In this study, plasma nitriding was carried out on pure titanium film coated 2024 Al alloy to improve its surface mechanical property. Ti film with the thickness of 3.0 μm was firstly fabricated by means of magnetron sputtering method. Then, the Ti coated specimen was subjected to plasma atmosphere comprising 40% N2-60% H2 at 430 °C for 8 h. The microstructures of the nitrided specimens were characterized by X-ray diffraction and scanning electron microscopy. Microhardness tester and pin-on-disc tribometer were used to test the mechanical properties of the untreated and nitrided specimen. The results showed that the surface of the nitrided specimen was composed of three layers (i.e. the outside nitride TiN0.3 layer, the middle Al3Ti layer and the inside Al18Ti2Mg3 layer). The surface hardness and wear resistance of 2024 Al alloy were increased simultaneously by duplex treatment. The untreated specimen exhibited severe adhesive wear while the nitrided one behaved in middle abrasive wear.

Aluminum alloys have numerous industrial applications due to their attractive properties such as light weight, high specific strength and favorable mechanical formability[1]. However, the widely spread use of these materials has been limited by their low hardness, poor wear resistance and high pitting corrosion tendency. Various methods such as physical chemical deposition, plasma electrolytic oxidation, plasma spray, plasma nitriding, ion implantation and laser surface alloying are employed to improve the surface properties of Al alloy[2], [3], [4], [5], [6], [7] and [8]. However, the methods mentioned above usually yielded single kinds of coatings like ceramics or intermetallics. Recently, surface composites coatings containing ceramics and intermetallics have gained increasing attention due to their improved surface mechanical properties[9], [10], [11], [12] and [13].

Duplex surface treatment was an effective method to obtain these composite coatings. Liu et al.[14] employed laser nitriding on Al coated Ti6Al4V alloy substrate to produce in situ formed TiN/Ti3Al coatings (IMC). The increment of microhardness, elastic modulus and the decrement of fracture toughness of coatings was obtained with decreasing the laser scanning speeds. Sun et al. [15] applied low-temperature plasma nitriding on the SMAT (surface mechanical attrition treatment) Ti/Al clad sheet to produce a nanostructured surface layer composed of ε -TiN and γ -Ti2N. The effect of plasma nitriding on the Ni-Al composite coatings developed by electro-deposition process was investigated by Daemi et al. [16]. Nitriding treatments were also employed on Ni-B coating to obtain enhanced mechanical properties [17] and [18]. A novel hard composite coating (Ni matrix with dispersions of nanosized CrN particles) was fabricated by plasma nitriding of Ni-Cr nanocomposite film [19]. The hard particles in above composite coatings were mainly introduced by plasma nitriding, neglecting the adhesive strength between coatings and the substrate. However, surface alloying with transition elements (e.g., Ti, Ni, Fe, Nb) and ceramic particles might be another effective choice to produce composite coatings, leading to the improved surface properties of Al alloy as well as an enhanced adhesive strength by metallurgical bonding. Uenishi and Kobayashi [20] employed laser cladding to produce Al3Ti-ceramic (TiC, TiB2 and SiC) composite layers on the surface of aluminum alloy, resulting in the improvement of wear property.

Titanium played an important role in surface alloying Al alloy as well as the formation of nitrogen-rich solid solutions and nitrogen containing compounds. Thus, the aim of this paper was to develop a novel method, through which duplex coating or composite coating comprising titanium based nitrides and intermetallics can be in situ synthesized. The method can be divided into two steps, namely depositing pure Ti coating on 2024 Al alloy substrate by magnetron sputtering, and plasma nitriding Ti coating in a mixture atmosphere made of nitrogen and hydrogen. The microstructure and wear property of duplex coatings were also investigated.

The nominal chemical composition of 2024 Al alloy used in this study is given in Table 1. The duplex coating was prepared on 2024 Al alloy substrate with two procedures (deposition/nitriding). The process of depositing Ti film was conducted by a closed field unbalanced magnetron sputtering ion plating system (Teer, UDP450/4) with high quality Ti target (99.999%). The base pressure of the chamber is 4 × 10-3 Pa. Prior to the deposition, substrates were etched by Ar plasma sputtering at a bias of -400 V for 40 min. A bias of -70 V was employed on substrates and the power of Ti target was switched to 1.8 kW for depositing process holding for 4 h. Plasma nitriding (PN) was performed in a nitriding unit (LDMC-30, 30 kW). The chamber was evacuated to below 5 Pa by a rotary pump and then heated up to 430 ° C by plasma atmosphere generated by a gas mixture (40% N2-60% H2). The nitriding process was held at a constant pressure of 226 Pa for 8 h. Then, the specimens were cooled down in a nitrogen gas flow.

| Table 1 Chemical composition of 2024 Al alloy (wt%) |

The phase structures of the surface duplex coating were analyzed by X-ray diffraction (type, Philips X’ Pert diffractometer) using CuKα radiation (λ = 0.15406 nm). A scanning electron microscope (SEM, FEI QUANTI 200F) equipped with energy dispersive X-ray spectrometer (EDS) was used to evaluate the surface and cross-sectional morphologies and chemical composition analysis of the surface duplex coatings. The surface hardness of untreated and coated specimen was measured using a Vickers microhardness tester (HV-1000) at the indentation load 10 g for 15 s. Pin-on-disk wear tests were used to examine wear resistance of the coated and uncoated 2024 Al alloy specimens with a normal load of 2 N, under dry sliding condition at room temperature and ambient humidity. During wear tests, the cylindrical pins (20 mm in diameter and 5 mm in height) of the 2024 Al alloy (before and after plasma nitriding) were rotated against a stationary hardened chromium steel (HRC 64) ball of 5 mm in diameter at a speed of 200 r/min (0.1 m/s) for 1200 s. The tested specimens were weighted by an electronic balance with accuracy up to 0.1 mg before and after the wear test to calculate mass loss. The specific wear rate (WN) was calculated by the expression: WN = Δ M/(L × n), where Δ M (g) is the weight loss, L (N) is the contact load and n (r) is the total number of turns. The worn surfaces and wear debris of tested specimens were characterized by scanning electron microscopy (SEM).

The XRD patterns of Ti coated 2024 Al alloy before and after plasma nitriding are illustrated in Fig. 1. As can be seen from Fig. 1(a), Ti film with hexagonal structure was obtained by magnetron sputtering method, which was consistent with previous studies[21] and [22]. Obviously, nitride (identified as TiN0.3, JSCPDS No. 41-1352) was formed on the surface of Ti coated Al alloy after plasma nitriding. According to Ti-N phase diagram[23], nitrogen-rich solid solutions and compounds containing low nitrogen could occur below 700 ° C while TiN and Ti2N usually form at higher temperature. In the present study, with low nitriding temperature (430 ° C), conventional nitrides were difficult to form. TiN0.3 crystallized in a hexagonal structure with the space group P63/mmc, which was similar to that of α -Ti. Thus, the compound TiN0.3 could be identified as α -Ti (N) solution. As can be seen from Fig. 1(b), intermetallic phase Al18Ti2Mg3 and Al3Ti were also formed in the modified layer of Al alloy.

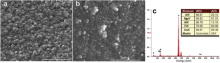

The surface morphologies of Ti coated Al alloy before and after plasma nitriding are illustrated in Fig. 2. It can be seen from Fig. 2(a), a dense Ti film with facet microstructure was successfully deposited on the surface of 2024 Al alloy. The size of the Ti particles was in the range of about 250 nm. After plasma nitriding, Ti particles changed to much finer particles with the size of 50 nm, resulting in much more dense coating on the surface of 2024 Al alloy (Fig. 2(b)). Some particles grew into clusters with the size of about 450 nm. In order to understand the composition change of Ti film after plasma nitriding, the EDS analysis was carried out. Fig. 2(c) shows the EDS spectra on the surface of nitrided specimen. The presence of high nitrogen content indicated that Ti film was successfully nitrided. The nitrided particles were identified as TiN0.3 by previous XRD analysis.

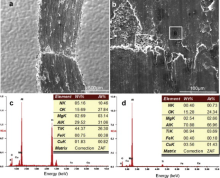

| Fig. 2 SEM images showing surface morphologies of Ti coated specimen: (a) before PN treatment, (b) after PN treatment at 430 ° C for 8 h, (c) EDS spectra on the surface of nitrided specimen |

In order to understand the changes that occurred between the Ti film and 2024 Al alloy substrate, the cross-section microstructure observation was conducted. Fig. 3(a) gives the cross-section morphologies of Ti coated 2024 Al alloy before and after plasma nitriding. The deposited Ti film was uniform with thickness of about 3.33 μ m. No interface reaction was observed during the deposition process. After plasma nitriding, three layers with distinct interface between each other formed on the surface of 2024 Al alloy (Fig. 3(b)). The corresponding elements depth profiles across the transverse section of the modified layer displayed in Fig. 3(c) show that two kinds of reaction occurred during plasma nitriding Ti coated 2024 Al alloy, i.e. (a) reaction between N atoms and Ti film to produce nitrides; (b) reaction diffusion between Ti film and 2024 Al alloy substrate to produce intermetallic layer. According to the XRD results and elements depth profiles, the duplex coatings comprising three sublayers identified as the outmost TiN0.3 layer in white color, the middle Al3Ti layer and the inside Al18Ti2Mg3 layer. The approximate thickness of the three sublayers was 1.5, 1.1 and 5.5 μ m, respectively. Thus, the duplex coating with total thickness of about 8.1 μ m was successfully fabricated on the surface of 2024 Al alloy.

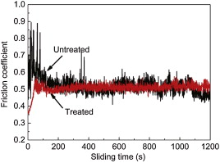

The dry sliding wear behaviors of the untreated and plasma nitrided specimen were evaluated by using a ball-on-disc tribometer. As can be seen from Fig. 4, the wear rate of the plasma treated specimen has a significant decrease as compared to the untreated one. As is known to all, the wear resistance was related to the surface hardness of materials. Materials with higher hardness usually exhibited better wear resistance. The surface hardness of the plasma nitrided specimen is more than 450 HV0.01, which is about five times harder than that of the untreated one. Thus, the nitrided specimen was expected to possess better wear resistance.

The friction coefficients vs sliding time curves of the plasma nitrided and untreated specimens are shown in Fig. 5. The stable friction coefficients of the tested specimens were found to be similar (0.52 for the untreated one, 0.5 for the nitrided one). However, the sliding curves of the untreated samples exhibited larger fluctuation than the nitrided one. This large fluctuation in the sliding curves resulted from the lower surface hardness of the substrate.

| Fig. 5 Frictional coefficient curves of the untreated and the nitrided specimens with a GCr15 ball under 2 N. |

Fig. 6 shows the SEM micrographs of the worn surfaces of the untreated 2024 Al alloy generated through testing at a normal load 2 N. The wear track of the untreated sample was illustrated in the pattern of grooves and rides extending parallel to each other in the sliding direction (Fig. 6(a)). The grooves and ridges were caused by plastic deformation and micro-ploughing of the soft alloy by the hard steel counterface, accompanied by the removal of material[24]. Material smearing and dark colored compact surface layers were also visible in the wear track. EDS analysis was carried out to understand the changes that occurred on the sliding surface of the untreated Al alloy during wear. As can be seen from the EDS spectrum in Fig. 6(c), the dark colored area (marked by A) contained a high content of oxygen, indicating the occurrence of oxidation reaction. The oxidation caused by the local high temperature due to compact contact between the hard steel counterface and the soft Al alloy. The EDS spectrum in Fig. 6(d) revealed that the chemical composition of area B was close to that of the 2024 Al alloy. It can be concluded that the wear mechanism of the 2024 Al alloy under the present test condition exhibited the typical characteristic of adhesive wear, which was in accordance to the extensive reports for soft and ductile materials such as copper and gold[25].

| Fig. 6 SEM images showing worn surface morphologies of the untreated specimen: (a) low magnification, (b) high magnification, (c) EDS spectrum of the area A, (d) EDS spectrum of the area B |

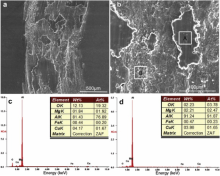

Fig. 7 shows the SEM micrographs of the worn surfaces of the nitrided 2024 Al alloy. Obviously, the wear track width for the nitrided specimen (Fig. 7(a)) was much narrower than that of the untreated one. The ploughed grooves inside the wear tracks and formation of wear debris were evidence of abrasive wear caused by the hard particles ploughing into the pin. A significant decrease of craters, finer grooves, less smearing were observed on the worn surface of the nitrided specimens (Fig. 7(a)), resulting in less material removing from the tested surface. As can be seen from the high magnification micrograph of the wear track of the nitrided sample (Fig. 7(b)), fine wear debris dispersed in the craters (area A) and cracks were also visible. The EDS spectrum in Fig. 7(c) revealed that the wear debris in area A contained large amounts of nitrogen and titanium. These debrises came from the spalling of the outside nitride layer (TiN0.3). The hard nitride particles acted as abrasive medium, resulting in the ploughing grooves. The EDS spectrum in Fig. 7(d) showed that oxidation occurred in area B. Moreover, the large amount of Al in area B indicated that the modified layer was worn through under the present test condition.

| Fig. 7 SEM images showing worn surface morphologies of the nitrided specimen: (a) low magnification, (b) high magnification, (c) EDS spectrum of the area A, (d) EDS spectrum of the area B |

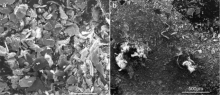

The wear debris of the untreated specimen displayed metallic shining with white color while the nitrided one exhibited black color, which was readily identifiable during the test by the naked eye. Fig. 8 gives the wear debris morphologies for the tested specimens. Obviously, the wear debris of the nitrided specimen has a much smaller size than that of the untreated one, in agreement with the wear rate in Fig. 4. The wear debrises of the untreated specimen were large flake-like particles (about 200 μ m, in Fig. 8(a)). The stratified morphology of the wear debris was the evidence of an adhesion mechanism for the untreated alloy, which is in agreement with previous studies[26] and [27]. Two types of debris morphology for the nitrided specimen were observed in Fig. 8(b), i.e. the fine particles of 1.5-4.0 μ m in diameter and large particles with a plate-like morphology (about 50-180 μ m in diameter). The distinct shape and size of wear debris of the test specimens originated from their different hardness. Since the soft Al alloy has good plastic deformation ability, it was inclined to machine by hard steel counterface. While the hexagonal compound TiN0.3 and intermetallics (Al3Ti and Al18Ti2Mg3) exhibited higher hardness and brittle tendency. Cracks could occur in the outside hard layer enduring cyclic load during wear test. As a consequence, the fine nitride particles (Fig. 2) peeled from the surface layer to form abrasive particles.

(1)A novel duplex coating was fabricated on the surface of 2024 Al alloy by plasma nitriding.

(2)Under the experimental conditions, plasma nitriding of deposited Ti film resulted in the formation of TiN0.3, Al3Ti and Al18Ti2Mg3, which increased the surface microhardness of Al alloy.

(3) The results of the dry sliding tests indicated that the stable friction coefficients of the untreated and nitrided specimens were similar. The improvement of the surface hardness led to the decrease of the fluctuations of friction curves for the nitrided specimen.

(4)The wear rate of the nitrided specimens decreased remarkably compared with that of the untreated one. The wear mechanism for the nitrided specimen was a mixture of abrasive wear and slight adhesive wear.

The authors gratefully acknowledge the Specialized Research Fund for the Doctoral Program of Higher Education of China (Grant No. 20112302130006) for the financial support of this work.

The authors have declared that no competing interests exist.

| [1] |

|

| [2] |

|

| [3] |

|

| [4] |

|

| [5] |

|

| [6] |

|

| [7] |

|

| [8] |

|

| [9] |

|

| [10] |

|

| [11] |

|

| [12] |

|

| [13] |

|

| [14] |

|

| [15] |

|

| [16] |

|

| [17] |

|

| [18] |

|

| [19] |

|

| [20] |

|

| [21] |

|

| [22] |

|

| [23] |

|

| [24] |

|

| [25] |

|

| [26] |

|

| [27] |

|