Tubes of 3.5 vol.% TiB whiskers reinforced Ti6Al4V matrix composites (TiBw/Ti6Al4V) were successfully fabricated by a two-step hot-hydrostatic extrusion process: β extrusion at 1100 °C and subsequent near-β extrusion at 950 °C. The dimensions of tubes were about 7 mm in diameter and 2 mm in thickness. A refined basket-weave structure in Ti6Al4V matrix was achieved at ambient temperature after the extrusion process. Besides, the original network structure formed by TiB whiskers synthesized was broken, while the TiB whiskers were preferentially aligned in the extruding direction. Meanwhile, a fibrous texture was evolved finally, resulting from partial dynamic recrystallization during the β extrusion and the involvement of α phase during the near-β extrusion. The tensile and compressive tests results showed that both the strength and ductility of the tubes were significantly improved. In particular, the tubes exhibited good mechanical properties at elevated temperatures.

Cost-effective discontinuously reinforced titanium matrix composites (DRTMCs) are attractive materials for aerospace, automotive and military applications [1] and [2] owing to their high specific strength and high specific modulus, excellent corrosion resistance and high temperature durability. In practice, TiB whisker (TiBw) has the characteristics of high thermostability and high mechanical stability, and is considered as a suitable discontinuous reinforcement for titanium alloys [3], [4] and [5]. Additionally, Huang et al. [6]reported that TiBw/Ti6Al4V composites with novel network microstructure, which were fabricated through reactive hot pressing, exhibited better mechanical properties than that of DRTMCs with homogeneous microstructures [7] and [8]. Undoubtedly, network structured TiBw/Ti6Al4V composites are preferable material for tubes applied in hydraulic pipelines for aerospace, nuclear power and auto industries. However, there are few researches on the production technology of titanium matrix composites tubes. As for the preparations of titanium alloy tubes, extrusion and rolling were the most common methods [9] and [10]. The conventional production processes could be divided into two types: (1) productions of tube billet, including mechanical drilling, extrusion, skew rolling perforation and plate welding; (2) productions of finished tubes, including rolling, extrusion, drawing and spinning [11]. There is no doubt that higher strength and modulus would bring more difficulties to the deformation of titanium matrix composites (TMCs). Thus, higher requirement of tooling and plastic forming technology are required in producing TiBw/Ti6Al4V composite tubes. Taking the specific requirements and current production processes into consideration, hot-hydrostatic extrusion was selected in the present study due to its uniform deformation and significant decrease of extrusion pressure [12]. Furthermore, the effects of hot-hydrostatic extrusion deformation on microstructure and mechanical properties were also examined in detail.

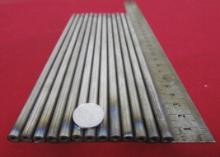

The 3.5 vol.% TiBw/Ti6Al4V composites selected as initial material were produced by hot-pressing sintering in a vacuum atmosphere (10-2Pa) at the temperature of 1200 °C for 1 h under a pressure of 20 MPa. The sintered composites were subjected to a hot-hydrostatic extrusion with an extrusion ratio of about 10.6 at 1100 °C (denoted as β extrusion) and transformed to the rods with a diameter of 16 mm. Then, the rods were machined into hollow specimens with the dimension of 6.5 mm in thickness, and further extruded at 950 °C (denoted as near-β extrusion) with an extrusion ratio of about 5 into the tubes. Finally, tubes with 7 mm in diameter and 2 mm in thickness were fabricated after further surface grinding (shown in Fig. 1). Both the extrusions were performed on a 4-column hydraulic press with a pressing velocity of about 10 mm/s.

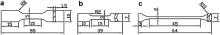

Metallographic observations of the specimens were performed on an OLYMPUS GX71 optical microscope (OM). The preparation consisted of careful mechanical grinding, polishing and subsequent etching using the Kroll's solution (5 vol.% HF + 10 vol.% HNO3+ 85 vol.% H2O) for 10 s. X-ray diffractions (XRD) were performed on an XD-2700 equipment along the extruding direction (ED) of specimens to identify the phases. Scanning electron microscopy (SEM) observation was carried out with a Hitachi S-570 scanning electron microscope equipped with energy dispersive spectroscopy (EDS) system. Electron backscattering diffraction (EBSD) was performed on a JEOL 733 electron probe equipped with a TSL OIM analysis system to identify the texture patterns as well as the prior β grains for specific specimens. The shapes and dimensions of tensile specimens along the ED for different conditions are shown in Fig. 2. The compressed specimens were cylindrical (for sintered composites) and tubular (for final tubes) with a ratio of height to external diameter of 1.5. Tensile and compressive tests were carried out on an Instron-5569 machine at ambient temperature (AT), and on an Instron-1186 machine at elevated temperatures. All the specimens were tested under a strain rate of about 1 × 10-3s-1, and a soaking time of 10 min at elevated temperatures (if necessary).

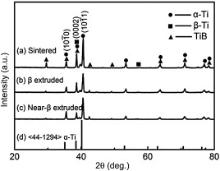

Fig. 3 displays the XRD patterns of the sintered and extruded 3.5 vol.% TiBw/Ti6Al4V composites compared with the standard XRD pattern of α titanium powder (PDF44-1294). As shown in the figure, TiB phase has been synthesized in the sintered composites and maintained during the process. Meanwhile, the intensity of some specific peaks of TiB changed apparently after extrusions, suggesting a preferred orientation generated for TiB. As for the matrix, the intensity of the peaks after the β extrusion was similar to that of the standard α titanium card, but comparatively a slight increase for the intensity of the

| Fig. 3. XRD patterns of the composites of the sintered (a), the β extruded (b), the near-β extruded (c) and standard α titanium powder (d). |

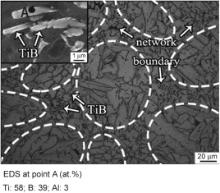

Fig. 4 shows the corresponding microstructure of the sintered TiBw/Ti6Al4V composites. It is clear that whisker-like (about 1.5 μm in width) phase enriched with B (as determined by EDS) formed a typical network structure around Ti6Al4V matrix particles after sintering [13]. Combined with the results of XRD, the composition of the whisker-like phase can be identified as TiB. The higher content of Ti was likely attributed to the contribution of the Ti6Al4V matrix, as supported by the existence of Al. The matrix structure was mainly composed of lamellar α grain with a thickness of about 10 μm and thin intergranular β phase with a thickness of less than 0.5 μm. It is noteworthy that the α phase close to TiBw in network boundaries has not been fully grown up, showing an obvious suppression effect of TiBw [14] and [15].

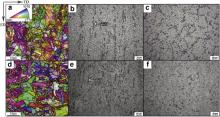

Fig. 5 shows the microstructures of the extruded composites in the longitudinal and transverse sections derived from EBSD and OM. Prior β grain boundaries were reconstructed using the misorientation criterion between α-colonies in the orientation maps from EBSD referring to the research of Gey and Humbert [16]. It can be seen that many large prior β grains with a grain size larger than 10 μm were elongated during extrusion. Fine equiaxed prior β grains with a grain size of about 3 μm were also observed around the elongated grains, showing a partial dynamic recrystallization during the β extrusion. Furthermore, fine α-colonies precipitated along the prior β grain boundaries and finally formed the basket-weave microstructure in ambient temperature. The average thickness of α grains in the refined Ti6Al4V matrix was about 2.3 μm, which is less than a quarter of the initial ( Fig. 4). Additionally, the initial network microstructure with TiBw has been gradually broken with the processing, and as anticipated, TiBw tended to align along the ED simultaneously, which was also suggested by the peak analysis in the XRD. After being subjected to the subsequent near-β extrusion, the Ti6Al4V matrix remained the fine basket-weave microstructure consisting of acicular α-colonies and intergranular β phase, but the grain boundary seemed to be clearer and straighter. Meanwhile, the TiBw became further disperse, which would be beneficial to the improvement of ductility.

The {0002},

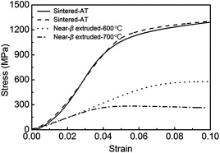

Fig. 7 provides the tensile stress–strain curves of the sintered and near-β extruded composites at different conditions. Similar yield strengths (0.2% proof stress) at ambient temperature for both conditions were about 910 MPa, but a remarkable increase in strength for the final tubes was observed subsequently, leading to an ultimate tensile strength of about 1155 MPa (about 10% higher than that for the sintered composites). Cai et al. [19] reported a similar increase in strength in Ti6Al4V alloy after a hot-hydrostatic extrusion above about 1150 °C, and mainly attributed it to the grain refinement of the lamellar structure, especially perpendicular to the extruding direction. Considering the above-discussed microstructures, it can be concluded that the current enhancement of strength may be regarded as being composed of the three additive parts: grain refinement strengthening, TiBw reinforcing and fibrous texture strengthening. It can be noted that the current extrusions tended to produce a fairly weak texture compared to the strong (0001) fibrous texture at 600–700 °C, referring to the research of Zherebtsov et al. [20], and naturally led to a weak contribution of texture to the strengthening. Meanwhile, the corresponding elongation was significantly enhanced from 6.5% to 14.7%, largely because of the refined matrix structure and the dispersed and aligned TiBw. In the research of Gungor et al. [21], Ti6Al4V tubes with ultimate tensile strength of 960 MPa, yield strength of 857 MPa and elongation of about 13% had been fabricated via a similar β extrusion. Comparatively, the TiBw/Ti6Al4V composite tubes fabricated by the current process exhibit a better performance in both strength and ductility.

| Fig. 7. Tensile stress–strain curves of the sintered and near-β extruded composites at different conditions. |

High-temperature resistance is another advantage for TiBw/Ti6Al4V composite tubes. the ultimate tensile strengths of the near-β extruded tubes were about 577 MPa at 600 °C and 329 MPa at 700 °C, which were nearly 50 MPa higher at 600 °C and 30 MPa higher at 700 °C than those of an extruded Ti6Al4V [22]. Meanwhile, the elongation for the extruded tubes increased from 14.7% at ambient temperature to 17.1% at 600 °C and 26.7% at 700 °C, showing an obvious increase of ductility with increasing temperature.

The SEM micrographs of fracture surfaces of the tensile specimens in different conditions are shown in Fig. 8. It can be seen that the prior cracks seem to initiate and propagate along the network boundary of the sintered composites at ambient temperature, which might be referred as intercrystalline fracture. This was consistent with the inferior ductility in Fig. 7. In contrast, abundant dimples and tearing ridges, which are usually characterized as ductile fracture features, were observed in the fracture surfaces for the near-β extruded composites at both ambient and elevated temperatures. The broken TiBw in fracture area at high magnification reflected a strong interfacial bonding between it and the matrix. This indicated that TiBw preferentially bore higher stress than the matrix before fracture. Since the microcrack around TiBw can be easily blunted by the compatible deformation in the adjacent matrix, the fracture occurred at much higher load via microvoids coalescence around the TiBw. This is beneficial to the ductility improvement of the tubes as illustrated in Fig. 7.

Compressive tests were performed to reveal the anti-compression ability of the final tubes, as shown in Fig. 9. The compressive curves of the sintered and near-β extruded composites at ambient temperature exhibited a similar shape with continuous strain hardening, relating to the slight increase of yield strength from 1105 MPa to 1169 MPa. An interpretation may be that the reduced reinforcement effects in transverse section compensate the favorable effect of grain refinement in the matrix. The yield strength in compression sharply decreased to 488 MPa at 600 °C and further to 247 MPa at 700 °C, following the similar trend in tension. In addition, the ratio of the yield strength in tension to the yield strength in compression commonly used to characterize tension/compression asymmetry, also increased from 0.78 at ambient temperature to about 1.0 at 700 °C.

(1) The present study confirms that it is feasible to fabricate thin tubes of 3.5 vol.% TiBw/Ti6Al4V composites by a two-step hot-hydrostatic extrusion composed of β extrusion and subsequent near-β extrusion.

(2) The microstructure consisting of elongated and equiaxed prior β grains has been generated via partial dynamic recrystallization during the process, leading to a refined basket-weave structure at ambient temperature. Synthesized TiBw formed a typical network structure around Ti6Al4V matrix particles after sintering, but then became disperse and simultaneously rotated to the ED with the processing.

(3)Obvious <101>α//ED and <100>α//ED fibers were transformed from the <110>β//ED deformation fiber during the β extrusion, as well as a <112>α//ED fiber from <112>β//ED recrystallization fiber. Furthermore, a similar fibrous texture with a <110>α//ED fiber instead of the <112>α//ED fiber was developed after the subsequent near-β extrusion, resulting from the involvement of α phase in plastic deformation.

(4) The increase in strengths is mainly attributed to the contributions of grain refinement strengthening, TiBw hardening and fibrous texture strengthening. Improved mechanical performance of the final tubes was achieved via the current process with ultimate strength of 1155 MPa, yield strength of 950 MPa and elongation of 14.7% at ambient temperature. High temperature strengths in both tension and compression were also enhanced.

This work was financially supported by the National High-Tech Research and Development Program of China (“863 Program”, No. 2013AA031202).

| 1. |

|

| 2. |

|

| 3. |

|

| 4. |

|

| 5. |

|

| 6. |

|

| 7. |

|

| 8. |

|

| 9. |

|

| 10. |

|

| 11. |

|

| 12. |

|

| 13. |

|

| 14. |

|

| 15. |

|

| 16. |

|

| 17. |

|

| 18. |

|

| 19. |

|

| 20. |

|

| 21. |

|

| 22. |

|