A large-sized CuZr-based bulk metallic glass (BMG) composite with enhanced mechanical properties is prepared successfully. With the addition of Ta to CuZr-based alloys, the critical composite size changes and the microstructure diversifies. The composite with 0.5 at.% Ta addition has the largest critical size with the microstructure of single CuZr(B2) phase uniformly dispersing in amorphous matrix. This composite exhibits good mechanical properties, i.e., large compressive plasticity and work-hardening ability, which should be attributed to the uniformly distributed CuZr(B2) phase. The increased critical size of CuZr-based BMG composite can be explained by the fact that proper Ta addition can suppress the precipitation of crystalline phases other than B2 CuZr phase during solidification. This study may be helpful for the fabrication of large-sized BMG composites with excellent mechanical properties.

Bulk metallic glasses (BMGs) have attracted great attention owing to their unique properties compared with their crystalline counterparts, such as high strength, high hardness, large elastic strain limit and good corrosion resistance [1], [2], [3], [4] and [5]. However, the monolithic BMGs usually exhibit typical room-temperature brittleness and strain-softening phenomenon [6], [7] and [8], which have strictly limited their applications as structural materials. Recently, BMG composites (BMGCs), especially those with in-situ crystalline phases, have been prepared to circumvent some of these weaknesses of monolithic BMGs and several classes of BMGCs with excellent properties have been developed successfully [9], [10], [11], [12], [13], [14], [15], [16] and [17]. The plasticizing mechanism involved is that the ductile crystalline phases embedded in the glassy matrix can hinder the propagation of shear bands and lead to their multiplication effectively during deformation. Among them, the meaningful combination of pronounced compressive plasticity and macroscopic work-hardening ability was obtained by the introduction of CuZr(B2) phase into the amorphous matrix in the CuZr-based BMGCs. And the crystalline phase may undergo the martensitic transformation from B2 to B19′ phase during deformation [18], [19], [20], [21], [22], [23] and [24].

In recent years, CuZr-based BMGCs have been studied widely due to their enhanced tensile properties and work-hardening ability [21] and [25]. Besides the mechanisms of their formation and deformation, the adjustment of their microstructure has also been studied systematically [19], [20], [21], [22], [23], [24], [25] and [26]. But the limited cast dimension of BMGCs is still a stumbling block and severely restricts their applications. Although previous reports about pinpointing the formation of BMGCs may provide some meaningful guidance [27], the dimension of composite samples, containing CuZr(B2) as the single precipitated crystalline phase in the amorphous matrix, is still in millimeter scale. Hence, an increase in the dimension of CuZr-based BMGCs with excellent mechanical performance is required to promote their potential engineering applications.

In this paper, we present the effect of Ta addition in Cu–Zr–Al–Sn quaternary system on improving the critical size of BMGCs while maintaining CuZr(B2) as the single embedded crystalline phase simultaneously. Centimeter-scale CuZr-based BMGCs with superior compressive property were synthesized successfully. This is expected to shed light on the composition design and preparation of novel large-scale BMGCs with excellent mechanical properties and facilitate the structural applications of the BMGCs.

Alloy ingots with nominal compositions of Cu46.15-0.5 xZr45.35-0.5 xAl7.5Sn1Ta x (0 ≤ x ≤ 0.9, at.%) were prepared by arc-melting mixtures of constituent elements (purity > 99.9%) under a Ti-gettered high-purity argon atmosphere. To ensure the compositional homogeneity, pre-alloys of elements Ta and Zr, which have relatively high melting points and large solubility at high temperature, were prepared firstly. The mixtures of pre-alloys and the other pure metals were then remelted for five times. Ribbons and rod samples were prepared through melt spinning and tilt casting, respectively. And the induction melting method was used in both processes to melt the alloy pieces.

The phase structure of the as-cast rods was determined by X-ray diffraction (XRD: Bruker AXS D8) with a Cu Kα radiation ( λ = 0.1541 nm). Microstructure of the samples was analyzed by electron probe microanalysis (EPMA: JEOL JXA 8100) using the BSE mode. Volume fraction and size distribution of crystalline phases in the composites were estimated according to the images of the cross-section surfaces [21] and [25]. Compositions of the phases were determined under an energy dispersive spectrometer (EDS). Detailed structure was examined by transmission electron microscopy (TEM), using a JEM 2100F instrument equipped with a field emission gun. The samples for this study were mechanically polished to ∼50 μm thick and then electropolished using a mixed solution of HNO3 and CH3OH with a volume ratio of 1:3. Thermal properties, mainly about the behaviors of glass transition and crystallization of glassy ribbons were measured with a differential scanning calorimeter (DSC: NETZSCH 404 C) at a heating rate of 0.33 K/s. Melting and cooling processes of the master alloys were examined as well. Mechanical properties of the 1-cm-diameter samples were characterized through uniaxial compression test on the large-sized samples at a strain rate of 2.08 × 10-4 s-1 at room temperature. Scanning electron microscopy (SEM: CS3400) was used to examine the fracture surfaces.

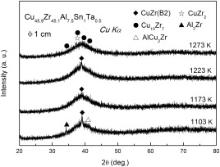

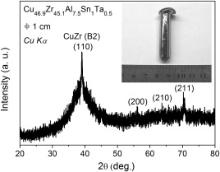

To investigate the influence of composition fluctuation on the constitution of precipitated phases in the CuZr-based alloys, 1-cm-diameter cylindrical rods with different Ta contents were prepared and examined. As shown in Fig. 1, less than 0.3 at.% or more than 0.7 at.% Ta addition will cause the precipitation of some detrimental intermetallic compounds, such as CuZr2 and Cu10Zr7 phases. These compounds may be harmful to the mechanical properties and result in the catastrophically brittle fracture under uniaxial stress. For the sample with 0.5 at.% Ta addition, only CuZr(B2) phase can be identified in the XRD pattern, as shown in Fig. 2. The inset of Fig. 2 is the appearance of the 1-cm-diameter sample. Hence, we can probably come to a conclusion that 0.5 at.% Ta addition can lead to the precipitation of single CuZr(B2) phase during the casting process at the present cooling rate.

| Fig. 1. XRD patterns of the as-cast 1 cm-diameter rods for Cu46.15-0.5 xZr45.35-0.5 xAl7.5Sn1Ta x ( x = 0, 0.1, 0.3, 0.5, 0.7, 0.9 at.%). |

| Fig. 2. XRD pattern of Cu45.9Zr45.1Al7.5Sn1Ta0.5 (Inset: the appearance of the 1-cm-diameter sample). |

The difference in precipitated phases can also be confirmed by the SEM images. As shown in Fig. 3(a) and (b), the Ta-free sample contains CuZr(B2) phase (in dark gray), and some white dendrites uniformly distributed throughout the sample. Besides, some black phase exists irregularly with the composition of Zr46.08±0.66Cu46.65±0.20Al7.28±0.54. The formation of these phases may be attributed to the cooling rate fluctuation in different parts of the samples during casting. Under the circumstance of more Ta addition (0.9 at.%), only a small amount of CuZr(B2) phase precipitated in the matrix, as presented in Fig. 3(c) and (d). Besides, excessive Ta addition induces the formation of packed crystalline phases near the center of the samples, whose distribution and size vary greatly throughout the composites. Therefore excessive Ta addition will weaken the glass-forming ability of the matrix alloys in this Cu–Zr–Al–Sn quaternary system seriously and lead to the precipitation of some detrimental phases.

| Fig. 3. Microstructure of samples with different Ta addition: (a) 0, (b) 0, partial enlarged image, (c) 0.9 at.%, edge region, (d) 0.9 at.%, central part, (e) 0.5 at.%. |

In comparison with the samples mentioned above, the microstructure of the Cu45.9Zr45.1Al7.5Sn1Ta0.5 alloy is relatively uniform. As shown in Fig. 3(e), spherical crystalline precipitates with diameters between 2 μm and 350 μm, which can be identified as the CuZr(B2) phase, are embedded uniformly in the featureless amorphous matrix (in light gray). The size distribution of the crystalline phase in this sample was revealed to be bimodal-like. The average diameter and volume fraction of the second phase can be determined as 52 μm and 32%, respectively.

TEM analysis was carried out in order to investigate the detailed structure of the precipitated phase and its beneficial effects on the mechanical properties. Fig. 4(a) shows the interface between the spherical phase and the amorphous matrix. Nanoscale crystals exist near the interface. The selected area electron diffraction (SAED) patterns (as shown in the inset) clearly show the typical halo ring of amorphous structure as well as the [001] zone axis diffraction of the CuZr(B2) phase. Fig. 4(b) shows that there are many sub-boundaries in the spherical CuZr(B2) phase. Compared with nanoscale crystals, such microscale spherical crystals can hinder the propagation of the shear bands effectively. Furthermore, the sub-boundaries full of defects (as shown in Fig. 4(c)) are suggested to be favorable for the nucleation of martensitic phase, and may make the martensitic transformation of CuZr(B2) easier to happen under stress.

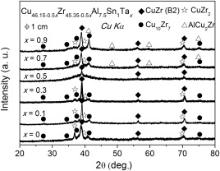

Casting temperature is an important factor affecting the kind, volume fraction and distribution of the precipitates in the alloys. In this research, the effects of different casting temperatures for the alloy containing 0.5 at.% Ta were also examined. An infrared thermometer was used to measure the casting temperature through the observation window of the high frequency induction furnace. The XRD patterns of Cu45.9Zr45.1Al7.5Sn1Ta0.5 samples casted at different temperatures are shown in Fig. 5. It is seen that the optimal casting temperature to ensure the precipitation of single CuZr(B2) phase in the amorphous matrix is ∼1223 K. At higher or lower temperature, other detrimental phases will precipitate in the amorphous matrix.

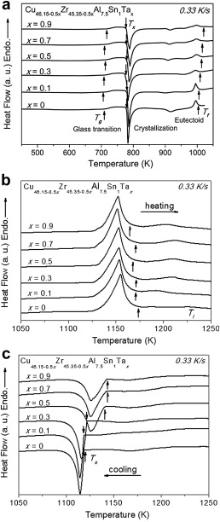

To investigate the mechanism for the formation of large-scale BMGCs, characteristic temperatures of the ribbon samples with different Ta contents are measured by DSC under continuous heating process, and the corresponding curves are presented in Fig. 6(a). It turns out that the thermal behaviors keep almost unchanged with the addition of Ta. All these samples display a glass transition process followed by the crystallization and the eutectoid transformation of the crystalline phases from the equilibrium phases at low temperatures to the CuZr(B2) phase.

The melting and cooling processes of the master alloys were also measured and the curves are shown in Fig. 6(b) and (c). The liquidus temperature Tl decreases while the solidification temperature Ts increases with the increase of Ta content. All the characteristic temperatures are given in . Tf represents the offset eutectoid temperature of the CuZr(B2) phase. Trg is the reduced glass temperature, which is equal to Tg/ Tl; γ is a thermal parameter which is usually used to evaluate the glass-forming ability of alloys, γ = Tx/( Tg + Tl). K, which can be expressed as K = Tf/ Tl is a parameter proposed to evaluate the forming tendency of the CuZr(B2) phase in the metastable CuZr-based alloys in terms of the competition among the vitrification, the precipitation of metastable CuZr(B2) phase and room-temperature equilibrium phases during quenching. Song et al. also pointed out that a larger K usually corresponds well with the easy formation of the CuZr(B2) phase in the CuZr-based BMGC [27].

| Table 1. Thermal parameters of the Cu46.15-0.5 xZr45.35-0.5 xAl7.5Sn1Ta x samples with different Ta additions (0 ≤ x ≤ 0.9) |

In this study, no definite relations can be identified among the parameter K as well as the other characteristic temperatures and the critical size of the samples with the change in the content of Ta. That is to say, in the present study, thermal properties may be not enough to reveal the reason for this size improvement. However, it is seen that appropriate amount of Ta addition can inhibit the precipitation of other crystalline phases besides the CuZr(B2) phase and increase the available size of the BMGC containing CuZr(B2) as the single crystalline phase.

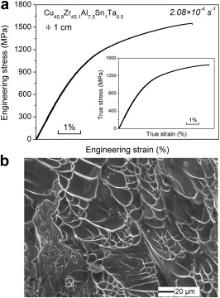

Mechanical properties of the large-sized Cu45.9Zr45.1Al7.5Sn1Ta0.5 sample are measured using the 1-cm-diameter rods with the aspect ratio of ∼1.5. Fig. 7(a) shows the room-temperature compressive stress-strain curves. Unlike the case of most monolithic BMGs, the composite specimen exhibits obvious work-hardening behavior before fracture and undergoes a pronounced plastic deformation of ∼4.6%. The yield strength σy and fracture strength σf of the alloy are determined to be ∼1020 MPa and ∼1550 MPa, respectively. The inset of Fig. 7(a) shows the true stress-strain curve of the alloy. The strain-hardening exponent n is a useful parameter reflecting the work-hardening ability of materials during deformation. Here, n is calculated to be ∼0.292 for this specimen. Fig. 7(b) shows the fracture morphology of the composite sample. It is seen that the sample exhibits extensive vein-like patterns on its fracture surface.

In summary, centimeter-scale CuZr-based BMGC with the composition of Cu45.9Zr45.1Al7.5Sn1Ta0.5 has been prepared successfully. The amount of Ta addition has a great influence on the types of the precipitated crystalline phases under the same casting conditions. The 0.5 at.% Ta addition can inhibit the precipitation of other crystalline phases rather than the CuZr(B2) phase during solidification. The present large-sized specimen shows excellent mechanical properties under room-temperature compression with visible plastic strain of ∼4.6% and obvious work-hardening behavior. The key point in fabricating large-sized CuZr-based BMGCs with good mechanical properties may be to prevent the precipitation of other crystalline phases such as the CuZr2 or Cu10Zr7, which may be harmful to their mechanical properties. This work may be helpful to defeat the size limitations of the BMGC and provide useful guidance for the development of large-sized CuZr-based BMGCs.

References

This work was financially supported by the National Natural Science Foundation of China (NSFC, Granted Nos. 51161130526 and 51101004). Z.Q. Liu acknowledges the support of the IMR SYNL-T.S. Kê Research Fellowship.

| 1. |

|

| 2. |

|

| 3. |

|

| 4. |

|

| 5. |

|

| 6. |

|

| 7. |

|

| 8. |

|

| 9. |

|

| 10. |

|

| 11. |

|

| 12. |

|

| 13. |

|

| 14. |

|

| 15. |

|

| 16. |

|

| 17. |

|

| 18. |

|

| 19. |

|

| 20. |

|

| 21. |

|

| 22. |

|

| 23. |

|

| 24. |

|

| 25. |

|

| 26. |

|

| 27. |

|