A water-quenching technique has been adopted to evaluate thermal shock fracture and fatigue behaviors of porous Si3N4 ceramics in an air atmosphere. The high-porosity Si3N4 ceramics exhibit a higher strength retention and a better resistance to thermal shock fatigue because of its role of the pores as crack arresters. A dense and coherent surface oxide layer leads to a significant benefit in residual strength during thermal fatigue, however, an increased fatigue number to 30th cycle cannot cause a further influence although a thicker oxide layer presents, which is attributed to holes defect and disappearance of part intergranular phase.

The perfect combination of microstructures and mechanical behaviors is expected because it provides a mechanism for designing materials used under harsh conditions and for improving their performance. Over the past few decades, porous Si3N4 ceramics as functional components have been extensively employed in various industrial fields such as catalyst supports, antenna windows, radiant burners, hot insulators, and filters for hot gases due to their excellent dielectric properties, good oxidation resistance, high bending strength at room and elevated temperature, and remarkable thermal shock resistance[1], [2], [3], [4] and [5]. In the majority of applications, porous Si3N4 ceramics often encounter strong heat flow and/or abrupt temperature shock, which can lead to instantaneous thermal stresses and subsequently make ceramics become sensitive to crack or harm. The thermal shock behavior of porous ceramics in service has been widely researched and developed on many occasions[6], [7] and [8], and it is well established that the residual strength after thermal shock was discovered to decrease gradually or interruptedly over a critical thermal shock temperature difference and the thermal shock resistance was observed to increase with increasing porosity, independent of whether the shape of pore in matrix is fully regular or ordered. The conclusions have been verified in a variety of experiments for single-phase porous ceramics accompanying the efforts of researchers[9] and [10].

| Fig. 1 SEM images of porous Si3N4 ceramics with the porosities of 32% (a), 37% (b), and 42% (c).1218 X. Lu et al.: J. Mater. Sci. Technol., 2014, 30(12), 1217e1222 |

Apart from this, the investigations of thermal shock behavior of Si3N4 composite ceramics also have been conducted with some remarkable progresses. For instance, the critical temperature difference of 30 wt% BAS/Si3N4 is over 1100 ° C and the retained strength at a quenching-temperature difference of 1100 ° C is hardly affected by the quenching cycles[11]. The highest critical temperature difference was obtained from 15 wt% TiN/Si3N4 nano-composite, and the addition of TiN particles can also improve the resistance to thermal shock damage[12]. Porous BN-SiO2-Si3N4 composites were successfully obtained with good critical thermal shock temperature of 800 ° C[13].

In general, the thermal-shock experiments are performed by means of measuring the residual flexural strength in an air atmosphere after quenching heated specimens from successively higher temperatures into a water bath. Before quenching, the samples are first kept at expected high temperatures for some time in order to eliminate any temperature gradient within them and achieve thermal equilibrium prior to quenching, which may give rise to some oxidation on porous Si3N4 ceramic surface. It has been reported that such an oxidation can improve the ability of materials to endure external forces by sealing surface flaws[14], [15] and [16], and follow by the increase of mechanical strength. This reveals that the measured strength after thermal shock should embody the comprehensive influences of surface oxidation and thermal shock on materials performance.

However, while increased thermal shock resistance by way of increasing porosity has often been reported, only a few studies have examined the positive effect of surface oxidation on residual strength of porous Si3N4 ceramics preceded by thermal shock, especially for multiple cycles of thermal shock. Thus, understanding such influence mechanism is critical for reliability and optimization of a wide range of porous Si3N4 ceramics. In view of the above description, in this paper, the porous Si3N4 ceramics with porosities of 32%-42% were obtained through die-pressed under different pressures and gelcasting followed by gas-pressure sintering, and then were used to evaluate the thermal shock behavior with emphasis on the influence of surface oxidation on mechanical property. Our goal is twofold. One of the objectives is to investigate how the porosity affects both the crack initiation related to thermal shock fracture resistance and crack propagation concerning thermal shock damage resistance. Another objective is to determine the influence of oxide layer on the residual flexural strength of porous Si3N4 ceramics after multiple cycles of thermal shock with the aim of collecting some information on the thermal shock applications of porous Si3N4 ceramics.

The initial raw materials employed in the present work were Si3N4 powders (average particle size: 0.37 μ m, α phase > 95 wt%). Al2O3 (1 μ m, 99% purity, 1 wt%) and Y2O3 (5 μ m, 99.9% purity, 2 wt%) were used as the sintering additives. A mixture of α -Si3N4, Al2O3 and Y2O3 was ball-milled in alcohol for 24 h. After being dried and sieved through a 100-mesh screen, the resultant powder mixture was die-pressed at 35.7 and 10.7 MPa and then pressure-sintered for low and middle porosity Si3N4, respectively, or by gelcasting and subsequently gas-pressure sintering for high-porosity Si3N4. In all cases, sintering was conducted at 1800-1900 ° C for 4 h with a heating rate of 10 ° C/min under a nitrogen pressure of 0.4 MPa, utilizing Si3N4 powders as protecting particles to inhibit the decomposition and deformation. Testing specimens with dimensions of 3 mm × 4 mm × 40 mm were obtained through diamond cutting and ground mechanically with the tensile surface perpendicular to the axis direction. Flexural strength of samples was determined by three-point bending tests at room temperature with a span of 16 mm and a crosshead speed of 0.5 mm/min. The porosity of samples was determined by means of Archimedes displacement method, employing distilled water. Fracture toughness was measured by the single-edge notch beam (SENB) technique with a notch span of 3 mm and a height of 2.3 mm at a loading rate of 0.1 mm/min by precracking. The linear coefficient of thermal expansion was calculated from thermal expansion that measured by dilatometer up to 1000 ° C at a heating rate of 5 ° C/min in vacuum. Young's modulus and Poisson's ratio were determined by the uniaxial compression and pulse-echo methods, respectively. Table 1 lists the physical and mechanical properties of the investigated porous ceramics. Fracture surfaces of the samples were observed by scanning electron microscopy (SEM, Model JSM-7000F, JEOL, Japan). As shown in Fig. 1, fine elongated rod-like grains with the length of 10 μ m and diameter of 1 μ m are randomly oriented and jointed to form pores.

| Table 1 Relevant physical and mechanical properties of porous samples after sintering |

hermal shock resistance experiments were performed by quenching the specimens (3 mm × 4 mm × 40 mm) from a resistance furnace into 20 ° C water bath. The specimens were heated in air at a rate of 10 ° C/min to a preset temperature and held at this temperature for about 20 min prior to quenching. The specimens were dropped parallel to their long axes into the water. Then, the residual flexural strength of the quenched specimens was measured under the same conditions as those of unquenched specimens. The strength results of specimens in this work are given as the average values of three measurements. The critical thermal shock temperature difference can be determined by ASTM standard C1525-04 to be the temperature at which 70% of the room temperature strength was still retained. Thermal shock damage resistance experiments were conducted by repeating the heating and quenching procedure, and the assessment of which can be realized via comparing the extent of damage of porous specimens after repeated thermal shock experiments.

| Fig. 1 SEM images of porous Si3N4 ceramics with the porosities of 32% (a), 37% (b), and 42% (c). |

Considerable efforts about thermal shock behaviors of porous Si3N4 ceramics have been devoted. In general, several thermal shock resistance parameters (R parameters) have been employed to assess the thermal shock resistance of materials. The residual strength of ceramics after thermal shock remains unchanged until the temperature difference (Δ T) achieves a critical value (Δ Tc), where crack initiates. When Δ T > Δ Tc, crack propagates severely or quasi-statically, followed by a sudden or gradual drop in strength. Thus, two parameters of R and R′ ′ ′ ′ can be employed to reflect the resistance of a ceramic to thermal-shock crack initiation and propagation, respectively, and be different from the resistance in fracture mechanics.

The residual strength of material is of importance with regard to the thermal shock resistance and the critical temperature difference (Δ Tc) is a thermal shock resistance parameter representing the maximum allowable temperature difference to which a body can undergo without the initiation of fracture. Since the presence of the thermal stress when materials undergo rapid temperature shock is the primary reason for a decrease in the strength, the thermally generated stress (σ t) is interrelated with the temperature difference (Δ T) based on thermoelasticity theory by the following equation [17]:

equation(1)

where α is the coefficient of thermal expansion, v is Poisson's ratio, and E is Young's modulus. When the thermal stress (σ t) exceeds the fracture strength (σ f) of a ceramic, the damage and cracking may occur according to Eq. (1). Then, the Δ Tc for crack initiation by temperature shock may be evaluated from

equation(2)

According to this formula, it is expected that a ceramic with high strain-failure (σ f/E) and strength, low Poisson's ratio, low Young's modulus, and low thermal expansion coefficient will prevent thermal shock crack initiation. Simultaneously, the reliability of ceramics with lower E is higher than that of those ceramics with the similar α , v and Δ T according to Eq. (1). The R value captures the initiation of thermal shock cracking under thermal shock conditions and higher values of R are in favor of greater resistance to fracture initiation during quenching.

The thermal shock damage parameter R′ ′ ′ ′ can be expressed by the following equation [18]:

equation(3)

where σ f is the flexural strength, and KIC is the fracture toughness. The parameter R′ ′ ′ ′ represents the resistance to catastrophic crack propagation of ceramics, and embodies the maximum extension of possibly pre-existing cracks before failure. The value of R′ ′ ′ ′ increases as the fracture toughness and Poisson's ratio increase and strength decreases. The calculated R and R′ ′ ′ ′ values are calculated by using the experimental data and listed in Table 1. It can been seen that the R value drops with increasing porosity, implying that low-porosity Si3N4 ceramics would exhibit a high resistance to crack initiation compared to high-porosity Si3N4 ceramics. On the contrary, the calculated R′ ′ ′ ′ values increase as porosity increases, indicating that high-porosity Si3N4 ceramics would display a high resistance against crack propagation. In general, when a porous ceramic is subjected to thermal shock, crack is likely to occur at the pores on the surface, where the thermal stress is the maximum. For a given thermal shock severity, a relatively large number of cracks may initiate and propagate in high-porosity ceramics, leading to a decrease of crack initiation resistance ability (i.e. low R value). However, when a crack reaches a pore, the crack may be forced to alter its path or even stop at the pore. Thus, the cracks can propagate only over a relatively short distance and then become arrested by the pores, resulting in an increase of crack propagation resistance in high porous ceramics (i.e. high R′ ′ ′ ′ value).

3.1.1. Thermal shock fracture

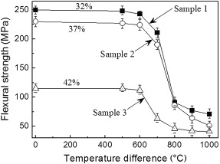

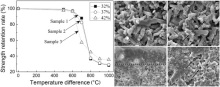

Fig. 2 and Fig. 3 show the flexural strength and strength retention rate, respectively, as a function of quenching-temperature difference for porous Si3N4 ceramics with porosities of 32% (sample 1), 37% (sample 2), and 42% (sample 3). As can be seen from Fig. 2, the flexural strength of the samples 1 and 2 degrades abruptly above 700 ° C, so the critical temperature differences of thermal shock are above 700 ° C, while it is lower than 700 ° C for the sample 3 because of the fact that the strength has begun to decline sharply above 600 ° C. The result coincides with the change trend of parameter R in Table 1. Nevertheless, it is worth noting that the differences between R and observed Δ Tc values in Fig. 2 are particularly evident, because of the dramatic reduction in heat-transfer coefficient after the formation of protective steam bubbles at the water/specimen interface. This would mitigate the severity of thermal shock and result in overestimated Δ Tc values, compared to the expected R parameter [19], [20] and [21]. In addition to this, the small sample size employed in study may be another factor responsible for higher Δ Tc value than R[22]. It can also be observed in Fig. 3 that the strength retention rates for the samples 1 and 2 after thermal shock Δ T of 700 ° C remained about 85% relative to their primary strength, while about 57% for the sample 3. However, the strength retention rate exceeding Δ T of 700 ° C shows an abrupt decrease for the samples 1 and 2 but a gradual reduction for the sample 3. The retained strength for the sample 3 after thermal shock at Δ T of 800 ° C maintains about 45 MPa, while the retained strength decreases to about 37 MPa for the samples 1 and 2. The degree of strength retention is the highest for the sample 3 in accordance with the change of the calculated R′ ′ ′ ′ values in Table 1 similar to that reported by the literature [7]. The finding should be associated with more connected open pores by high porosity, which can promote the reduction of stress concentration and possess good crack propagation resistance. The presence of these stages demonstrates the feature of the Hasselman's model for the thermal shock [23]. Fig. 4(a-f) illustrates the typical morphologies of fracture surface of thermally shocked samples. In Fig. 4(c) and (f), some agglomeration of glass phase as indicated by the arrows can be observed, leading to the decrease in residual strength for the sample 3, while there is almost no change in morphologies for the samples 1 and 2 after thermal shock at Δ T of 700 ° C as shown in Fig. 4(a) and (b), preserving retained strength invariably. The agglomeration of glass phase may be attributed to the interaction of heat flux and water vapor, resulting in the degraded bonding between the grains and possibly being the initiation of the crack. Meanwhile, the reunion can also be seen in Fig. 4(d) and (e) after thermal shock at Δ T = 800 ° C, causing weak interfacial bonding forces among grains and thus the sharp reduction in residual strength for the samples 1 and 2. The trend is consistent with the change of residual strength in Fig. 2. Comparing to the intergranular fracture at room temperature before quenching, the transgranular fracture after thermal shock possibly appears similar to that of dense ceramics in temperature shock test. The above description indicates that low-porosity Si3N4 may exhibit a high capability of the resistance to crack initiation while a low capability of the resistance towards crack propagation. Therefore, Si3N4 with low porosity may be suitable for a relatively mild thermal shock environment. In contrast, a low capability of the resistance to crack initiation, but a high capability of the resistance to crack propagation may be expected for high-porosity Si3N4, which is applicable for severe thermal shock circumstance where crack cannot be avoided.

Crack initiation, propagation and ultimate fracture make up the whole processes of thermal fatigue behavior of ceramic materials. Therefore, the fracture initiation and crack propagation resistance become two main design parameters used to express thermal shock resistance. After cracks appear, the resistance of crack propagation is very important. In the case of thermal shock, the driving force for crack propagation comes from the elastic energy stored in the body caused by thermal stress. When the elastic energy is larger than crack surface energy, the excess energy would transform into kinetic energy, and then crack propagation occurs and stops until the elastic deformation energy reaches equilibrium with the crack surface energy. When the body with inherent flaws is subjected to severe thermal shock, damage may emerge at peaks of those pre-existing flaws weakening the strength.

Fig. 5 and Fig. 6 show the residual strength and strength retention rate, respectively, at a quenching-temperature difference of 600 ° C for porous Si3N4 ceramics subjected to repeated thermal shock. It can be seen in Fig. 6 that the degree of the strength retention under thermal cycling increases through the sequence of ceramics with porosities of 32%, 37%, and 42%. This ascension is mainly associated with fracture toughness and flexural strength and consistent with the calculated R′ ′ ′ ′ . Owing to a relatively high value of KIC/σ f, the sample 3 exhibits less strength degradation after thermal cycling, and the strength retention rate of which decreases only by about 70% up to 20th cycle. It indicates that the maximum number of thermal shock damage resistance is larger than 20 and the propagation state of crack is stable and the crack growth rate in thermal cycles is low. Simultaneously, the strength retention rates of the samples 1 and 2 rapidly drop to below 50% up to 10th cycles, implying that the maximum number of cycles are lower than 10. This trend is associated with pores acting as a stress concentrator in ceramics matrix. In the case of thermal shock, crack is probable to emerge on the surface because of larger thermal stress. When suffering the same thermal shock severity, a relatively larger number of cracks may initiate and propagate in porous ceramics, while the more pores can limit the extension of each crack, leading to a decrease in crack depth and consequently in strength loss. Moreover, the pores can also take on the role of crack arresters. As a crack encounters a pore, the crack may be constrained to alter its path or even stop at the pore. In high-porosity ceramics, the cracks can propagate only over a relatively short distance and then become arrested by the pores [7], and thus crack propagation occurs in a quasi-static manner and the strength undergoes a gradual decrease. Thus, the high-porosity ceramics have the best capability to thermal fatigue resistance. In order to improve the thermal shock resistance of porous Si3N4 ceramics, it is of importance to design the materials with specific microstructure for the purpose of getting an optimal state between the resistance to crack initiation (R) and crack propagation (R′ ′ ′ ′ ).

| Fig. 5 Residual flexural strength as a function of the number of thermal shock cycles at Δ T = 600 ° C. |

The surface oxide layer of the specimens before quenching also undertakes a major role in the improvement of thermal shock resistance. In order to further investigate the effect of oxide layer on thermal shock behavior, the fracture surface and specimen surface for ceramics with a porosity of 32% with different number of thermal shock cycles at Δ T = 600 ° C were observed in Fig. 7. The oxide layer of sample may act as an additional thermal barrier, which could weaken the effective cooling rate at the interface and, consequently, the intensity of thermal shock affects the stress state at the surface. Related reports have well concluded that surface oxidation of non-oxide ceramics could improve the thermal shock resistance because of the healing cracks and generation of surface compressive stresses [24] and [25]. It can be seen from Fig. 7(a1-c1) that the thickness of oxide layer is about 5 μ m up to 10th cycle and increases to 20 μ m up to 30th cycle, and the surface is covered completely by a dense and coherent oxide layer, similar to that reported by the references [11] and [26], resulting in a significant increase in strength. The presence of such an oxide layer might act as an additional thermal barrier, which could weaken the heat-transfer rate by convection and thus leading to a reduction in the intensity of thermal shock. However, combined with Fig. 7(b2), one can see that the surface of sample would produce some holes defect as the arrows point to after 20th cycle, and these fields can form fracture source when subjected to external force by the exposed surface of sample causing weak connections between the surface and body. With the number of thermal shock cycles increasing, the intergranular phase as shown by arrows in Fig. 7(c2) would disappear clearly due to the interaction of heat flow and water vapor, leading to weak bonding between the grains and possibly followed by the drop of residual flexural strength although with increasing film thickness. Consequently, the beneficial effects of oxide layer is apparent in the range of some thermal shock cycles, that is 10 times in the present study, and subsequently reduces slightly as the number of cycles increasing owing to holes defect and disappearance of part intergranular phase. Thus, the measured residual strength decreases gradually due to the combination influences of the positive effect by oxide layer and slight negative effect by the disappearance of part intergranular phase.

It can be deduced from the above analysis that for some practical insights in the selection of porous ceramics concerning thermal shock applications, low-porosity ceramics should be adopted to avoid crack initiation when served in a relatively mild condition, while high-porosity ceramics are preferred to prevent the catastrophic crack propagation when severe thermal environments are involved. On the other hand, a dense and coherent surface oxide layer leads to a significant benefit in residual strength by healing surface crack and acting as an additional thermal barrier during thermal fatigue. Therefore, some preoxidation microstructure of Si3N4 components before exposure to a thermal shock environment is recommended in practical engineering. In summary, high porosity is a key influencing factor for thermal shock resistance and porous ceramics with well pore-size distribution and high open porosity have been widely used because of their predominant properties. Therefore, it is desirable to arrange microstructure and pore-size distribution ideally for the purpose of balancing mechanical strength and thermal shock resistance of materials.

A water-quenching technique was used to evaluate the thermal shock and fatigue behavior of porous Si3N4 ceramics with a variety of porosities in an air. The principal conclusions can be summarized as follows:

(1)In thermal shock fracture experiment, the critical temperature difference related to crack initiation is above 700 ° C for the samples 1 and 2, while lower than 700 ° C for sample 3, indicating that low-porosity Si3N4 may exhibit a high capability of the resistance to crack initiation and be suitable for a relatively mild thermal shock environment.

(2)In thermal shock damage experiment, the strength retention concerning crack propagation increases in the sequence of ceramics with porosities of 32%, 37%, and 42%. It shows that the high-porosity Si3N4 ceramics exhibit a better resistance to thermal shock fatigue and a higher strength retention because of the role of the pores as crack arresters.

(3)The formation of a dense and coherent surface oxide layer has a significant benefit for residual strength during thermal fatigue and the beneficial effect is apparent in the range of some thermal shock cycles, that is 10 times in the present study, and slightly reduces with increasing the number of cycles owing to holes defect and disappearance of part intergranular phase. Some preoxidation microstructure of Si3N4 components is recommended in practical engineering when a thermal shock environment is involved.

The authors have declared that no competing interests exist.

| [1] |

|

| [2] |

|

| [3] |

|

| [4] |

|

| [5] |

|

| [6] |

|

| [7] |

|

| [8] |

|

| [9] |

|

| [10] |

|

| [11] |

|

| [12] |

|

| [13] |

|

| [14] |

|

| [15] |

|

| [16] |

|

| [17] |

|

| [18] |

|

| [19] |

|

| [20] |

|

| [21] |

|

| [22] |

|

| [23] |

|

| [24] |

|

| [25] |

|

| [26] |

|