounding powder particles during densification at 900 ° C, as previously explained. Similar phenomenon has been also reported in other SPS research works with Al and Fe[54] and [55], where depending on the phases present at the particle boundaries, the material exhibits either early failure or exhibits strain hardening resulting in greater ductility. Therefore, higher elongation-to-fracture might be expected if avoiding the more brittle phase in the particles boundaries, due to the fine FAHP2 duplex microstructure. The effect of the Al3Ti phase present at the particle boundaries on the mechanical properties is more visible when the compression tests were carried out at 750 ° C. As shown inFig. 13(b), before the yield point, the FAHP2 curve exhibits two slopes and the second slope varies in other samples tested under this condition. This is due to the different percentages of the Al3Ti phase. In the case of lamellar microstructures, FAHP4 exhibited again higher yield point than FAHP5, which might be related to its inherent refined microstructure. Similar to the room temperature yield strength values, the high temperature ones also exhibit superior to some of the reported ingot alloys (100-260 MPa, Ti-42Al-8Nb-0.2W-0.1Y)[16]. Even though the Ti-45Al-2Nb-2Mn-0.8 vol.%TiB2 alloy under the current processing conditions shows excellent mechanical properties in comparison to other alloys, the literature also indicates even better properties. Those instances are either due to the further refinement of the microstructure such as by mechanically milling/alloying processed alloys[32] and [35] or when controlled heat treatments were applied[21].

| Fig. 13 Compression tests stress-strain curves at (a) room temperature and (b) high temperature (750 ° C) conditions for FAHP2, FAHP4 and FAHP5 materials. X indicates that the test is stopped. |

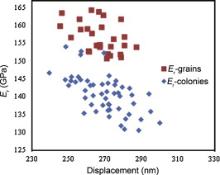

In order to establish the influence of the different microconstituents on the mechanical behavior, nanoindentation measurements were performed separately in the grains and in the colonies of a duplex microstructure (FAHP2). Fig. 14 shows differences observed in reduced modulus values between the grains and the colonies. This different behavior can be associated with a predominance of different phases present. According to the theory, the elastic modulus values of α 2 and γ phases areE(α 2) = 146 GPa and E(γ ) = 172 GPa, respectively [9], indicating that in the FAHP2 material the grain areas were mainly composed of γ phase and colony areas of α 2 phase, which fully confirms the above microstructural analysis.

| Fig. 14 Reduced modulus values of the different microconstituents obtained through nanoindentantion in the duplex (FAHP2) material. |

The results obtained from this study show that FAHP materials can be manufactured through an optimal microstructural control which can give the opportunity to develop appropriate microstructures depending on its application.

A γ -TiAl (Ti-45Al-2Nb-2Mn (at.%)-0.8 vol.%TiB2) intermetallic alloy has been processed by field assisted hot pressing, where simultaneous pressure and continuous alternating current were applied. The effect of the processing temperature was analyzed in order to understand the consolidation of the material and the phase transformations involved. In addition, the corresponding mechanical properties were analyzed. The following conclusions can be derived from the present study:

(1)

Prealloyed powder obtained by EIGA presents different microstructures depending on the particle size, and it is mainly composed of α -metastable phase. A phase transformation from α to α 2+γ phases occurs in the temperature range of 600-750 ° C.

(2)

γ -TiAl intermetallic alloy can be successfully consolidated at temperatures equal or higher than 1000 ° C developing duplex and lamellar microstructures. If the processing temperature is below 1000 ° C, there is a formation of Al3Ti phase at the particle boundaries, which is deleterious to the room temperature and high temperature mechanical properties.

(3)

Compressive yield strength values of 1050, 655 and 626 MPa were achieved for duplex, nearly lamellar and fully lamellar microstructures respectively at room temperatures. Whereas, at 750 ° C the nearly lamellar and fully lamellar microstructures exhibit yield strengths of 440 and 425 MPa, respectively. These excellent values are due to the refinement of the microstructure and its microconstituents.

(4)

Differences between the reduced elastic modulus of grains and colonies in a duplex microstructure suggest that a higher volume fraction of γ phase can be associated with the grains while a higher volume fraction of α 2 phase can be associated with the colonies.

The authors have declared that no competing interests exist.

| [1] |

|

| [2] |

|

| [3] |

|

| [4] |

|

| [5] |

|

| [6] |

|

| [7] |

|

| [8] |

|

| [9] |

|

| [10] |

|

| [11] |

|

| [12] |

|

| [13] |

|

| [14] |

|

| [15] |

|

| [16] |

|

| [17] |

|

| [18] |

|

| [19] |

|

| [20] |

|

| [21] |

|

| [22] |

|

| [23] |

|

| [24] |

|

| [25] |

|

| [26] |

|

| [27] |

|

| [28] |

|

| [29] |

|

| [30] |

|

| [31] |

|

| [32] |

|

| [33] |

|

| [34] |

|

| [35] |

|

| [36] |

|

| [37] |

|

| [38] |

|

| [39] |

|

| [40] |

|

| [41] |

|

| [42] |

|

| [43] |

|

| [44] |

|

| [45] |

|

| [46] |

|

| [47] |

|

| [48] |

|

| [49] |

|

| [50] |

|

| [51] |

|

| [52] |

|

| [53] |

|

| [54] |

|

| [55] |

|