Effect of Hot Isostatic Pressing Conditions and Cooling Rate on Microstructure and Properties of Ti-6Al-4V Alloy from Atomized Powder

Effect of Hot Isostatic Pressing Conditions and Cooling Rate on Microstructure and Properties of Ti-6Al-4V Alloy from Atomized Powder |

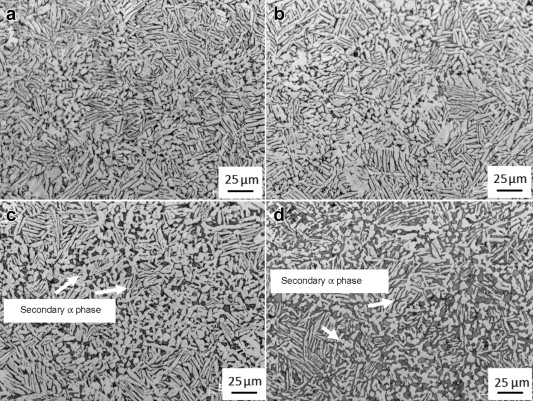

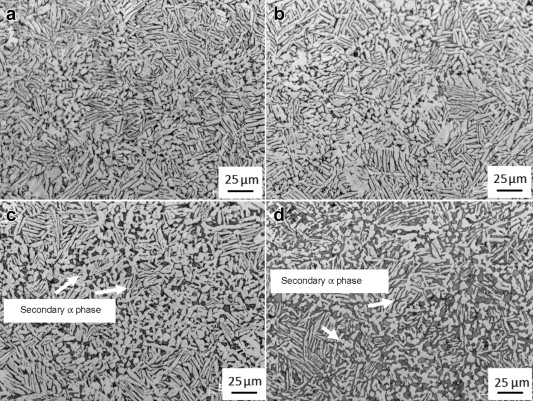

| Fig. 9 Optical micrographs of the Ti-6Al-4V specimens: a cutting from position 1 for AC, b cutting from position 3 for AC, c cutting from position 1 for WQ, and d cutting from position 3 for WQ. AC: air cooling; WQ: water quenching Heat treatment such as water quenching or oil quenching followed by aging treatment can obtain finer microstructure, however these microstructures contain metastable #cod#x003b2; phase. Therefore, for PM parts with complex structure, proper cooling route should be used to ensure the homogeneous microstructure and the best combination properties. |

|