A composite composed of waste package poly(vinyl chloride) (WPVC) and organic montmorillonite (OMMT) was prepared by coextrusion, which is used for modifying asphalt. The micromorphology of the WPVC/OMMT composite and its effect on the macroscopic properties of asphalt were studied using a fluorescent microscope and an X-ray diffractometer (XRD). The introduction of OMMT allows the WPVC to be good dispersed in the asphalt matrix, as demonstrated by differential scanning calorimetry (DSC) and Fourier transform infrared spectroscopy (FTIR) analysis. The results indicate that asphalt modified by WPVC/OMMT composites with low OMMT content results in better high-temperature storage stability and physical properties of modified asphalt.

Asphalt has a complex chemical structure that varies with its origin and preparation method. When the asphalt is used in a roadway, its surface temperature can vary from below 0 ° C to more than 90 ° C in response to environmental conditions. To improve its pavement performance, asphalt is frequently modified using a variety of polymeric materials. A polymer-modified asphalt (PMA) and usually contains polymer contents ranging from 3% to 8%, by weight[1].

Numerous polymers, such as block styrene-butadiene-styrene copolymers (SBS), styrene butadiene rubber (SBR), and ethylene-vinyl acetate copolymers (EVA), are finding their way into polymer-modified asphalt pavements leading to enhanced performance[2]. To be useful, the modifying polymer must be sufficiently compatible with the asphalt and does not cause phase separation during storage at high-temperatures. In addition, combining a polymer with asphalt must not lead to a substantial increase in the viscosity of the asphalt in its molten state, to ensure that existing road-building processes and apparatus can still be applied. Moreover, economic and environmental benefits should also be considered, specifically, the polymer should be inexpensive and not pose an environmental risk[3].

Poly(vinyl chloride) (PVC) is the world's third most utilized polymer, ranking just behind polyethylene (PE) and polyethylene terephthalate (PET), which can be processed into a wide variety of packaging products and used in food production, cleaning materials, textiles, beverage bottles, and medical devices. Yet, in recent years, the question of the disposal of PVC waste has gained increasing importance, resulting from the rapid growth of PVC wastes[4]. In our previous research[5], waste packaging polyethylene (WPE) was used as a polymer modifier to lower the cost of modified asphalt and provide an effective method for recycling PE waste.

Nanomaterials have a large specific surface area and high surface free energy. The interfacial atoms are disordered, which facilitates the process of dispersing these materials in a matrix. Organic montmorillonite (OMMT) is one of such nanomaterials, but when it is used in high content as an asphalt modifier, it is difficult to be dispersed homogeneously due to its poor compatibility which can be attributed to the high viscosity of asphalt and the high surface energy of nano material[5] and [6]. Therefore in this study, OMMT by different content was added into WPVC to prepare a WPVC/OMMT composite, which was then employed as a modifier for asphalt, in hope of improving dispersion of OMMT in the asphalt.

| Table 1 Properties of original materials |

a Data are provided by Zhejiang Fenghong New Material Co., Ltd. (China). b Physical properties were conducted in accordance with ASTM D5, D36 and D113, respectively.

In this work, the preparation and properties of WPVC/OMMT composite were studied and the properties of asphalt that was modified using this composite were determined. For comparison, a controlled asphalt modified using only PVC was also examined. In addition, the compatibility of asphalt modified using the WPVC/OMMT composite was investigated and the effect of OMMT content on the high-temperature storage stability and physical properties of modified asphalt were discussed.

WPVC was obtained from recycled commercial blister packaging consisting primarily of PVC. Nanosized OMMT was supplied by Zhejiang Fenghong New Material Co., Ltd. (China). The base asphalt 90A# was obtained from China Petroleum and Chemical Co., Ltd. Xi'an Branch. Properties of these materials are summarized in Table 1[7]. Table 1 Properties of original materials

WPVC/OMMT nanocomposites were prepared using an SHJ-35 co-rotating twin-screw extruder (Nanjing, China). The mixing ratios of the samples are listed in Table 2. Barrel temperatures of the extruder from feeding section to discharge port were 160 ° C, 165 ° C, 170 ° C, 170 ° C, 165 ° C, 165 ° C, 160 ° C, 160 ° C and 150 ° C, respectively, and the speed of screw was 90 r/min. The resultant asphalt-modifying agent is shown in Fig. 1.

| Table 2 Component of the composites |

All of the modified asphalts were prepared using an FLUKO FM300 high shear emulsifier (Shanghai, China) at 150 ° C at a shearing speed of 3750 r/min for 1 h. Following this mixing procedure the binders were kept at about 120 ° C for 30 min to ensure full swelling of the modified agent, resulting in the experimental modified asphalts (as listed in Table 3). Prior to shearing with the emulsifier, the asphalt was heated in a small container until it flowed, and then the individual modifiers (WPVC/OMMT or WPVC) were added to each hot asphalt. The WPVC content of the final composite was 6 wt%.

| Table 3 Modified asphalt samples |

2.4.1. Thermal properties test

Differential scanning calorimetry (DSC) was used to observe the thermal characters of WPVC/OMMT composites. DSC analysis was conducted using a DSC 823e differential scanning calorimeter (Mettler Toledo, Switzerland) at a scan rate of 10 ° C/min, from 50 ° C to 230 ° C under argon.

2.4.2. XRD analysis

XRD analysis of the samples was conducted using an XRD-7000 diffractometer (Shimadzu, Japan), with a wave-length of 0.154056 nm (λ ), a step size of 0.1° and 2θ angle from 2° to 10° .

2.5.1. Physical properties and high-temperature storage stability test

Physical properties including penetration (25 ° C), softening point and ductility (5 ° C), were conducted in accordance with ASTM D36, D5 and D113, respectively.

Following preparation of the modified asphalts, some of the prepared modified asphalt was transferred into a glass tube (32 mm in diameter and 160 mm in height). The tube was sealed and stored vertically in an oven at 163 ° C for 48 h, and taken out, cooled to room temperature. After curing, a small hammer was used to gently break the tube into pieces and the glass fragments were cleaned. Then the samples were cut horizontally into three equal sections. The samples taken from the top and bottom sections were used to evaluate the storage stability of the modified asphalts by measuring their softening point difference.

2.5.2. FTIR analysis

Modified asphalt samples were coated onto a potassium bromide (KBr) disc. The infrared spectra were recorded with an FTIR-8400S spectrometer (Shimadzu, Japan).

2.5.3. Morphological analysis

A Nikon 80i fluorescent microscope (Japan) with an optical magnification of 200 was used to investigate the morphology of the modified asphalts by determining the dispersed state of the modifier in the base asphalt.

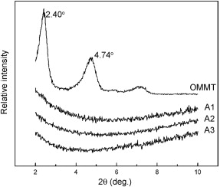

3.1.1. XRD analysis

The structure of the polymer/OMMT composites can be classified into two categories, intercalated and exfoliated, as determined by XRD analysis which exhibited the position and the intensity of diffraction peaks in XRD patterns[8]. The XRD curves of OMMT and WPVC/OMMT composite are shown in Fig. 2. The diffraction peaks of OMMT are positioned at 2θ = 2.40° and 4.74° (d001-reflection). From this result, the interlayer spacing of OMMT was calculated to be 3.7 nm and 1.9 nm by the Bragg formula (2dsin θ = λ ). For the composites, there is no obvious d001-reflection peak in the XRD curves, indicating that the interlayer spacing of OMMT in the composite is more than 4.4 nm (calculated by the Bragg formula, where 2θ = 2.00° and λ = 0.154056 nm) at least. According to our previous studies [5], we concluded that OMMT has peeled off in the process of preparation, forming exfoliated or partially exfoliated structure. The formation of an exfoliated structure increases the specific surface area of OMMT, facilitating the insertion of the asphalt and PVC molecules into OMMT structure.

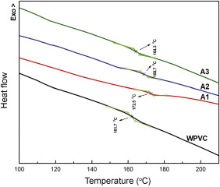

3.1.2. DSC

DSC reveals the thermal behavior of materials as a result of heat absorption and release. Fig. 3 gives the DSC curves of WPVC/OMMT composite, showing that no strong absorption or exothermic peaks are present. However, the variation of the heat flow in the samples shows deviation as revealed by the differences in the four curves. As shown in the figure, the variation in the slope of DSC curves of samples WPVC, A1, A2 and A3, is reversed at 161.7 ° C, 172.5 ° C, 168.7 ° C and 164.3 ° C, respectively. It means that the thermal behavior of them changes at a certain corresponding temperature (referred to as Tco). As seen in Table 1, the melting temperature range of PVC is between 160 ° C and 190 ° C, suggesting that aggregation state of PVC changes at Tco. It is believed that this phenomenon results from the PVC transformation from a high elastic state to a viscous flow state. Since PVC is an amorphous polymer, its macromolecular chain movement is enhanced at the Tco temperature. In addition, a dehydrochlorination reaction occurs when the WPVC is heated, which generates free radicals chains as shown in Fig. 4. The existence of a free radical on macromolecular chain and the exfoliated or partially exfoliated OMMT lamella will hamper the thermal motion of the molecular chain so that no endothermic peak is observed in the DSC curve [9] and [10].

In addition, the Tco values of A1, A2 and A3 composites are all higher than that of the WPVC sample. This is due to the large surface area of the exfoliated OMMT lamella allows it to more easily absorb the PVC molecular chain, thereby increasing the binding capacity of each. As a result, the WPVC/OMMT composite can maintain the consistency of its aggregated state at higher temperatures thereby exhibiting good heat resistance [11]. It is seen that, the Tco value decreases while the content of OMMT in the composite increases. This is due to the fact that the OMMT layers agglomerate in the composite as their content increases, hampering the exertion of nanoeffect. As a result, a declining tendency of the high-temperature stability of the WPVC/OMMT composite is observed, which results in a decrease in the Tco value.

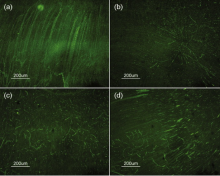

3.2.1. Morphology

The morphology and dispersion of the polymer in asphalt can be discerned using fluorescence microscopy. Fluorescence micrographs of modified asphalt are shown in Fig. 5. As is shown in these micrographs, the morphology of PVC in the asphalt matrix in the asphalt modified by WPVC/OMMT composite (2#, 3# and 4#) is different from the one modified by PVC (1#). The morphology of PVC in asphalt 1# is a long stripe shape, while in 2#, 3# or 4#, it is a branched network structure accompanied by some dispersed materials with a granulated shape.

It is concluded that the existence of exfoliated structure of OMMT results in numerous polar branches on PVC molecular chain inserted among the OMMT lamella. This is caused by the polarity of free radical chains and the large surface energy of OMMT. Therefore, the activity of PVC molecular chain increases, leading to the movement of the chain. Eventually the PVC is dispersed into the asphalt matrix where it formed the branched network structures enhancing the surface combination of PVC and asphalt. Meanwhile some PVC particles absorbed the lighter fractions of asphalt then swelled into the matrix, presenting the granulated shapes of various sizes, particularly in modified asphalt 3# and 4#. Though no network structure was formed, the compatibility of PVC and asphalt was enhanced as a result of swelling[12]. PVC was dispersed into the asphalt matrix by these two methods thereby improving the compatibility of PVC and asphalt.

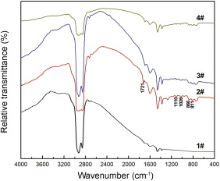

3.2.2. FTIR analysis

FTIR spectroscopy is a very versatile technique and is used frequently in analytical chemistry to provide information about chemical functional groups in complex solids[13] and [14]. FTIR spectra of the modified asphalt are shown in Fig. 6. The stretching vibration of C

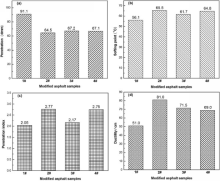

3.2.3. Physical properties

The effects on the physical properties of asphalt after the addition of WPVC and WPVC/OMMT composites are shown in Fig. 7. Penetration is a representation of a material's consistency reflecting the rheological properties and viscosity of asphalt at the testing temperature. In general, penetration of the modified asphalt decreases and its viscosity increases with the increase in the quantity of the polymer modifier. As seen in Fig. 7(a) and Table 1, the penetration of the modified asphalt generally decreased with the exception of sample 1# indicating that the modification effect of the WPVC/OMMT composites is superior. Therefore, OMMT improves asphalt pavement construction due to lower viscosity and increased resistance to cracking.

| Fig. 7 Physical indexes of modified asphalts: (a) penetration at 25 ° C; (b) softening point; (c) penetration index, PI; (d) ductility at 5 ° C |

Softening point defines the plastic flow of asphalt and reflects the high-temperature stability of the material. Generally, a high softening point means that the asphalt has high-temperature stability. As can be seen in Fig. 7(b) and Table 1, the softening point of modified asphalts all increased in comparison to base asphalt. In comparison to asphalt 1#, the softening point of 2#, 3# and 4# increased, indicating that the OMMT modification improved the high-temperature stability of these modified asphalts.

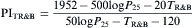

In this study, penetration index (PI), which reflects the temperature susceptibility of asphalt is calculated using the data for softening point and penetration in Table 1, Fig. 7(a) and (b) by the following equation[18] and [19]:

where P25 is the penetration of asphalt tested at 25 ° C, and TR& B is its softening point. The results of these calculations are shown in Fig. 7(c). As a temperature sensitive material, asphalt exhibits diverse properties at different road service temperatures. The larger the value of PI, the less sensitive the asphalt is to temperature change. The PI value of base asphalt was found to be -3.81, showing that the varying temperatures have a serious influence on material's properties. The increased PI value after modification means that the temperature susceptibility of modified asphalt is less than the base material, which helps to minimize materials' properties over a wide temperature range.

Ductility represents the extension or elongating of asphalt before the material will fracture under tension. Asphalt pavement has good durability with high ductility of asphalt. Low temperature ductility (at 5 ° C) is used internationally to characterize the anti-cracking performance of asphalt. In this study, the low temperature ductility of 90A# is more than 200 cm, indicating that the base asphalt has an excellent extension property. The ductility decreases when the asphalt is modified with WPVC; modified asphalt sample 1# is an example (Fig. 7(d)). However the ductility of asphalt modified by WPVC/OMMT composite (samples 2#, 3# and 4#) increases, compared to PVC modified asphalt (sample 1#), indicating an improvement of low temperature performance of pavement.

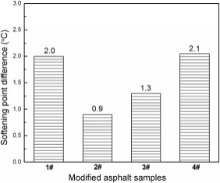

3.2.4. High-temperature storage stability

The softening point difference values of samples which can be determined from the high-temperature storage stability test are used to evaluate the storage stability of modified asphalt. A low value of softening point difference indicates better high-temperature storage stability of asphalt. Softening point difference values of modified asphalt are shown in Fig. 8. As can be seen, the softening point difference value of asphalts modified by WPVC or WPVC/OMMT composite is all very low, indicating that no obvious phase separation occurred

during high-temperature storage test. Therefore, the compatibility of asphalt and polymer (PVC) is excellent, revealing good modification effect combined with physical properties above.

hen the OMMT content is low, the softening point difference value of WPVC/OMMT modified asphalt (samples 2# and 3#) is less than the one of WPVC modified asphalt (sample 1#) indicating that asphalt modified by composite with low OMMT content has better high-temperature storage stability. It can be concluded that both the swelling of the PVC in the asphalt matrix and the intercalation of the PVC and asphalt molecules into the OMMT lamella, results in an asphalt-polymer interphase which further improves the compatibility of these diverse materials[20].

However, with a higher content of OMMT, the relevant modified asphalt (sample 4#) exhibits no materials' advantage over WPVC modified asphalt, meaning that the addition of OMMT doesn't improve the compatibility of PVC and asphalt to an anticipated degree. This indicates that a higher content of OMMT in asphalt matrix appeared to force the OMMT particles to agglomerate, which went against the intercalation of the PVC and asphalt molecules into the OMMT. Therefore, the enhancement of compatibility is mainly based on the swelling of PVC in asphalt matrix. As a result, no obvious difference is observed between asphalt samples 1# and 4#.

XRD analysis shows that the WPVC/OMMT composite forms a type of nanocomposite material with an exfoliated structure. Compared to WPVC, the high-temperature stability of the composite is improved resulting from the addition of OMMT, but it decreases with the increased content of OMMT. The exfoliated structure of OMMT in WPVC/OMMT composites and the swelling of WPVC both promoted further dispersion of the PVC in the asphalt, enhancing the compatibility of the PVC and the asphalt appropriately, thereby improving both high and low temperature performance of modified asphalt. It is concluded that the WPVC/OMMT modified asphalt in which the modifying composite contains a high OMMT content offers no advantage over modified asphalt containing only WPVC, because of agglomeration of the excess OMMT. As a result, when too much OMMT is employed in the composite, its ameliorating properties are swamped by other factors.

The authors have declared that no competing interests exist.

| [1] |

|

| [2] |

|

| [3] |

|

| [4] |

|

| [5] |

|

| [6] |

|

| [7] |

|

| [8] |

|

| [9] |

|

| [10] |

|

| [11] |

|

| [12] |

|

| [13] |

|

| [14] |

|

| [15] |

|

| [16] |

|

| [17] |

|

| [18] |

|

| [19] |

|

| [20] |

|