Effect of Hot Isostatic Pressing Conditions and Cooling Rate on Microstructure and Properties of Ti-6Al-4V Alloy from Atomized Powder

Effect of Hot Isostatic Pressing Conditions and Cooling Rate on Microstructure and Properties of Ti-6Al-4V Alloy from Atomized Powder |

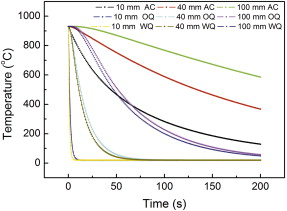

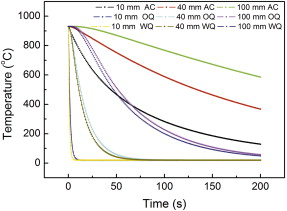

| Fig. 6 Simulation prediction of temperature field distribution with different cooling routes. The geometry locations change from 5 to 60 mm, radial distance from the edge of samples |

|