An experimental study of dwell and normal cyclic fatigue behaviours was carried out using specimens from a Ti60 forging with a bimodal microstructure. Apparent decrease in the fatigue life was found under dwell fatigue condition as compared to that under normal cyclic condition. Strain produced in each cycle in dwell fatigued specimens was observed larger than that in its normal cyclic-fatigued counterparts. Interior crack initiation was found in most dwell fatigued specimens as compared to the subsurface crack initiation under normal cyclic fatigue condition. Flat and bright facets were found at crack initiation sites in both cases. The facet density is higher in dwell condition, which is consistent with the crystal orientation and Schmid factors analysis of α grains around secondary cracks using electron back-scattered diffraction (EBSD) methods. Dwell loading favours cleavage in α grains with their basal plane normals aligned no more than 15° to the loading axis, which may account for its lower fatigue life according to the present study.

Near α titanium alloys are used in aerospace applications as discs and blades in the high pressure part of aero engine compressors. Critical disc and blade components experience demanding mechanical conditions during routine operation. A typical flight operation could be broken down into a sequence comprising take off-cruise-landing [1] and [2]. Fatigue performance may be influenced differently by the relatively long term hold or “dwell” at peak stress during a fatigue cycle, depending on alloy type [3]. In the past three decades, significant efforts were made to study dwell fatigue behaviour of titanium alloys [4], [5], [6], [7] and [8].

Many near α titanium alloys suffered from the dwell fatigue-sensitivity problem, such as IMI 834 [9] and [10], IMI 685 [9], IMI 829 [11] and Ti-6242 [3], [6], [12], [13], [14] and [15]. Detailed failure analysis illustrated that the dwell fatigue cracks were inclined to initiate at some distance away from the predicted peak stress locations [16]. The initiation sites were characterized by the presence of “quasi-cleavage facets” and the facet surfaces were remarkably flat and nearly perpendicular to the stress axis.

The origin of dwell fatigue-sensitivity was thought to be associated with such factors as microtexture [1], [15], [16], [17] and [18], brittle hydrides [1], [9] and [14]and “cold” creep [1], [19], [20] and [21]. Formation of brittle hydrides, through the time dependent diffusion of hydrogen under the influence of a hydrostatic stress field, was proposed as a cause of the dwell phenomenon [22]. Creep was normally considered to be a high temperature failure mode [23]. However, it was found that titanium alloys may accumulate strain under static or cyclic load at room temperature due to planar slip damage [20] and [21].

Ti60 is a near α titanium alloy with an operating temperature capability up to 600 °C. An understanding of dwell fatigue mechanism was necessary both for optimizing of microstructure and predicting service life of engine parts. The present study investigated the damage mechanism of Ti60 alloy subjected to dwell and normal cyclic fatigue loading. Orientations of α grains around secondary fatigue cracks near the main crack initiation sites on the longitudinal section were analysed using electron back-scattered diffraction (EBSD) method. The purpose of the present article was to make clear the mechanism underlying dwell fatigue behaviour of Ti60 alloy.

The material used in this study was a Ti60 forging. The final forging operations were conducted in (α + β) phase field. The forging was then solution heat treated at 1010 °C for 2 h in air followed by oil quenching and aged at 700 °C for 2 h followed by air cooling. The yield stress of the material is 940 MPa. Optical microscopy was conducted using a Zeiss Axiovert 200 MAT machine. The microstructure on cross-section of the forging was observed. A bimodal microstructure with globular and elongated α phase embedded in transformed β matrix was shown in Fig. 1(a). The volume fraction of the globular α phase was about 20%. No obvious difference was found among optical microstructures taken from different areas of the Ti60 forging. EBSD orientation maps revealed clustering of similarly orientated grains (also referred to as microtexture [9], [17], [18], [24], [25], [26], [27] and [28]) both in outer and central parts of the forging as shown in Fig. 1(b) and (c), respectively. It can be seen that the area with similarly orientated grains (indicated by ellipses) is somewhat larger in the central parts than that in the outer parts of the forging.

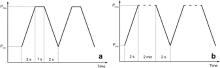

Fatigue tests were conducted on a closed-loop MTS810 servo-hydraulic machine with a maximum load capacity of 100 kN in air at room temperature. All tests were performed under stress control. All fatigue tests proceeded until fracture occurred. Cyclic and 2-min-dwell loading waveforms were illustrated schematically in Fig. 2. The accumulation of strain during fatigue tests was measured by an axial extensometer and recorded automatically by the computer system. The 1 s-holding at peak stress in the normal cyclic fatigue waveform was to facilitate data acquisition.

| Fig. 2. Loading waveforms used in the present work: (a) normal cyclic fatigue waveform; (b) dwell fatigue waveform. |

The specimens used in this study were cut in the tangential direction of the forging. Solid specimens with a cylindrical gauge length of 12 mm and a gauge diameter of 6 mm were used. The gauge length was mechanically polished in the axial direction to minimize surface effects on fatigue life.

In order to study the fatigue mechanism, the fractured specimen was cut longitudinally and secondary cracks around fatigue initiation sites were observed with an Oxford S-3400N scanning electron microscope (SEM) equipped with an EBSD detector.

The optical and SEM samples were ground with 800# and 2000#SiC emery paper in sequence and then electrolytically polished with a mixture composed of methanol, butanol and perchloric acid. The orientation and Schmid factors of the grains around the secondary cracks were examined by EBSD and calculated using a Channel 5 software.

Fatigue data of Ti60 forging under dwell and normal triangle waveforms were given in Table 1. An obviously lower fatigue life was found under dwell fatigue condition. Similar results were observed in other titanium alloys such as Ti-6242, IMI 685, IMI 829 [11] and IMI 834 [3]. It can be seen that dwell fatigue life of samples from the outer part of the forging was longer than that from the central part.

| Table 1. Fatigue data of Ti60 forging under different loading modes |

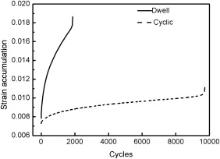

The relationship between strain accumulation and cycles of samples 3 and 4 in Table 1 was plotted in Fig. 3. It can be seen that strain accumulation under dwell fatigue condition was much larger than that under normal cyclic condition. Similar results were found for other specimens. According to the classical fatigue damage accumulation model [29], fatigue failure was resulted from damage accumulation during the cyclic process. The decreased fatigue life under dwell fatigue condition was closely related to the large strain produced in each cycle.

| Fig. 3. Strain accumulation curves under dwell and normal cyclic fatigue conditions, corresponding to samples 3 and 4 in Table 1, respectively. |

Fracture surfaces of samples listed in Table 1 were shown in Fig. 4, in which the arrows pointed to crack initiation sites. Significant difference of fracture surfaces was found. Under normal cyclic fatigue mode crack initiated at the subsurface region, while under dwell fatigue mode crack initiated in the interior of the specimen. Apparent facets were found and the facet density is larger in dwell than that in normal cyclic fatigue condition at the crack initiation site. It was thought that the facet formation was related to crystallographic orientations of α grains relative to the main stress axis [30]. The facets are characterized as “quasi-cleavage facets” [31]. They are not considered to be the result of a brittle fracture mechanism, but instead due to the gradual separation of slip damage concentrated within a persistent planar slip band [1] and [32]. The difference of facet morphology produced in the two fatigue modes was not found.

Secondary cracks produced in the two fatigue modes are shown in Fig. 5. Secondary cracks in normal cyclic-fatigued specimens were nearly perpendicular to the loading axis. A small tilt of about 15° of secondary cracks from the loading axis was found in dwell fatigued specimen, which may imply that fatigue cracks were not only limited to initiate on grains with their basal planes normal to the loading axis, but those having an angel at least between 75° and 105° to the loading axis were also involved. This phenomenon is consistent with the higher facet density found in Fig. 3 under dwell fatigue condition.

| Fig. 5. Orientation maps of grains around secondary cracks: (a, b) dwell fatigued; (c, d, e) normal cyclic-fatigued. |

Schmid factors of {0001}<11–20>, {10–10}<11–20>and {10–11}<11–20>slip systems for grains around secondary cracks in Fig. 5(a) calculated using Channel 5 were listed in Table 2. It can be seen that the grains around the crack initiation sites had high Schmid factor values for basal slip. Similar results were also obtained for Fig. 5(b)–(e). This finding revealed the tendency of facet formation on basal planes.

| Table 2. Schmid factors for grains illustrated in Fig. 5(a) |

Decrease of fatigue life under dwell fatigue condition for titanium alloys is not a new finding since similar phenomena were found in other titanium alloys like IMI 834, Ti 6/4 [33], Ti-6242 [34], while its origin is far from being clarified. According to the findings of the present work, the high strain accumulation may be closely related to the high facet density found around crack initiation sites under dwell fatigue mode. Higher facet density implies more α grains involved in fatigue damage, which resulted in larger strain accumulation during the fatigue process. Because the detailed information about the damage process is still not available, it may be inferred from the much lower fatigue life that more cleavage of similar orientated α grains occurred under dwell fatigue condition, which leads more minor cracks to originate and then progress as compared with normal cyclic fatigue at the same stress level. Coalescence of these minor cracks leads to earlier fatigue fracture under dwell fatigue condition. On this basis, it can be deduced that dwell fatigue life may be related to the amount of similar orientated α grains and distance between them. The more the α grains with their basal plane nearly normal to the nominal stress axis, and the shorter the inter-grain distance, the shorter the fatigue life would be. Local region containing grains with similar orientations was defined as microtexture in literature and is considered to be an important controlling factor on dwell fatigue [27] and one of the causes for the decreased fatigue life. The longer dwell fatigue life of samples from the outer part found in the present study, see Table 1, can be well rationalized according to the smaller area of microtexture existing in this part. However more detailed work is needed to reveal the exact microtexture-sensitive damage process under dwell fatigue condition.

(1) Apparent decrease of fatigue life was found under dwell fatigue condition as compared to that under normal cyclic condition for Ti60 alloy. Strain produced in each cycle in dwell fatigued specimens was obviously larger than that in its normal cyclic-fatigued counterparts.

(2) Obvious difference of fracture surface was found for the two differently fatigued specimens: interior crack initiation was found typically for dwell fatigued specimens as compared to the subsurface crack initiation under normal cyclic fatigue condition. Flat and bright facets were found at crack initiation sites in both cases, while the facet density was higher in the dwell fatigue condition than that in normal cyclic fatigue condition.

(3) EBSD analysis revealed that the grains around the crack initiation sites had high Schmid factor values for basal slip. Under dwell fatigue condition, not only grains with their basal plane perpendicular to the loading axis, but also those with their basal planes at an angel between 75° and 105° to the loading axis were also involved, which may account for the higher facet density found in dwell fatigued fracture surfaces and be closely related to the lower fatigue life under dwell fatigued condition.

| 1. |

|

| 2. |

|

| 3. |

|

| 4. |

|

| 5. |

|

| 6. |

|

| 7. |

|

| 8. |

|

| 9. |

|

| 10. |

|

| 11. |

|

| 12. |

|

| 13. |

|

| 14. |

|

| 15. |

|

| 16. |

|

| 17. |

|

| 18. |

|

| 19. |

|

| 20. |

|

| 21. |

|

| 22. |

|

| 23. |

|

| 24. |

|

| 25. |

|

| 26. |

|

| 27. |

|

| 28. |

|

| 29. |

|

| 30. |

|

| 31. |

|

| 32. |

|

| 33. |

|

| 34. |

|