Characteristics of Twin Lamellar Structure in Magnesium Alloy during Room Temperature Dynamic Plastic Deformation

Characteristics of Twin Lamellar Structure in Magnesium Alloy during Room Temperature Dynamic Plastic Deformation |

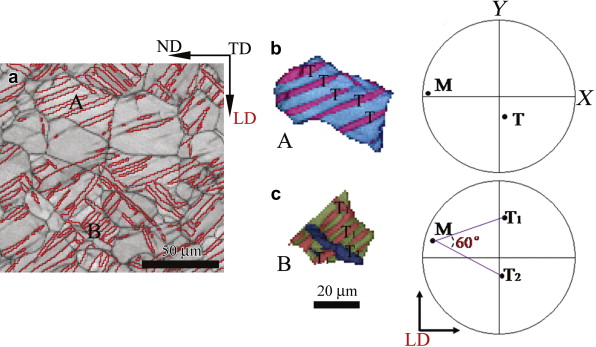

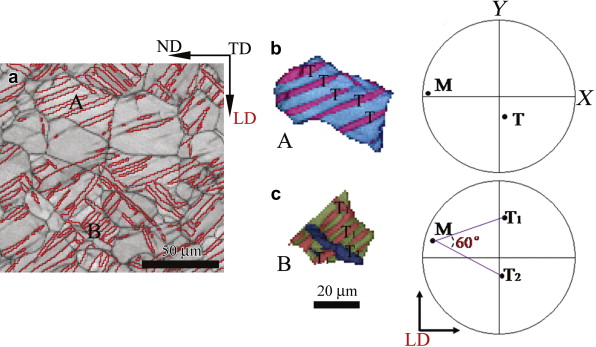

| Fig. 5. a Microstructure of DPD sample with ε = 4.3%, red lines indicate img height="23" width="59" alt="View the MathML source" title="View the MathML source" src=".Characteristics of Twin Lamellar Structure in Magnesium Alloy during Room Temperature Dynamic Plastic Deformation_filesgrey_pxl.gif" data-inlimgeid="1-s2.0-S1005030213001758-si1.gif" style="display: inline; " math altimg="si1.gif" overflow="scroll" mrow mrow mo { mo mrow mn 10 mn mrow mover accent="true" mn 1 mn mo stretchy="true" ¯ mo mover mrow mn 2 mn mrow mo } mo mrow mrow math twin boundaries; sketch maps b and c show grain A and B in a and their crystallographic orientations, respectively, M represents grain matrix, T, T1 and T2 represent activated img height="23" width="59" alt="View the MathML source" title="View the MathML source" src=".Characteristics of Twin Lamellar Structure in Magnesium Alloy during Room Temperature Dynamic Plastic Deformation_filesgrey_pxl.gif" data-inlimgeid="1-s2.0-S1005030213001758-si1.gif" style="display: inline; " math altimg="si1.gif" overflow="scroll" mrow mrow mo { mo mrow mn 10 mn mrow mover accent="true" mn 1 mn mo stretchy="true" ¯ mo mover mrow mn 2 mn mrow mo } mo mrow mrow math twin variants. |

|