Tensile tests and notch toughness tests were conducted on Zr61Ti2Cu25Al12 glass (ZT) at room temperature and liquid-nitrogen temperature. The tensile strength of ZT was improved from 1.63 GPa at room temperature to 1.72 GPa at liquid-nitrogen temperature. Micro-notches with a root radius of 1–3 μm were introduced to test the notch toughness of ZT at room temperature and liquid-nitrogen temperature. The test results revealed that the notch toughness of ZT at liquid-nitrogen temperature is comparable to that of ZT at room temperature. The combination of high yield strength and notch toughness of ZT at liquid-nitrogen temperature is comparable to that of the best cryogenic engineering materials.

Lightweight and high-performance cryogenic engineering structures require materials with a combination of high strength and high fracture toughness [1]. The reduced thermal activation at cryogenic temperatures typically produces increased strength [2]. However, a ductile-to-brittle transition on cooling often occurs in widely used structural materials such as body-centered cubic carbon steels and hexagonal close packed Ti alloys [1] and [3]. This reveals an inherent difficulty in combining both high strength and high toughness for cryogenic engineering applications. Although a variety of materials exist with strength and toughness that are weakly temperature-dependent (e.g. Ni steels with fine grain size, face-centered cubic stainless steels, Ni-based superalloys, Al alloys and Cu alloys) and are used in cryogenic engineering structures [1], a long-standing goal remains the combination of high strength and high fracture toughness at cryogenic temperatures. Since both the yield strength and ductility of nanostructured metals and alloys can be significantly improved at cryogenic temperatures compared with room temperature [4] and [5], an inverse temperature-dependent toughness results [3]. However, some BMGs such as Ti40Zr25Cu12Ni3Be20 glass [6], Pd79Ag3.5P6Si9.5Ge2 glass [7], and Zr61Ti2Cu25Al12 glass [8] (ZT) are much more damage-tolerant than nanostructured metals and alloys at room temperature and their combination of high yield strength and fracture toughness extend well beyond the traditional limit ranges established by the strongest and the toughest materials. Furthermore, both strengthening and ductilization of bulk metallic glasses (BMGs) at cryogenic temperatures have also been reported [2], [9], [10], [11], [12], [13] and [14] due to retarded shear banding. Other work has shown reductions in shear-band viscosity, shear-slip velocity, and the magnitude of stress drop in serrated flow, with decreasing temperature [12] and [13]. These observations imply that some BMGs might combine sufficiently high yield strength and high fracture toughness at cryogenic temperatures.

Previous work has shown that ZT [8] and [15] exhibits a combination of high yield strength and high fracture toughness at room temperature, comparable to the best structural materials known [8]. The present work further shows that the strength of ZT increases slightly at liquid-nitrogen temperature (77 K) with notch toughness that is comparable to that obtained at room temperature. These results reveal an excellent combination of toughness and strength of ZT at 77 K.

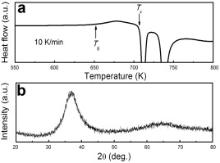

Zr61Ti2Cu25Al12 [15] master alloy ingots were prepared by arc melting pure elemental pieces under Ti-gettered argon atmosphere in a water-cooled copper hearth. The ingots were flipped and re-melted 4 times to ensure chemical homogeneity. Zr61Ti2Cu25Al12 glassy rods with a diameter of 5 mm and plates with dimensions of 3.2 mm × 8 mm × 62 mm were fabricated by suction casting method using water-cooled copper mold. The fully amorphous nature of the ZT samples was confirmed by the diffuse X-ray diffraction pattern (Scintag X-1 X-ray diffractometer) and DSC traces (Perkin–Elmer DSC-7) as shown in Fig. 1. Tensile testing was conducted on samples with gage dimensions of Φ 1.5 mm × 10 mm that were machined from as-cast rods and polished with SiC papers. Bend bars for toughness testing with dimensions of 3 mm × 6 mm × 26 mm were cut from the bottom part of as-cast plates with a low-speed diamond blade and polished with SiC papers. Single edge notches with a length of 2.8 mm were introduced using a diamond wire saw with a radius of 100 μm. Micro-notches, with a root radius of 1–3 μm were obtained by repeatedly sliding a diamond-coated razor blade over the saw-cut notch with lubricant. The final depth of the notch is 3 mm. Toughness tests and tensile tests were conducted at room temperature and liquid-nitrogen temperature on an Instron 1361 electromechanical machine at a displacement rate of 0.3 mm min-1 and an initial strain rate of 5 × 10-4 s-1 respectively. The cryogenic temperature tests were conducted by immersing the samples into liquid nitrogen.

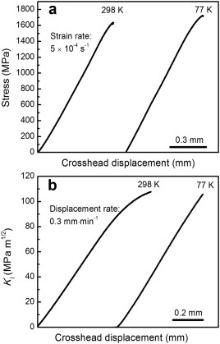

Fig. 2(a) shows the tensile engineering stress-crosshead displacement curves for ZT at 298 K and 77 K, respectively. It is proposed [16] that more elastic energy is needed to activate shear-transformation zones at cryogenic temperatures than at room temperature. In the present work, the yield strength increased from 1.63 GPa at 298 K to 1.72 GPa at 77 K (as listed in Table 1). Compared to the reported 18% strength improvement for Zr50Cu40Al10 and Zr59Cu31Al10 BMGs [10], the 5.5% increase for ZT is low. However, the improvement of strength of ZT is larger than that of Cu57Zr43 BMG which exhibited a strength increase of only 1.5%. In contrast to the compressive ductility improvements reported for other BMGs at cryogenic temperatures [9], [12] and [13], there is no obvious tensile ductility of ZT at either room temperature or 77 K, similar to that found for other BMGs in the literature [10], [17] and [18]. In the uniaxial tensile stress state, there is no frictional force that is available in compression. The tensile stress state enhances strain softening and the instability of shear bands, producing a shear band that slips without limit. Even though it has been reported that both the viscosity and velocity of shear banding are reduced at cryogenic temperatures [12] and [14], the tensile ductility of BMGs at cryogenic temperatures has not yet been be remarkably improved.

| Table 1. Measured yield strength ( σy), fracture toughness of micro-notched sample ( Kc) and calculated plane stress plastic zone size ( rp) of ZT at room temperature (298 K) and liquid-nitrogen temperature (77 K) |

As shown in Fig. 3(a), a micro-notch with root radius of 1–3 μm was introduced by using a diamond-coated razor blade to investigate the notch toughness of ZT at 77 K. The loading traces of the toughness tests for the micro-notched samples tested at 298 K and 77 K are shown in Fig. 2(b). As listed in Table 1, the toughness of the micro-notched sample is 107.7 MPa m1/2 at 298 K. As reported elsewhere, the room temperature toughness of fatigue pre-cracked samples [15] is 112 MPa m1/2. We have obtained a room temperature fatigue pre-cracked toughness of 114.8 MPa m1/2 for this material. As demonstrated presently, the micro-notch toughness of ZT at room temperature is very similar to the toughness values obtained at room temperature on fatigue pre-cracked samples. This type of behavior has been reported previously on very tough metallic glass samples [6] and [15] where the proliferation of shear bands at the fatigue pre-crack essentially blunts the fatigue pre-crack. This has also been demonstrated in other work on ZT [15] and is consistent with that found in the present work. However, BMGs with lower toughness have shown quite different behavior regarding the effects of changes in notch radius on the toughness [19], [20], [21] and [22]. In those cases, the toughness increased from 18.4 MPa m1/2 for fatigue pre-cracked samples to 256 MPa m1/2 for notched samples with notch root radius [21] of 1 mm. Differences in the magnitude of the effect of changes in notch radius on the toughness have similarly been reported for a variety of crystalline structural materials, as reported elsewhere [20] and [21]. Crystalline metallic materials generally show a less dramatic increase in toughness with increasing notch radius [20] and [21]. The micro-notch toughness of ZT is similar to that obtained on a fatigue pre-cracked sample. This suggests that such micro-notched samples can be used to approximate the fatigue pre-cracked toughness.

Interestingly, the toughness of the micro-notched sample tested at 77 K (i.e. 105.8 MPa m1/2) is also comparable to that obtained at room temperature (i.e. 107.7 MPa m1/2, Table 1). As shown in Fig. 2(b), more nonlinearity is present in the stress intensity factor vs. crosshead displacement curve at 298 K than 77 K, implying that more extensive plastic deformation occurred at 298 K as shown in Fig. 3(b). Fig. 3(c) also clearly shows significant shear banding and crack bifurcation from the razor notch at 77 K, while Table 1 provides calculations for the plane stress plastic zone size ( rp = ( Kc/ σy)2/2π) using the presently determined values for Kc and σy. The final fracture toughness of the samples tested at 298 K and 77 K were very similar and thus the calculated plane stress plastic zone sizes are also similar.

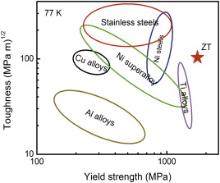

The key observations regarding the present ZT relate to the combination of excellent toughness and strength (i.e. >1.6 GPa) in this material at room temperature, as well as the lack of any significant decrease in these values on going to liquid-nitrogen temperature. The lack of a ductile-to-brittle transition in such a high strength material is remarkable. In order to put this combination of properties into perspective, the excellent combination of strength and notch toughness of ZT at 77 K was compared with currently available data of cryogenic engineering materials in an Ashby type diagram shown in Fig. 4. While the data for the crystalline structural materials reported in Fig. 4 utilize values for KIC obtained on fatigue pre-cracked samples in many cases, the present work on ZT reveals essentially similar values for notch toughness and fatigue pre-cracked toughness at room temperature, and very little change in the notch toughness on going to 77 K. The fact that ZT is somewhat strengthened at 77 K without any significant loss in notch toughness places this material at the position in Fig. 4.

| Fig. 4. Ashby plot of yield strength versus fracture toughness of cryogenic engineering materials at 77 K. Yield strength and fracture toughness data for Ni steels [1] and [25], Ti alloys [1], [26] and [27], and other cryogenic engineering materials [1] and [28] are collected from the literature. For comparison, data for ZT are designated by a red star. |

The excellent combination of strength and toughness along with the lack of a ductile-to-brittle transition of the present BMG appears to be unique. Previous work on Vitreloy I has similarly shown little effect of cryogenic conditions on the strength/toughness combination, but at much lower values of fatigue pre-crack toughness [21] compared to the present material. Although the notch toughness values for Vitreloy I are considerably inflated above that of the fatigue pre-cracked values, other work has also shown these elevated notch toughness values to be unaffected by cryogenic temperatures [21] as well as impact loading conditions [23]. Most recent work on Ni–Ta– X BMGs has similarly shown little effects of changes in test temperature on the notch toughness, although again at much lower values of absolute toughness [24].

The effects of cryogenic temperature on the strength and micro-notch toughness of ZT have been determined. While notch toughness testing appears to provide very similar values to fatigue pre-cracked values for room temperature toughness for ZT, cryogenic temperature slightly increases the strength without measurably degrading the micro-notch toughness. This confirms that the combination of strength and notch toughness of ZT is excellent at liquid-nitrogen temperature.

References

This work is supported by ARO-W911NF-12-1-0022 with partial support from DTRA-1-11-1-0064. The authors appreciate Chris Tuma from Advanced Manufacturing and Mechanical Reliability Center for help in mechanical tests.

| 1. |

|

| 2. |

|

| 3. |

|

| 4. |

|

| 5. |

|

| 6. |

|

| 7. |

|

| 8. |

|

| 9. |

|

| 10. |

|

| 11. |

|

| 12. |

|

| 13. |

|

| 14. |

|

| 15. |

|

| 16. |

|

| 17. |

|

| 18. |

|

| 19. |

|

| 20. |

|

| 21. |

|

| 22. |

|

| 23. |

|

| 24. |

|

| 25. |

|

| 26. |

|

| 27. |

|

| 28. |

|