By using electron backscatter diffraction (EBSD) and transmission electron microscopy (TEM), the effect of Si content on microstructure characteristics of three as-extruded Al-Si-Mg alloys was investigated. Results showed that the density of coarse Si particles played a critical role in dynamic recrystallization. Dynamic recrystallization rarely occurred in S1 alloy with less Si content; however, it happened in the Si-rich zones in S2 alloy with a medium Si content. And a mature recrystallization was observed in S3 alloy with high Si content. Although deformation was carried out at high temperature, particle-stimulated dynamic recrystallization occurred in Si-rich zones.

In recent years, many researchers have focused their interests on the microstructure and mechanical properties of Al-Si base alloys with high content of Si[1], [2], [3] and [4]. Studies confirmed that hot deformation resulted in a good combination of tensile strength and ductility in Al-Si alloys[5]. Among these reports, researchers paid more attention on the improvement of mechanical properties while the evolution of microstructure and strengthening mechanisms are rarely discussed. Though dynamic recrystallization would be mentioned occasionally, such as the studies reported by Ding et al.[5] and Wang et al.[6], few systematic studies have been carried out on the recrystallization mechanism of Al-Si alloys, let alone of alloys containing a large number of Si particles. Particle stimulated nucleation (PSN) of dynamic recrystallization has been frequently reported in magnesium matrix composites[7], [8] and [9], in copper containing Al2O3, SiO2 and GeO2 particles[10] and [11], and in aluminum alloys containing hard, second phase particles (> 1 μ m) during static recrystallization[12], [13] and [14]. But it has only been observed in aluminum matrix composite (Al-Mg (5083)/SiCp and Al-Mg (5083)/Al2O3p) when extruded at high temperature and with high extrusion ratios[15] and [16]. Recently, Ramesh et al.[17] reported that PSN is the dominant mechanism for the recrystallization in Al 6061 composite with nickel-coated SiCp when extruded at 843 K, which was confirmed by the low value of Zener-Hollomon (∼1012 s-1). However, they did not observe the phenomenon directly.

Due to a large number of non-deformable Si particles in the matrix, it is difficult to characterize the as-deformed microstructure evolution of Al-Si alloys through traditional analysis techniques. Transmission electron microscopy (TEM) and scanning electron microscopy (SEM) are usually used to characterize the detailed microstructure of heavily deformed alloys[18] and [19]. Grain boundary characteristics are the key to understand the physical process of dynamic recrystallization, which can be obtained much more reliably and quantitatively by electron backscatter diffraction (EBSD)[20], [21] and [22]. Therefore, the objective of the current work is to characterize the microstructure of as-extruded near eutectic Al-Si-Mg alloys by EBSD and TEM to obtain a direct information of the role of Si particles in dynamic recrystallization.

Three Al-Si-Mg alloys, nearly single-phase Al-0.6 wt% Si-0.5 wt% Mg (S1 alloy), hypoeutectic Al-7 wt% Si-0.5 wt% Mg (S2 alloy) and nearly eutectic Al-12.3 wt% Si-0.5 wt% Mg (S3 alloy) were melted and cast into an iron mold with an inner cavity of 60 mm in diameter. The chemical composition of the studied alloys is given in Table 1 (measured by an ARL-3460 spectrum). The cylinder castings were homogenized at 535 ° C for 6 h, then immediately hot extruded into 35 mm × 5 mm sheets. The sheets were quenched directly by water at the die exit. Previous study has proved that the quenching method can retain the dynamic microstructure effectively[23]. EBSD samples were machined from the as-extruded sheets. First, they were cut into pieces of 1-2 mm in thickness (from the ED-ND plane), then ground with metallographic abrasive paper from 600 to 2000 mesh and polished with diamond paste of 2.5 μ m in particle size. All samples were electropolished in a 5% perchloric acid alcohol solution at -25 ° C and 30 V for 30 s (for S1 alloy), and at -10 ° C and 20 V for 10 s (for alloys S2 and S3). For EBSD investigation, an scanning electron microscope equipped with a field emission gun was used at an operation voltage of 25 kV. The map step size of 0.3 μ m was used. The EBSD maps were obtained by using TSL-EDAX OIM analysis software. And texture measurements were presented in the form of orientation distribution functions (ODF). The ODFs were calculated from 0° to 90° for φ 1, Φ and φ 2.

| Table 1 Chemical composition of the studied alloys (wt%) |

Fig. 1 shows the optical microstructures of the three alloys in as-cast (a-c) and as-homogenized (d-f) conditions (the insets in upper right corner of (b, c, e, f) are the locally amplified micrographs). There are a number of second phases distributed in S1 alloy in as-cast condition (as shown in Fig. 1(a)), which are Mg2Si and π -Fe phases. However, after being homogenized, the alloy almost exhibits single phase with a small number of β -Fe phase, as shown in Fig. 1(d). S2 alloy is composed of α -Al dendrites and eutectic, and the eutectic Si phases are fibrous, as shown in Fig. 1(b). After homogenization, the dendrites are not so obvious and the fibrous Si turns into spherical particles, as can be seen in Fig. 1(e). The microstructure of S3 alloy is similar to that of S2 alloy; however, it has a larger number of eutectic and a smaller number of dendrites, as given in Fig. 1(c, f). Several studies[24], [25] and [26] have demonstrated that the final average grain size and the mechanical properties of alloys are insensitive or independent to initial grain size during hot deformation, so the present paper mainly discusses the effect of Si content on the microstructure evolution of Al-Si alloys during hot extrusion.

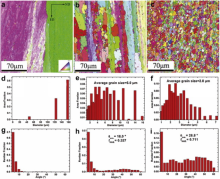

The microstructure characteristics of the three alloys after hot extrusion are shown in Fig. 2. In EBSD maps (Fig. 2(a-c)), low-angle boundaries (LABs) (misorientation between adjacent grains of 2° -15° ) and high-angle boundaries (HABs) (misorientation larger than 15° ) are shown with gray and black lines, respectively. Due to the wide banding structure, a few grains can be obtained in the observed EBSD maps of S1 alloy (Fig. 2(a)), then the statistics is poor (Fig. 2(d)). However, it still can clearly be distinguished from the other two alloys. The average grain size of as-extruded S1 alloy exceeds 100 μ m. Fig. 2(g) demonstrates that most grain boundaries in it are of low angles, namely sub-grain boundaries. This indicates that almost no recrystallization occurs during extrusion. In S2 alloy, the Si content is 7 wt% and there are many Si particles in the as-cast eutectic zones. After extrusion, it is found that recrystallization has developed in specific zones (the as-cast eutectic zones) of this alloy, as shown in Fig. 2(b). Though there is still considerable part of banding structure in it, the bands are much narrower than that in S1 alloy, and the average grain size of S2 alloy is greatly decreased to about 6.0 μ m, as shown in Fig. 2(b, e). The number fraction of LABs in it reduces remarkably compared to the S1 alloy, meanwhile, the number fraction of HABs rises up to about 33%, as shown in Fig. 2(h). Therefore, it can be inferred that recrystallization has partially occurred during extrusion of S2 alloy. Fig. 2(c) reveals the microstructure characteristics of as-extruded S3 alloy. The banding texture has never been seen, with numerous, very fine equiaxed grains instead. Undoubtedly, these are maturely recrystallized grains, with an average grain size of about 2.8 μ m (Fig. 2(f)). Fig. 2(i) reveals that the number fraction of LABs decreases further compared with that in S2 alloy, and more than 70% grain boundaries are HABs. Thus, in S3 alloy with a great number of non-deformable Si particles, recrystallization has maturely developed during hot extrusion.

Fig. 3 reveals the relationship between grain or sub-grain boundaries with silicon particles (Si particles are marked with blue, and matrix with red). S1 alloy contains 0.6 wt% Si and 0.5 wt% Mg, which is almost single phase in as-homogenized condition (as visualized in Fig. 1(d)). As shown in Fig. 3(a), no visible second-phase particles are observed and only a few HABs from elongation of the original grain boundaries are seen, however, there are a great number of sub-grains (LABs) arranging in a regular banded array. S2 alloy contains 7 wt% Si and 0.5 wt% Mg, where more than 50% eutectic is expected according to Al-Si-Mg ternary phase diagram. After homogenization, eutectic Si particles are spheroidized (as can be seen in Fig. 1(e)). And the as-cast eutectic zones are elongated into Si-rich bands during hot extrusion, as shown in Fig. 3(b). Intriguingly, recrystallizing operates more likely in the silicon-rich bands, not in the Si-poor bands. At the same time, more sub-grain boundaries are seen in the Si-poor bands than in the silicon-rich bands. Fig. 3(c) demonstrates the effect of Si particle density more clearly. S3 alloy contains 12.3 wt% Si, near the eutectic point of Al-Si binary phase diagram. A few α -Al dendrites are formed in castings. After homogenization, eutectic Si particles distribute in the α -Al matrix more uniformly (as visualized in Fig. 1(f)). During hot extrusion, Al matrix has recrystallized maturely, and the grains are much finer than that of S2 alloy, as shown in Fig. 3(c). Fig. 3(d, e) are the locally amplified details of Fig. 3(b, c), respectively, which visualize clearly that the grain and sub-grain boundaries correlate closely with the spacing of Si particles (i.e., relate to the content of Si in the alloy under the same extrusion processing).

| Fig. 3 Phase distribution of S1 alloy (a); S2 alloy (b, d); S3 alloy (c, e); (d) and (e) are the local amplification of (b) and (c), respectively. |

In order to understand the differences among the three alloys more thoroughly, further texture analysis was carried out. Fig. 4 is the orientation distribution functions (ODF) of the three as-extruded alloys. Compared to the relative position of important orientation on commonly used space orientation section of the cubic crystal system[27], S1 alloy exhibits strong deformation textures with copper and brass components, the intensities of which are more than 70 and 40, respectively. Besides, there is very weak Goss component in S1 alloy, which is a kind of recrystallization texture, as can be seen in Fig. 4(a). Therefore, almost no recrystallization occurs in S1 alloy. Textures in S2 alloy are rather complicated and the intensities are much lower than that in S1 alloy, as shown in Fig. 4(b). There are two kinds of recrystallization textures, which are Cube and R components, and also two kinds of deformation textures, which are Brass and S components. The intensities are all around 20, indicating that partial recrystallization has occurred in S2 alloy, which is in accordance with the results in Fig. 2 and Fig. 3. The texture in S3 alloy is the simplest, only containing Cube recrystallization component. In other words, full recrystallization has occurred in S3 alloy. From above observations, it is rational to conclude that Si particles play a critical role in inducing the recrystallizing operation of Al matrix in Al-Si-Mg alloys during hot extrusion.

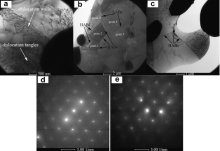

Fig. 5shows the typical microstructures of as-extruded S2 alloy observed by TEM. Dislocation tangles and dislocation walls can be observed in the sample, and the dislocation density exhibits a gradient which is denser when closer to the Si particles, as shown in Fig. 5(a). Fig. 5(b) shows the distribution characteristic of LABs and HABs, which is closely related to the distance from Si particles. In the region close to Si particles, there is obvious contrast between grain 1, grain 2 and the surrounding grains, and the grain boundaries are very clear to be seen. It is believed that these boundaries have transformed into HABs during deformation. In the region relatively far away from Si particles, the selected area electron diffraction (SAED) of grain 3 and grain 4 shows a single net pattern (as shown in Fig. 5), which indicates that the two grains scarcely have misorientation. Therefore, the boundary between grain 3 and grain 4 is LAB. The SAED of grain 4 and grain 5 exhibits a similar phenomenon that there is almost no deviation of the orientations between the two grains (as shown in Fig. 5(e)), which means the boundary between grain 4 and grain 5 is also LAB. Fig. 5(c) provides another example that the grain boundaries close to the Si particles are more likely to transform into HABs during hot extrusion.

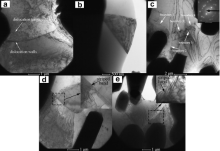

Fig. 6 shows the typical microstructures of as-extruded S3 alloy observed by TEM. Dislocation tangles and dislocation walls can be observed near the Si particles, as can be seen in Fig. 6(a). Recrystallization nuclei are found adjacent to Si particles, as shown in Fig. 6(b). The most typical microstructure found in S3 alloy is HAB. As shown in Fig. 6(c), boundaries 1, 2 and 3 form a typical trigeminal interface such as the situation in Fig. 5(c), so the three boundaries are all HABs. The inserted SAED pattern of the trigeminal interface composed of boundary 3, 4 and 5 is much more diffused than that in Fig. 5(d, e), indicating that these three boundaries have transformed into HABs. Besides, striped bands are frequently observed in the sample, which are HABs resulting from grain boundary sliding, as shown in Fig. 6(d, e). The results demonstrate that recrystallization occurs more frequently and readily near Si particles especially in Si-rich zones and particle stimulated dynamic recrystallization occurs during hot extrusion.

Dislocation generating and removing occur together during hot deformation. If there is no enough net dislocation accumulation, no recrystallization will occur. Regions near particles are with high dislocation density and large orientation gradient, named as particle deformation zones (PDZs). The PSN mechanism is well understood in situations that a particle-containing material is deformed at a low homologous temperature and then annealed at a higher temperature to induce recrystallization[20], [21] and [28]. In such circumstances recrystallization nuclei are formed in the deformation zones surrounding particles on the order of 1 μ m in size and these nuclei then grow during annealing. Humphreys and Kalu[29] modeled the critical conditions for PSN of two-phase aluminum alloys at elevated temperatures, depending on the temperature, strain rate and particle size. By calculating the transition condition, they concluded that particle stimulated dynamic recrystallization is the most unlikely. It is in accordance with the results obtained from the Si-poor zones of S2 alloy, as there are not enough dislocations accumulated. However, the model only considers dislocation accumulation around a sole particle, not taking the particle spacing into account. The volume fraction of Si particles in S3 alloy is more than 14% and the particle spacing is very small (as shown in Fig. 3(c, e)). Although deformation was carried out at high temperature, the climb rate of dislocations would be greatly restricted by the close distribution of large Si particles. Therefore, the arriving rate of dislocations around the Si particles is much greater than their removing rate, and then dislocations will accumulate around the particles as geometrically necessary dislocations[30] immediately when deformation begins. With deformation proceeding, the edges of dislocation cells will rearrange and polygonize and form nuclei. The cell walls of nuclei will be flatted into sub-grains with the help of high temperature and grow up. Finally, full recrystallization occurs in the Si-rich alloy under the common action of strain and temperature. So, it is observed that recrystallized grains are more likely to be formed in the Si-rich zones of both S2 and S3 alloys. It is similar to some cases that coarse dispersoid/inclusion particles may lead to more inhomogeneous deformation[31] and [32] and hence encourage faster accumulation of dislocations and more rapid appearance of high angle grain boundaries during severe deformation[31] and [32]. In S1 alloy, though deformed in the same extrusion processing, the removing rate of dislocations is faster than that of S2 and S3 alloys, so there is no enough dislocation accumulation and the driving force is not sufficient for dynamic recrystallization. Therefore, almost no dynamic recrystallization occurs in S1 alloy and the main texture of S1 alloy is deformation texture. Recrystallization maturely occurs in the Si-rich zones of S2 alloy and rarely occurs in the Si-poor zones. So there are both recrystallization texture and deformation texture in S2 alloy. In the sample of S3 alloy, full recrystallization occurs as Si particles distribute uniformly and closely in the matrix. So the main texture in S3 alloy is recrystallization texture. Above all, different contents of Si lead to different deformation textures and recrystallization texture in S1, S2 and S3 alloys subjected to identical deformation.

(1)High density of Si particles induced dynamic recrystallization of Al matrix in Al-Si-Mg alloys during hot extrusion.

(2)Dynamic recrystallization rarely occurred in S1 alloy with a few Si particles; however, it happened in the Si-rich zones in S2 alloy with a medium Si content. And a mature recrystallization was observed in S3 alloy with high Si content, resulting in a remarkable grain refinement.

(3)Although deformation was performed at high temperature, particle stimulated dynamic recrystallization occurred in Si-rich zones.

The authors thank Prof. Fan Li, Prof. Haibo Huang and Prof. Aiqun Xu for the valuable discussion of EBSD test and TEM analysis, respectively. This work was financially supported by the Jiangsu Graduated-student Innovation Program of China (CXZZ-0146) and the Scientific Research Foundation of Graduate School of Southeast University (YBJJ1235).

The authors have declared that no competing interests exist.

| [1] |

|

| [2] |

|

| [3] |

|

| [4] |

|

| [5] |

|

| [6] |

|

| [7] |

|

| [8] |

|

| [9] |

|

| [10] |

|

| [11] |

|

| [12] |

|

| [13] |

|

| [14] |

|

| [15] |

|

| [16] |

|

| [17] |

|

| [18] |

|

| [19] |

|

| [20] |

|

| [21] |

|

| [22] |

|

| [23] |

|

| [24] |

|

| [25] |

|

| [26] |

|

| [27] |

|

| [28] |

|

| [29] |

|

| [30] |

|

| [31] |

|

| [32] |

|