In view of environmental and economic aspect, asphalt was modified with recycled packaging waste expended polystyrene (WEPS) instead of common polymer. The differential scanning calorimetry (DSC), rotational viscometer and dynamic shear rheology (DSR) were used to analyze and evaluate the viscoelasticity of modified asphalt. Results indicate that the sensitivity of modified asphalt to temperature is decreased while the rut resistance of asphalt is increased. In addition, the viscoelasticity of asphalt is improved after the modification with WEPS. Besides, the modified asphalt has high viscosity at low temperature and low viscosity at high temperature, which is favorable for construction.

Asphalt plays an important role in modern road traffic, especially in highway. The quality of asphalt has an influence on the road life and safety. Asphalt is a seamless and continuous road material with many advantages, e.g. smooth driving, facilitating conservation, less dusty etc. With the sustained development of China, there are growing requirements for road construction than ever before. The addition of large vehicles brings about increased traffic loads and severe overloading; and the current road asphalt cannot meet today's transportation requirements. Besides, China has a vast territory with widely diverse environmental conditions; high temperature maintains all year in some regions, while a large temperature gradient exists in some other regions, where a favorable high/low temperature stability of asphalt is necessary.

Asphalt is a complex mixture consisting of four components, saturates, aromatics, resins and asphaltenes. The pavement performance of modified asphalt can be improved by adding modifier into the original asphalt to change the components, structure and the viscoelasticity of asphalt. Modified asphalt is one kind of typical viscoelastic materials, and its dynamic shear rheological properties are close to the actual viscoelastic behavior, indicating that it is more adapted to test the actual usability of asphalt[ 1].

Viscosity or elasticity, or a combination of both of asphalt may occur, which relies on the temperature and proportion of each component of asphalt[ 2]. In recent years, many experts and scholars have used different methods to study the viscosity of polymer modified asphalt. Zhan et al.[ 3] measured viscoelastic parameters of asphalt, such as storage modulus, loss modulus and phase angle. Li et al.[ 4] investigated the needle penetration, softening point and ductility according to T-0606-2000, T-0604-2000 and T-0605-1993, and confirmed the optimal ratio of coal tar pitch modified asphalt through viscosity testing. Dongre et al.[ 5] proposed high-temperature evaluation parameter using η′ (kinetic viscosity) at 0.01 rad/s. In all these studies, only single/non-systematic method has been applied to evaluate the viscosity of modified asphalt.

As one of the commonly used packaging materials, waste expended polystyrene (EPS) offers shockproof packaging material in many fields, such as household appliances, instruments and electronic products[ 6]. However, the product is often disposable, resulting in serious threats to natural environment. Recovery of WEPS is a research hotspot all over the world. In this work, the asphalt base is modified with WEPS, and its viscoelastic property is analyzed.

The asphalt used in this study was conventional asphalt (90#), and its properties are shown in Table 1. WEPS was obtained from recycled TV's buffer packaging liner, and its properties are given in Table 2.

| Table 1. Properties of 90# asphalt |

| Table 2. Properties of recycled WEPS |

The WEPS was dried at room temperature after being cleaned, and then shaved into small particles with Komon knife (as shown in Fig. 1).

The asphalt was heated at 150 °C until it was fully melted and then a certain amount of WEPS (listed in Table 3) was slowly added. The mixture of asphalt with WEPS was heated to 190 °C, followed by manual stirring for 30 min and automatic stirring for 1.5 h with a JRJ 300-S digital shear emulsifying mixer (Shanghai Specimen Model Factory, China). The mixture was then cooled to 120 °C and kept for 30 min to disperse WEPS evenly in the asphalt.

| Table 3. Ratios of WEPS to based asphalt |

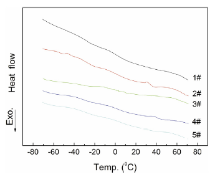

The differential scanning calorimetry (DSC) curves were obtained on a 2910 differential scanning calorimeter (US Ta Model) in the temperature range from -40 °C to 180 °C at a heating rate of 10 °C/min.

Rheological characteristics were examined with an AR1500ex dynamic rheological shear apparatus provided by Ta company, US.

Complex shear modulus ( G*), storage modulus ( G′), loss modulus ( G″), phase angle ( δ) were measured by a dynamic shear theometer. G* and δ can be used to characterize the viscosity and elasticity of modified asphalt[ 7],[ 8].

Viscosity was measured by using a Brookfield DV-II type rotary viscometer made in Middleboro of USA.

The DSC peak area forms direct ratio to all heat of reaction. It provides a chemical method to study the endothermic behavior of asphalt quantitatively because of high-precision and good reproducibility[ 9]. From a thermodynamic perspective, during the heating process three states are presented in asphalt, which are glassy, viscoelastic, and viscosity fluid state. The glass transition of asphalt, which is not a real thermodynamic second order transition, but a relaxation process of polymer or macromolecular chains, and viscous flow transition have a wide temperature range. As seen in Fig. 2, base asphalt has one absorption peak and the modified asphalt has two endothermic peaks. Zhang et al.[ 10] and [ 11] demonstrated that the endothermic peak reflects the extent of transformation in the aggregation, the ratio of solid to liquid and the viscoelasticity of asphalt. As WEPS is added, the absorption firstly goes down and then slightly goes up. Weaker absorption usually suggests better plasticity and thermal stability of asphalt[ 12]. The bigger absorption peak becomes, the microscopic properties of the asphalt components in this temperature range change more, and state interval occurs in more components, which include the crystalline component of the molten, the non-crystalline component of phase change and have an immense impact on macroscopic. The reason is that the high-speed mixing leads to the uniform disperse of WEPS in asphalt, as shown in Fig. 3. The WEPS can effectively absorb the wax in asphalt and remove the adverse effects of wax on the susceptibility of temperature and plasticity at low temperature.

3.2.1. Viscoelasticity of modified asphalt

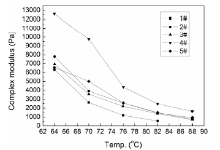

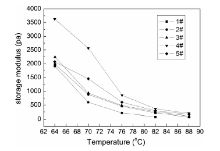

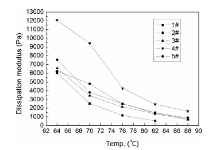

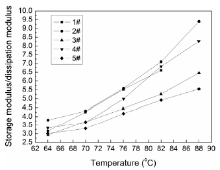

As shown in Fig. 4, Fig. 5 and Fig. 6, the G*, G′, G″ of modified asphalt and asphalt decrease dramatically as the temperature increases from 64 °C to 70 °C, which is due to the sliding motion of chain molecules induced by the thermal absorption of asphalt. The G* in viscoelastic material is bigger, the material gets harder, and the power required for overcoming the deformation of the material, which are caused by elastic deformation and unrecoverable elastic deformation, is bigger. The G*, G′, G″ of modified asphalt is higher than asphalt, indicating that the flexibility and anti-deformation ability of modified asphalt are improved. Such improvement can be attributed to the swelling of WEPS by absorbing light oil in the asphalt.

3.2.2. Variation of phase angle in modified asphalt

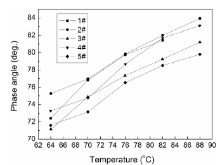

As shown in Fig. 7, the phase angle δ increases gradually when the temperature increases. The change is rapid in the temperature range of 64-76 °C and moderate in the range of 76-88 °C. Fig. 7 shows that the δ of modified asphalt is smaller than that of base asphalt at the same temperature except the asphalt modified with 3 wt% of WEPS. Under the same condition, the asphalt with smaller δ usually possesses more elastic composition and therefore shows stronger rutting resistance[ 13]. So, the rutting resistance of modified asphalt is better than that of asphalt. The aromatic compound, which plays a leading role in glue-soluble of asphalt, has increased after being modified. Besides, the aromatic compound is easy to be absorbed. This process regulates the relative content of asphaltenes and solvent in the asphalt system, indicating the improvement of viscoelasticity. After adding the modifier, different degree of crosslinking between modifier and asphalt may make the molecular of modified asphalt become larger. Molecule motion after crosslinking gets harder and flow temperature rises, which cause good viscoelasticity.

As shown in Fig. 8, at the same temperature, the tan δ of modified asphalt becomes smaller with increasing proportion of WEPS. Moreover, the tan δ value of asphalt modified with 2 wt% of WEPS is slightly greater than that of base asphalt. The asphalt modified with 4 wt% of WEPS has greater tan δ than all the other modified asphalt at temperatures ranging from 64 °C to 65 °C, but it decreases significantly and less than that of base asphalt in the temperature range of 65-80 °C, and changes gently after 80 °C. It demonstrates that the effect on asphalt modified by adding WEPS is not regular, which is related to its dispersion. There exist many chemical and physical differences (i.e. molecular weight, viscosity, density, polarity, difference of solubility parameter) between WEPS and asphalt. The WEPS and modified asphalt are mixed by mechanical thermal stirring. The WEPS particles do not dissolve in asphalt but can absorb soft matter in the asphalt.

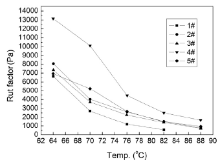

As shown in Fig. 9, for both asphalt and modified asphalt, the rut factor G*/sin δ decreases with increasing temperature and a sharp decrease in G*/sin δ occurs at 64-70 °C. Under the same thermal condition, the rutting resistance of WEPS-modified asphalt is correspondingly better than that of base asphalt. The base asphalt modified with 4 wt% of WEPS shows the best rutting resistance.

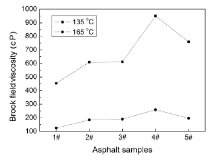

Asphalt binder mainly display viscous flow above the softening point, the most ideal flow pattern is Newtonian laminar fluid. However, most petroleum asphalt binder is non-Newtonian which is made up of molecules with different structure and weight. Flowability is determined by molecular structure and gravitational attraction with each other[ 14]. As shown in Fig. 10, at the same temperature, the viscosity of modified asphalt is higher than that of the asphalt. The difference in viscosity between asphalt and modified asphalt increases with decreasing the temperature, which is due to the change of asphalt from viscous flow state to viscoelastic state. The significant difference exists in the asphalt modified with 4 wt% of WEPS at 165 °C. In addition, the modified asphalt has a high viscosity at low temperature and a low viscosity at high temperature. Li et al.[ 15] demonstrated that such dependence of viscosity on temperature favors the pumping and mixing of asphalt during the construction process.

| Fig. 10. Viscosity of asphalt at 135 °C and 165 °C. |

The viscoelasticity of WEPS-modified asphalt are improved in this work. The absorption of heat decreases slowly after addition of modifiers. G*, G′, G″ and rutting resistance of WEPS of modified asphalt are higher than that of base asphalt, respectively, indicating the improvement of rutting resistance of modified asphalt. The viscosity of modified asphalt is greater than that of base asphalt, and the difference is more significant at low temperature.

Acknowledgments

The authors acknowledge the financial support provided by the National Natural Science Foundation of China (Grant Nos. 51002118, 51172180), Program for New Century Excellent Talents in University of Ministry of Education of China (Grant No. NCET-12-1045) and Shaanxi Programs for Outstanding Youth Project (2011).

| 1. |

|

| 2. |

|

| 3. |

|

| 4. |

|

| 5. |

|

| 6. |

|

| 7. |

|

| 8. |

|

| 9. |

|

| 10. |

|

| 11. |

|

| 12. |

|

| 13. |

|

| 14. |

|

| 15. |

|